Zero emission online circulation treatment system for electroplated nickel containing waste water

A cyclic treatment, zero-discharge technology, applied in energy wastewater treatment, metallurgical wastewater treatment, heating water/sewage treatment, etc., can solve the problems of increasing the chemical composition of wastewater, unable to realize online recycling of nickel-containing wastewater, etc., and achieve a high degree of automation , Improve the service life and relieve the operating pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the following, the present invention will be further clarified with reference to the accompanying drawings and specific embodiments. It should be understood that these embodiments are only used to illustrate the present invention and not to limit the scope of the present invention. After reading the present invention, those skilled in the art will understand various aspects of the present invention. Modifications in equivalent forms fall within the scope defined by the appended claims of this application.

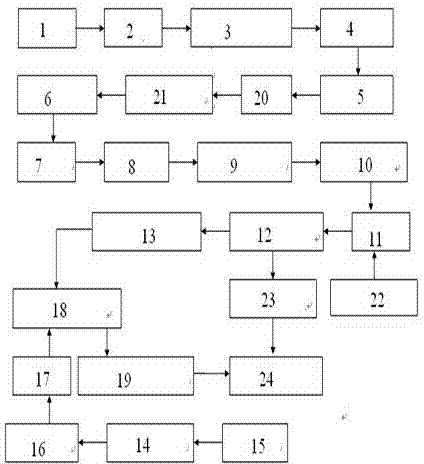

[0025] Such as figure 1 As shown, a zero-discharge on-line recycling treatment system for nickel-containing electroplating wastewater includes: a preliminary pretreatment system, a filtration permeation system and an evaporation concentration system;

[0026] The pre-treatment system includes the original water tank (1), booster pump (2), MBR membrane treatment device (3), bag filter (4), oil removal filter (5), security filter (6) , The original pool (1) is connected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com