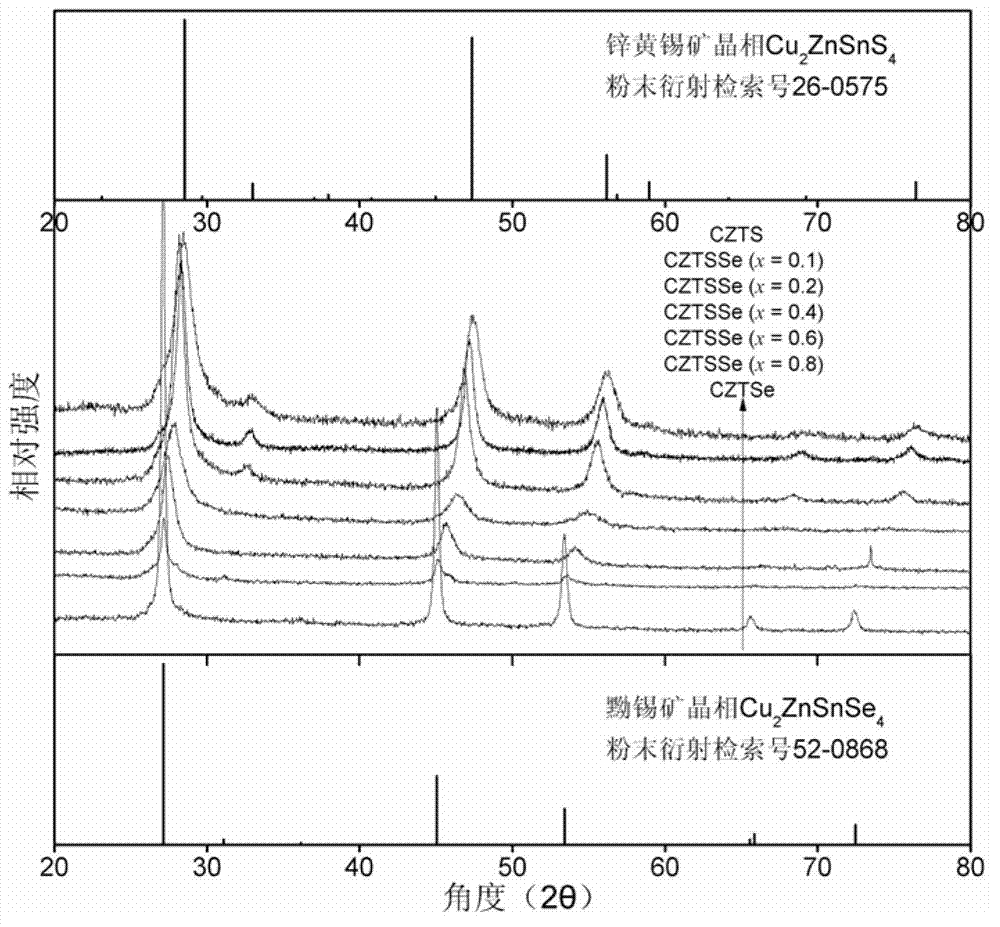

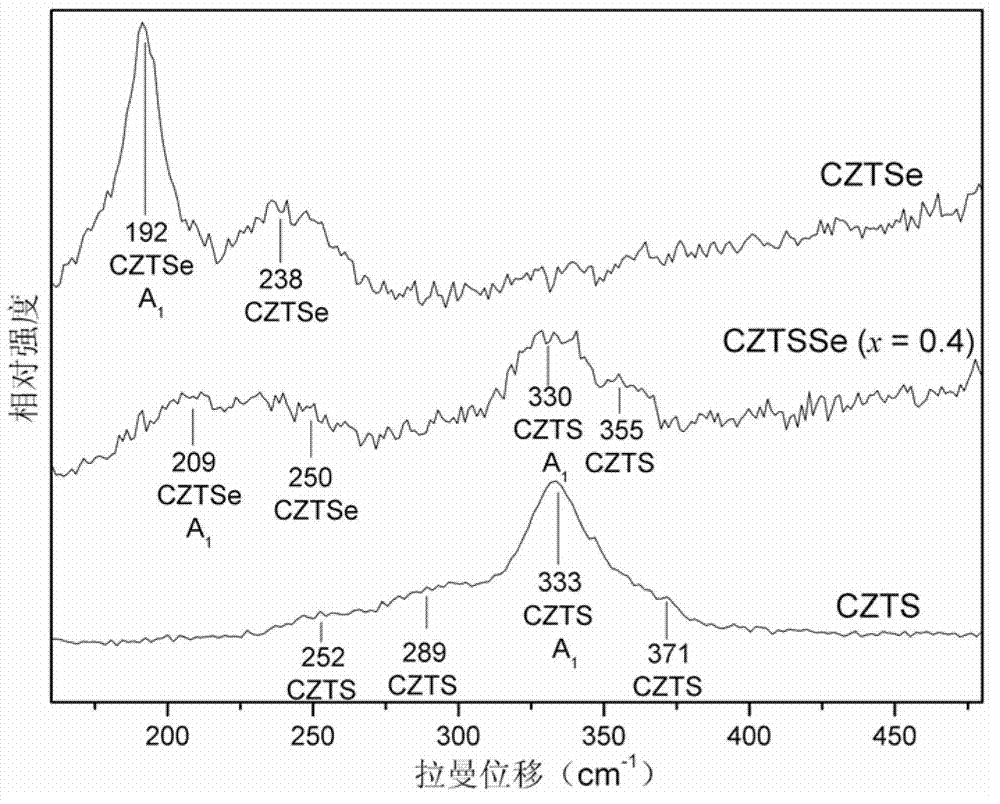

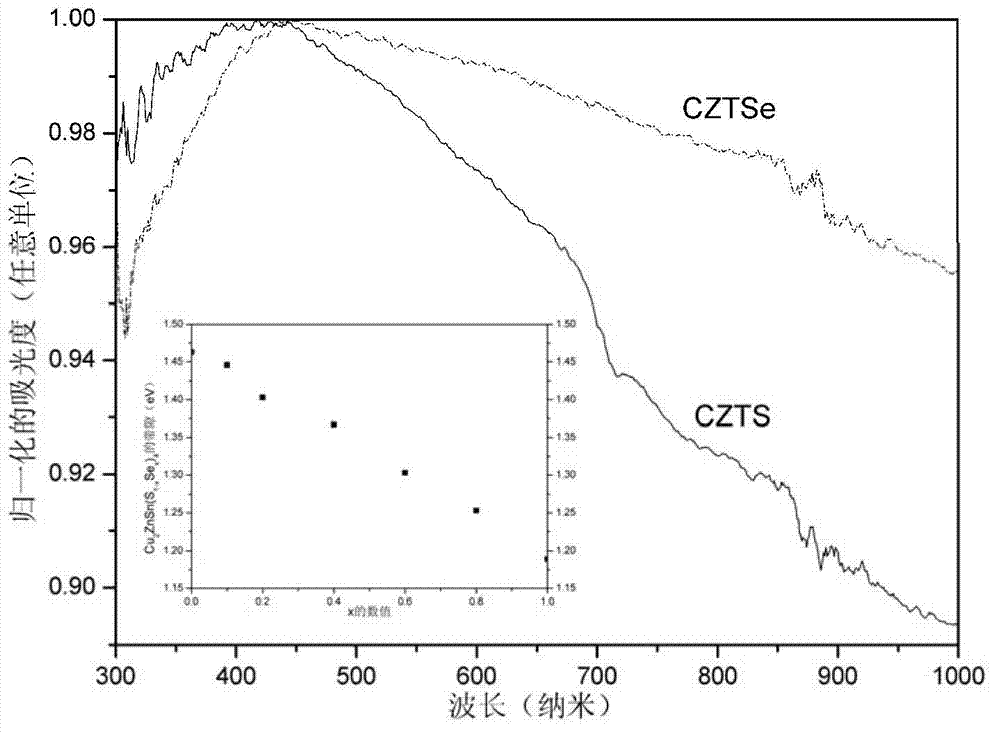

Method for synthesis of band gap-adjustable monodispersed Cu2ZnSn(S1-xSex)4 nano-crystals by crystal phase control

