High-toughness polyvinyl chloride tube

A technology of polyvinyl chloride and chlorinated polyvinyl chloride, which is applied in the direction of rigid pipes, pipes, pipes/pipe joints/pipe fittings, etc., and can solve the problem of reduced impact strength of hard polyvinyl chloride plastic drainage pipes and impact resistance of PVC pipes Poor, tensile strength decline and other problems, to achieve the effect of improving aging resistance, improving smoothness of lubrication, and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

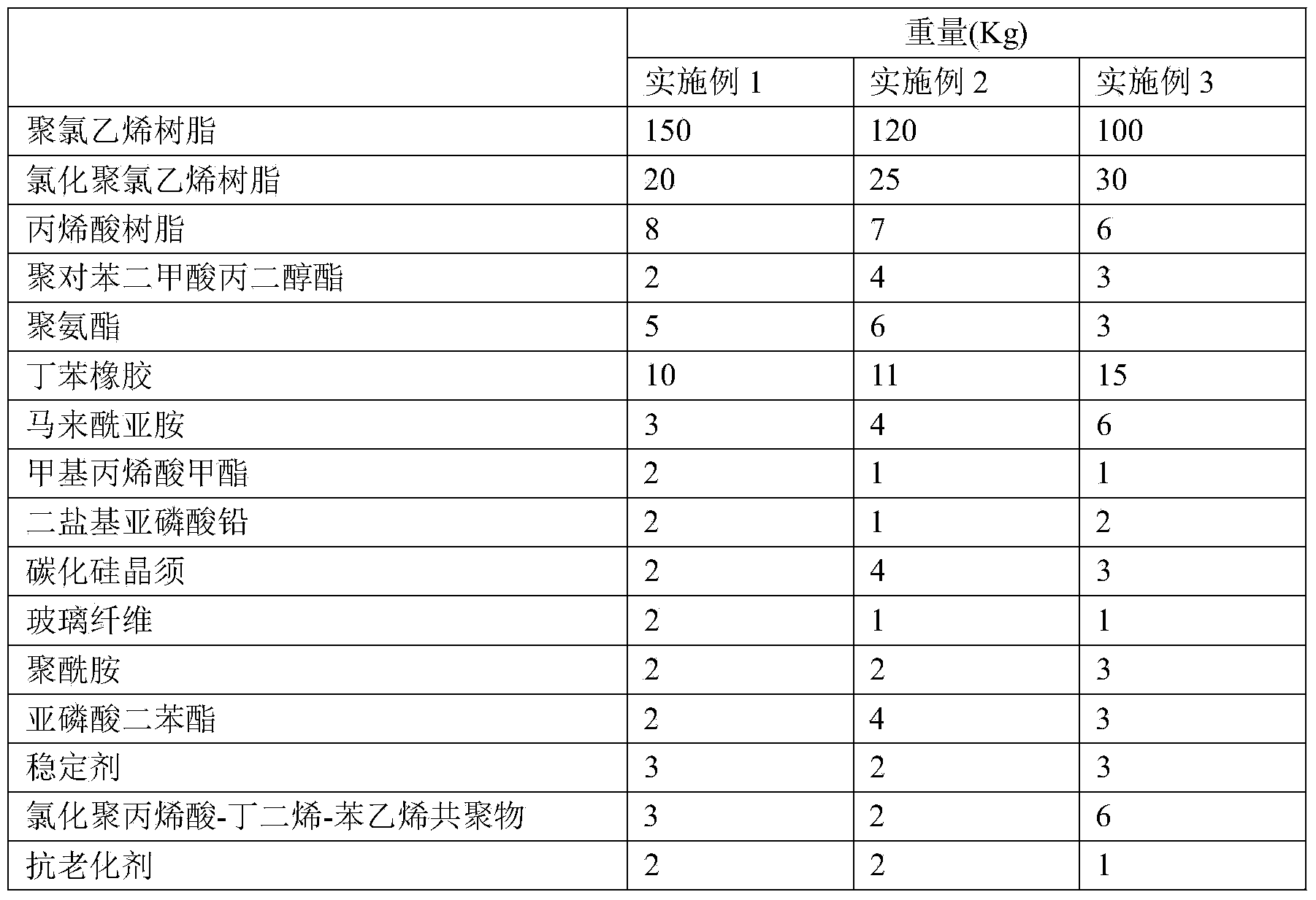

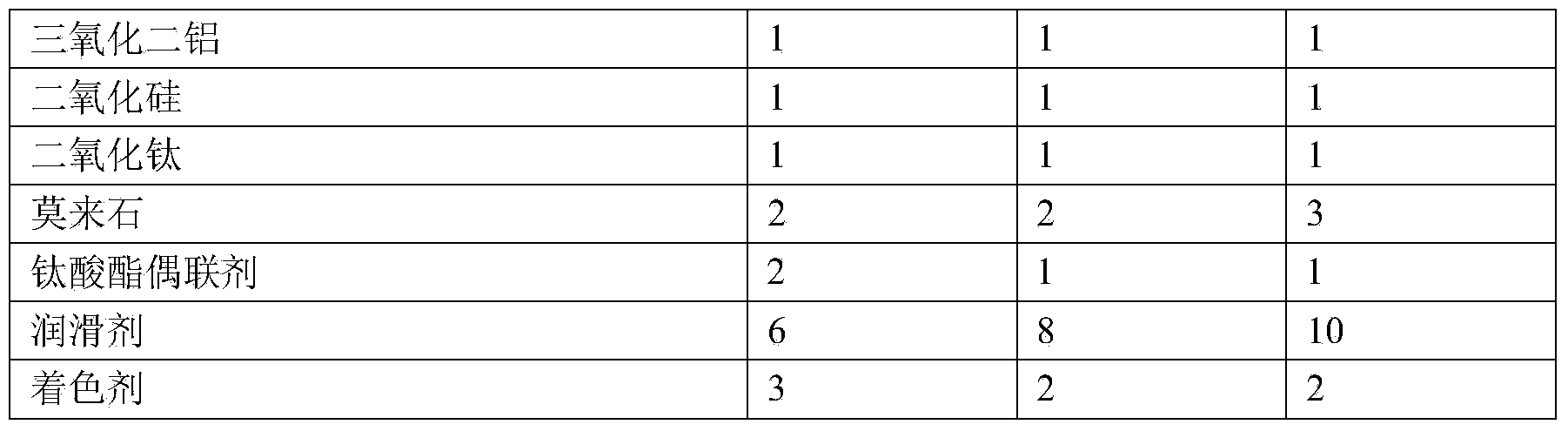

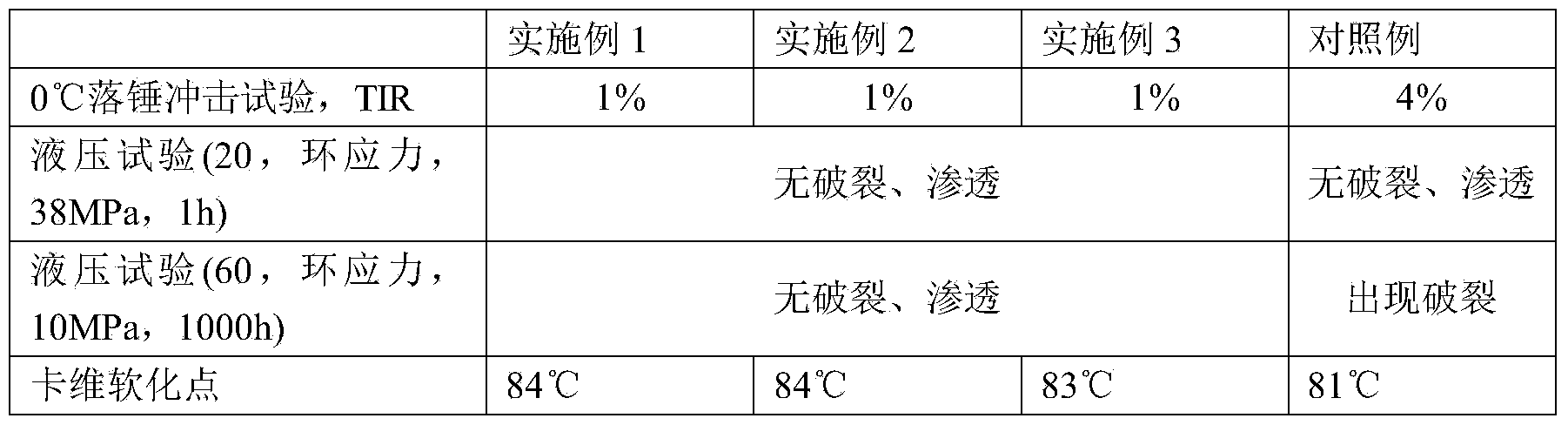

[0016] The components were prepared in the weight ratios shown in Table 1.

[0017] The weight proportion of table 1 embodiment 1~embodiment 3

[0018]

[0019]

[0020] The chlorine content of the above-mentioned chlorinated polyvinyl chloride resin is 61-65%.

[0021] The aforementioned stabilizers are organotin stabilizers.

[0022] The lubricant mentioned above is paraffin polyethylene wax.

[0023] The above-mentioned colorant is carbon black.

[0024] The preparation method of above-mentioned high tenacity polyvinyl chloride pipe is:

[0025] S1: Weigh each component in proportion, mix evenly at a temperature of 90-110°C, and keep warm for 20 minutes;

[0026] S2: Put the mixture obtained in S1 into the conical twin-screw extruder, the body temperature is 150°C, the first zone is 180°C; the second zone is 190°C; the third zone is 195°C; the fourth zone is 200°C; the fifth zone is 210°C; 30rpm; feeder speed is 20rpm;

[0027] S3: Vacuum sizing, forming, cuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com