Olefin polymerization supported metallocene catalyst and preparation method thereof

A technology for metallocene catalysts and olefin polymerization, applied in the field of supported metallocene catalysts and their preparation, can solve the problems of low utilization rate of metallocene compounds, reduction of active centers, multiple prices, etc., and achieve activity maintenance, reduced dosage, and uniform distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

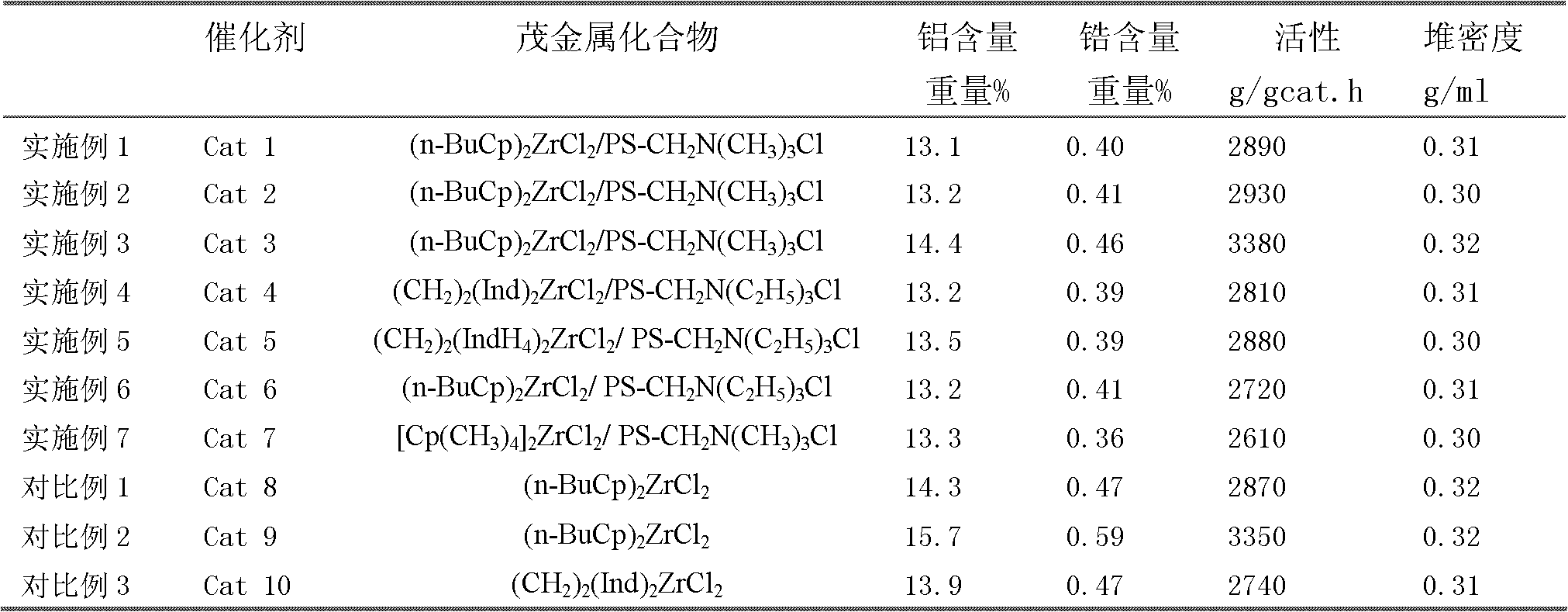

Examples

Embodiment 1

[0024] Preparation of alkylammonium methylated polystyrene chlorides: the same preparation method was used in Examples 1-3 to obtain trimethylammonium methylated polystyrene chlorides with different molar contents of ammonium functional groups.

[0025] In a 500ml round bottom flask, add 10g of chloromethylated polystyrene resin containing 8% divinylbenzene (chloromethyl molar content is 12%), add 120ml trimethylammonium, and react at room temperature for 4 hours, The solid obtained after filtration was vacuum-dried at 110° C. for 12 hours to obtain 10.6 g of trimethylammonium methylated polystyrene chloride, and the molar content of ammonium groups was 11.6%.

[0026] 21.0 grams of Davison955 silica carrier from Grace Company (specific surface area 300 m2 / g, pore volume 1.58 ml / g, average particle size 46 μm) was placed in a muffle furnace and calcined at 600° C. for 6 hours under nitrogen protection. Add the treated silica to a 500ml nitrogen-substituted reactor, add 90ml of...

Embodiment 2

[0028] 21.0 g of Davison955 silica carrier from Grace Company was placed in a muffle furnace and calcined at 600° C. for 6 hours under the protection of nitrogen. Add the treated silica to a 500ml nitrogen-substituted reactor, add 90ml of 10% (mass percent) methylalumoxane (produced by PetroChina Lanzhou Chemical Research Center) in toluene, and stir at 20°C for 1 hour. In another 250ml flask, add 0.56g (n-BuCp) 2 ZrCl 2 (bis-n-butylcyclopentadienyl zirconium dichloride) metallocene compound, 80ml toluene and 1.9 grams of trimethylammonium methylated polystyrene chloride (ammonium molar content is 11.6%, 8% DVB), stirred for 1 Hour. Add the metallocene compound reaction liquid to the silica slurry treated with methylaluminoxane, keep the temperature of the reactor at 20°C, stir for 0.5 hours, then react at -20°C for 3 hours, remove the solvent after the reaction, After drying, a pale yellow free-flowing powder was obtained, designated as cat2. The aluminum content is 13.2%...

Embodiment 3

[0030] 19.8 grams of Davison955 silica carrier from Grace Company was calcined in a muffle furnace at 600° C. for 6 hours under the protection of nitrogen. The treated silicon dioxide was added to a 500 ml reactor replaced with nitrogen, 105 ml of 10% (mass percent) methylaluminoxane toluene solution was added, and stirred at 20° C. for 1 hour. In another 250ml flask, add 0.61 g (n-BuCp) 2 ZrCl 2 (bis-n-butylcyclopentadienyl zirconium dichloride) metallocene compound, 80ml toluene and 1.9 grams of trimethylammonium methylated polystyrene chloride (ammonium molar content is 11.6%, 8% DVB), stirred for 1 Hour. Add the metallocene compound reaction liquid to the silica slurry treated with methylaluminoxane, keep the temperature of the reactor at 20°C, stir for 0.5 hours, then react at -20°C for 3 hours, remove the solvent after the reaction, After drying, a pale yellow free-flowing powder was obtained, designated as cat3. The aluminum content is 14.4% by weight and the zircon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com