Filtering material for mask and method for manufacturing filtering material

A technology for filter materials and masks, which is applied in the field of polymer nanofiber filter materials for masks and its preparation, can solve the problems of poor dustproof effect of masks, high quality of filter materials, poor air permeability of masks, etc., and achieve excellent air permeability, preparation method The effect of simplicity and excellent air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

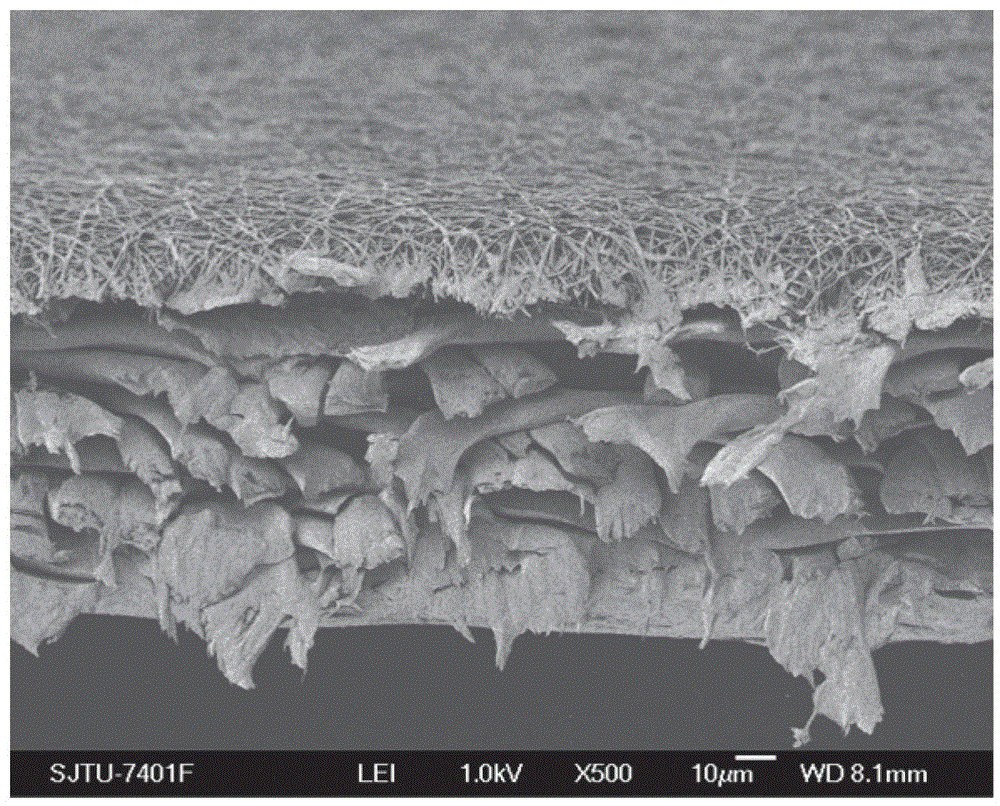

[0027] Dissolve 2.000g of polyvinylidene fluoride in a mixed solvent of 2.677g of N,N-dimethylacetamide and 10.708g of acetone. After the solution is uniformly mixed, the solution of polyvinylidene fluoride nanofibers is electrospun by solution Spun on a 2 g support meltblown nonwoven. The cross-sectional view of the prepared mask filter material is as follows: figure 1 shown. In the prepared filter material for masks, the weight ratio of polyvinylidene fluoride nanofibers and support body melt-blown non-woven fabric is 1:10; and the thickness of polyvinylidene fluoride nanofiber layer is 25um, The average diameter of the ethylene nanofibers was 355 nm. The filter material is tested by the sodium flame method, and the retention rate of sodium chloride aerosol particles is 89.8%, and the pressure drop is 35.2mm water column.

Embodiment 2

[0029] 1.000g of polyvinyl alcohol was dissolved in 10.000g of water, and after the solution was mixed uniformly, the aqueous solution of the polyvinyl alcohol nanofiber was spun on 2g of support body melt-blown non-woven fabric by solution electrospinning. In the filter material for the prepared mask, the weight ratio of polyvinyl alcohol nanofibers and support body melt-blown nonwoven fabric is 1:5; The average diameter is 330 nm. After testing, the retention rate of the filter material to sodium chloride aerosol particles is 90.5%, and the pressure drop is 40.2mm water column.

Embodiment 3

[0031] Dissolve 1.000g of polylactic acid in a mixed solvent of 9.000g of dichloromethane and 0.500g of ethanol. After the solution is uniformly mixed, the solution of polylactic acid nanofibers is spun on 2g of support body spunbonded nonwoven by solution electrospinning. on cloth. In the obtained filter material for mouth mask, the weight ratio of polylactic acid nanofibers and support body spunbonded nonwoven fabric is 3: 10; and, the thickness of polylactic acid nanofiber layer is 30um, and the average diameter of polylactic acid nanofibers is 1000nm. After testing, the retention rate of the filter material for sodium chloride aerosol particles is 79.8%, and the pressure drop is 38.8mm water column.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com