Method for leaching potassium in phosphorus potassium associated ore at low temperature by assisting with microwaves/ultrasonic waves

A technology of phosphorus and potassium associated ore and ultrasonic technology, which is applied in the field of low-grade leaching of potassium in phosphorus and potassium associated ore assisted by microwave/ultrasonic wave, and extraction of potassium in low-grade phosphorus and potassium associated ore. Problems such as difficult breeding and domestication are difficult to achieve the effects of enhancing material transfer, shortening heat conduction time, and reducing reaction activation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

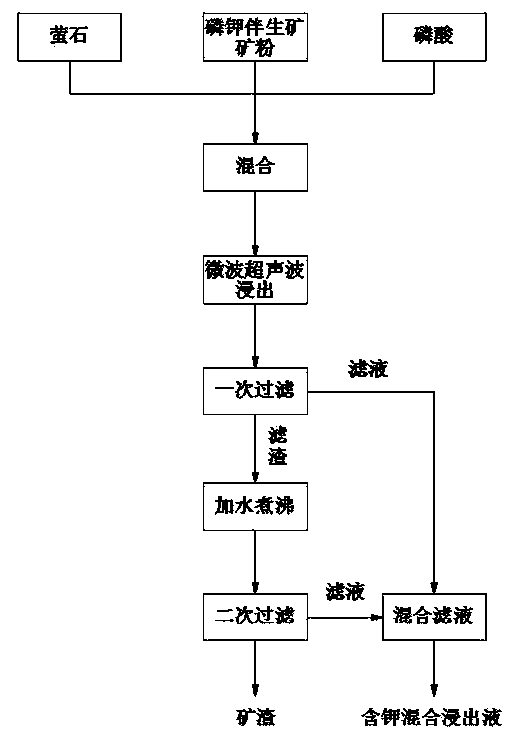

Method used

Image

Examples

Embodiment 1

[0026] The ore in the embodiment of the present invention is the phosphorus-potassium associated ore that comes from collophosite and potassium feldspar in the Yiling area of Yichang, Hubei, and contains K 2 O 8.63%, P 2 o 5 6.63%, SiO 2 55.48%, Al 2 o 3 13.42%, CaO 5.46%, Fe 2 o 3 3.84%, Na 2 O 1.34%, MgO 1.13% phosphorus and potassium associated ore.

[0027] 1) Ingredients: Take the dry -180 mesh phosphorus and potassium associated ore powder and the additive fluorite, mix evenly, then add phosphoric acid to soak, the amount of fluorite added is 29% of the mass of phosphorus and potassium associated ore powder, and the mass percentage concentration of phosphoric acid It is 60%, and its addition is 9mL / g phosphate and potassium associated mineral powder, obtains mixture;

[0028] 2) Microwave leaching: Place the homogeneously mixed mixture in step 1) in a microwave reactor, heat it with 2450MHz microwave irradiation, the total microwave power is 440W, replenish...

Embodiment 2

[0034] The ore in the embodiment is a phosphorus-potassium associated ore from the symbiotic collophosite and potassium feldspar in the Yiling area of Yichang, Hubei, containing K 2 O 8.63%, P 2 o 5 6.63%, SiO 2 55.48%, Al 2 o 3 13.42%, CaO 5.46%, Fe 2 o 3 3.84%, Na 2 O 1.34%, MgO 1.13% phosphorus and potassium associated ore.

[0035] 1) Ingredients: Take the dry -180 mesh phosphorus and potassium associated ore powder and the additive fluorite, mix evenly, then add phosphoric acid to soak, the amount of fluorite added is 29% of the mass of phosphorus and potassium associated ore powder, and the mass percentage concentration of phosphoric acid is 60%, and the addition is 9mL / g phosphorus and potassium associated mineral powder to obtain a mixture;

[0036] 2) Ultrasonic leaching: heat the uniformly mixed mixture in step 1) on an electric heating mantle, set the temperature to 120°C, use 40kHz ultrasonic treatment, ultrasonic power is 500W, add water every 30min,...

Embodiment 3

[0042] The ore in the embodiment of the present invention is the phosphorus-potassium associated ore that comes from collophosite and potassium feldspar in the Yiling area of Yichang, Hubei, and contains K 2 O 8.63%, P 2 o 5 6.63%, SiO 2 55.48%, Al 2 o3 13.42%, CaO 5.46%, Fe 2 o 3 3.84%, Na 2 O 1.34%, MgO 1.13% phosphorus and potassium associated ore.

[0043] 1) Ingredients: Take the dry -180 mesh phosphorus and potassium associated mineral powder and mix them evenly, then add phosphoric acid for soaking. The amount of fluorite added is 30% of the mass of phosphorus and potassium associated mineral powder. It is 65%, and its addition is 15mL / g phosphorus and potassium associated ore slag powder, obtains mixture;

[0044] 2) Microwave leaching: Place the homogeneously mixed mixture in step 1) in a microwave reactor, heat it with 916MHz microwave irradiation, the total microwave power is 900W, replenish water to the original volume every 30min, and the reaction tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com