Engineering bacteria for producing peptidoglycan in high yield and application thereof

A peptidoglycan and engineering bacteria technology, applied in bacteria, microorganism-based methods, microorganisms, etc., can solve the problems of low peptidoglycan yield, slow growth of strains, and high fermentation cost, and achieve stable genetic shape and short growth cycle. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: Screening of aerobic acidophilus lactobacillus

[0043] (1) Activation and cultivation of bacterial strains

[0044] The original strain of Lactobacillus acidophilus (CGMCC 1.1878) was purchased from the China General Microorganism Culture Collection and Management Center, inoculated in 10% skim milk, activated twice at 37°C for 24 hours, and then inserted into MRS liquid medium with 4% inoculum After 24 hours of subculture in medium, set aside.

[0045] (2) Gradual aerobic domestication of Lactobacillus acidophilus

[0046] Lactobacillus acidophilus LA 0 As the starting strain, in MRS liquid medium (CO 2 17%), 37 ° C enrichment culture for 24 hours, the obtained enrichment solution was spread on the MRS agar plate, placed in CO 2 Cultivate in 17% anaerobic incubator; pick a single colony and inoculate it in MRS liquid medium for microanaerobic culture (CO 2 15%+O 2 2%), the prepared bacterial solution was spread on the MRS agar plate, and placed in...

Embodiment 2

[0048] Embodiment 2: the screening of thermostable Lactobacillus acidophilus mutant strain

[0049] (1) 60 Co-γ-ray mutagenic breeding

[0050] Lactobacillus LA n -1 bacterial solution, centrifuged at 6000r / min for 10min, washed the precipitate twice with sterile normal saline, collected the bacteria and suspended in sterile normal saline to make a concentration of 10 8 Each / mL bacterial solution was used for mutagenesis, and the mutagen dose was 1400Gy.

[0051] (2) Chemical mutation breeding

[0052] Prepare fresh aerobic Lactobacillus LA with 0.1mol / L phosphate buffer (pH7.0) n -2 bacteria suspension, the cell concentration was controlled at 10 8 About one / mL, add 1.0% (v / v) diethyl sulfate (DES), mix well, and bathe in water at 37°C for 40 minutes, add an equal volume of terminator 2% sodium thiosulfate to terminate the mutagenesis, 6000r / min centrifuged for 10min, then washed the pellet twice with phosphate buffer, and finally diluted the cells with physiological s...

