Preparation method of boron nano-particles

A nanoparticle, butaborane technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as boron nanoparticles that have not yet been seen, and achieve high output, simple production process, The effect of uniform size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Turn on the vacuum pump, purge the plasma chamber and gas path with nitrogen, and evacuate to reduce the pressure in the plasma system to about 1Pa. Argon (Ar) gas is first introduced into the plasma chamber from the outer tube of the gas inlet pipe at a flow rate of 500 sccm (sccm means 1 cubic centimeter per minute at 0° C. and 1 standard atmospheric pressure). Turn on the radio frequency source, adjust the power to 200W, and generate argon plasma; then pass into the diborane (B 2 h 6 ) gas, the air pressure in the plasma chamber is controlled at 500Pa, and the RF source matching box is adjusted so that the load power and the load power are fully matched. The prepared boron nanoparticles were collected by filter bags.

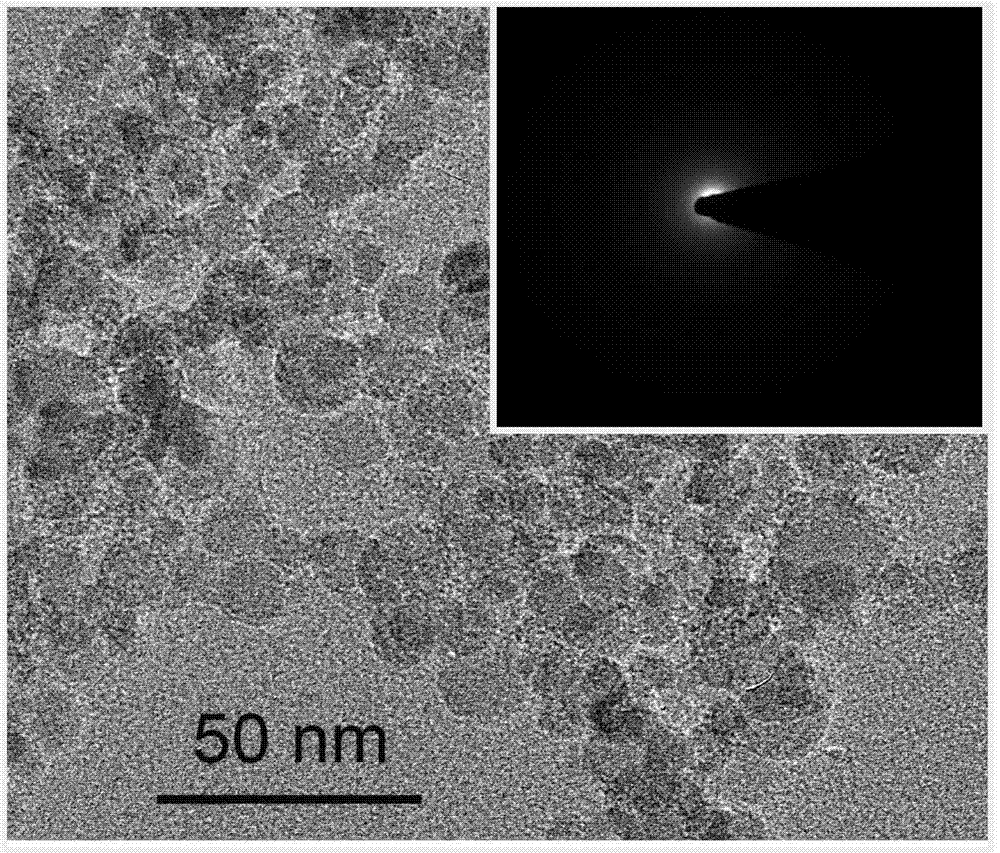

[0026] figure 1 The transmission electron micrograph (TEM) photo and the diffraction picture of the boron nanopowder collected, the result shows that the average size of the boron nanoparticle is 11nm, and the standard deviation of the size distribu...

Embodiment 2

[0029] Turn on the vacuum pump, purge the plasma chamber and gas path with nitrogen, and evacuate to reduce the pressure in the plasma system to about 1Pa. Helium (He) gas is introduced into the plasma cavity from the outer tube of the intake pipe at a flow rate of 100 sccm. Turn on the radio frequency source, adjust the power to 80W, and generate helium plasma; Then, the tetraborane (B 4 h 10 ) gas, the air pressure in the plasma chamber is controlled at 1200Pa, and the RF source matching box is adjusted so that the load power and the load power are fully matched. The prepared boron nanoparticles were collected by filter bags.

[0030] The prepared nanoparticles can be determined as amorphous boron nanoparticles through transmission electron microscopy, X-ray diffraction, X-ray photoelectron spectroscopy, plasma mass spectrometry and other analysis methods. The average size of boron nanoparticles is 46nm, and the standard deviation of the size distribution is 18% of its av...

Embodiment 3

[0032] Turn on the vacuum pump, purge the plasma chamber and gas path with nitrogen, and evacuate to reduce the pressure in the plasma system to about 1Pa. Argon gas (Ar) is first introduced into the plasma cavity from the outer pipe of the gas inlet pipe at a flow rate of 3000 sccm. Turn on the radio frequency source, adjust the power to 850W to generate argon plasma; then pass into the diborane (B 2 h 6 ) and hydrogen (H 2 ), wherein diborane (B 2 h 6 ) and hydrogen (H2 ) with a volume ratio of 7:2, and the air pressure in the plasma chamber was controlled at 4000Pa. Adjust the RF source matching box to make the load power fully match the loading power. The prepared boron nanoparticles were collected by filter bags.

[0033] The prepared nanoparticles can be determined as amorphous boron nanopowder particles through transmission electron microscope, X-ray diffraction, X-ray photoelectron spectroscopy, plasma mass spectrometry and other analysis methods. The average siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com