A nanocrystalline, monodisperse technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of high cost of oleylamine, impact on environmental protection, high cost of battery materials, etc., and achieve the purpose of inhibiting rapid growth Large, easy to operate, and the effect of inhibiting agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides a pure-phase monodisperse Cu 2 ZnSnS 4 The preparation method of nanocrystals (abbreviated as CZTS nanocrystals), the steps are as follows:

[0046] 1. Weigh CuCl powder and ZnCl according to the molar ratio of 2:1:4 2 Powder, S powder, put into a three-necked flask, pour glycerol (or a mixture of glycerol and ethylene glycol, polyethylene glycol and other common solvents) and oleylamine as a solvent (oleylamine accounts for the total solvent volume 5%), the ratio of the total solvent volume to the moles of the final CZTS was 20 mL: 1 mmol, and the flask was filled with N 2 Exhaust air and use it as protective gas all the time, heat to 80°C while stirring, press ZnCl 2 : SnCl 4 =1:1 molar ratio to take SnCl 4 The liquid was injected under the liquid surface of the reaction liquid, and the temperature was raised to 120°C to 140°C for 1 hour.

[0047] 2. Raise the temperature to 210°C at 2.5°C / min, react at this temperature for 30 to 60 minu...

Embodiment 2

[0051] This embodiment provides a pure-phase monodisperse Cu 2 ZnSnS 4 The preparation method of nanocrystals (abbreviated as CZTS nanocrystals), the steps are as follows:

[0052] 1. Weigh CuCl powder and ZnCl according to the molar ratio of 2:1:1:4 2 Powder, SnCl 4 ·5H 2 Put O powder and S powder into a three-necked flask, pour glycerol (or a mixture of glycerol and ethylene glycol, polyethylene glycol and other common solvents) and oleylamine as a solvent (oleylamine accounts for the total solvent 5% by volume), the ratio of the total solvent volume to the molar number of the final CZTS was 20 mL: 1 mmol, and the flask was filled with N 2 The air was exhausted and kept as protective gas, and heated to 120°C to 140°C for 1 hour while stirring.

[0053] 2. Raise the temperature to 210°C at 2.5°C / min, react at this temperature for 30 to 60 minutes, put the reaction flask in the air and cool it to below 80°C, and transfer the fluid reaction solution to a centrifuge filled ...

Embodiment 3

[0057] This embodiment provides a pure-phase monodisperse Cu 2 ZnSn(S 0.8 Se 0.2 ) 4 The preparation method of nanocrystals (abbreviated as CZTSSe nanocrystals), the steps are as follows:

[0058] 1. Weigh the CuCl powder and ZnCl according to the molar ratio of 2:1:3.2:0.8 2 Powder, S powder, Se powder, put into a three-necked flask, pour glycerol (or a mixture of glycerol and ethylene glycol, polyethylene glycol and other common solvents) and oleylamine as a solvent (oleylamine accounts for The total solvent volume is 10%), the ratio of the total solvent volume to the moles of the final CZTSSe is 30 mL: 1 mmol, and the flask is filled with N 2 Exhaust air and use it as protective gas all the time, heat to 80°C while stirring, press ZnCl 2 : SnCl 4 =1:1 molar ratio to take SnCl 4 The liquid was injected under the liquid surface of the reaction liquid, and the temperature was raised to 120°C to 140°C for 1 hour.

[0059] 2. Raise the temperature to 220°C at 2.5°C / min, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com