Embodiment 3

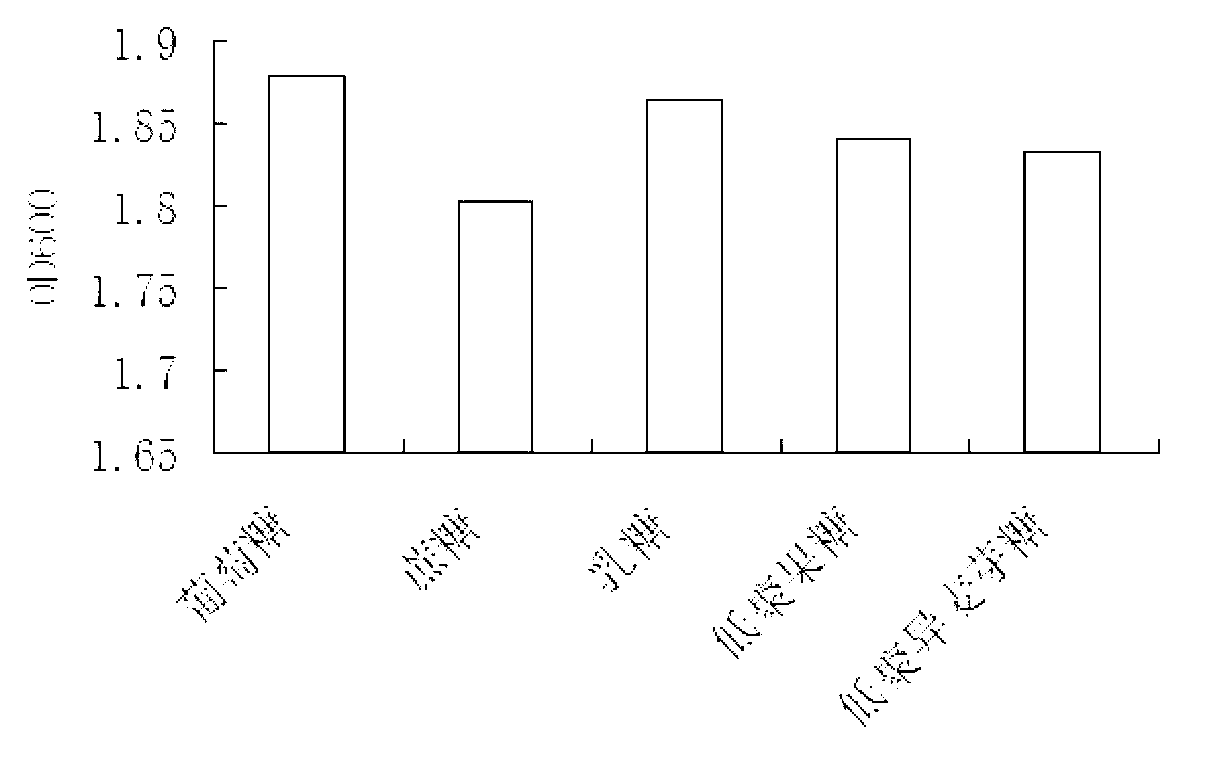

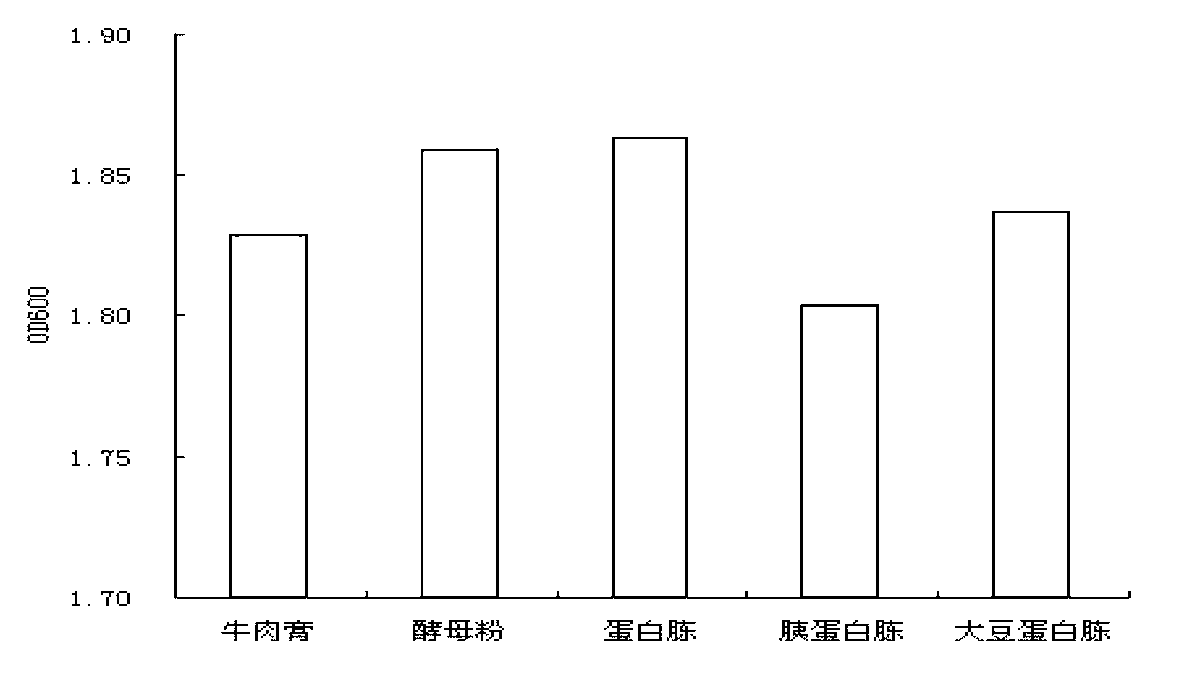

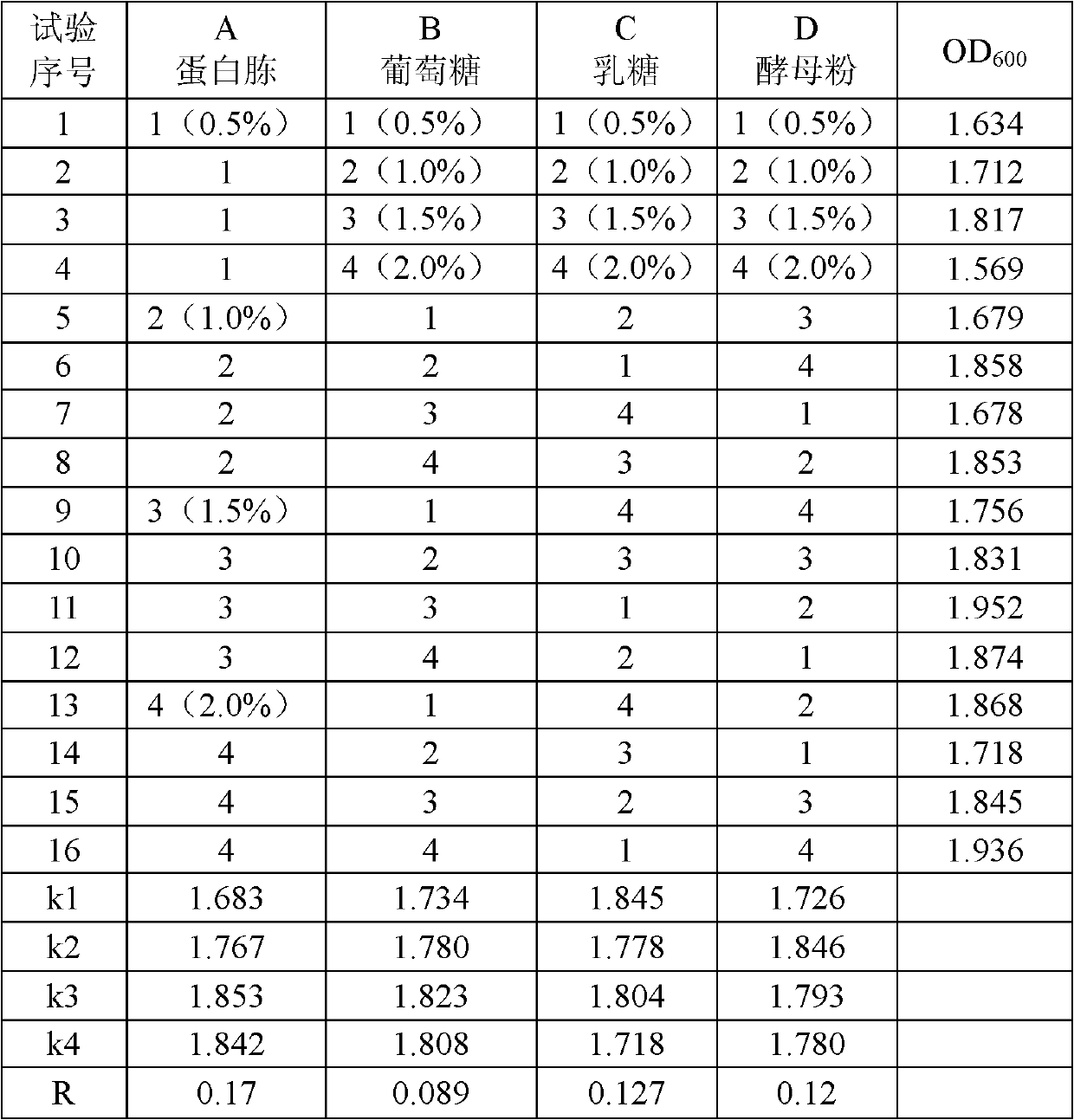

[0061] Embodiment 3: the optimization of fermentation medium (enrichment medium)

[0062] (1) Determination of culture pH conditions

[0063] Considering that the production process requires that the medium must be based on high cell yield and easy separation and harvesting of cells, MRS medium, which is easy to separate cells, was selected as the basic fermentation medium, and optimized and improved on this basis.

[0064] Adjust the initial pH of the culture medium with sterile HCl or NaOH solution to obtain a series of culture media with different pH values, culture at 37°C for 24 hours at 4% inoculum size, and detect the number of viable bacteria. Finally, the initial pH value of the culture medium was determined to be 6.4. (See Table 1)

[0065] Table 1 The effect of initial pH value on the viable count of hzsb strain

[0066] initial pH

Viable count (10 9 cfu / mL)

5.6

4.52

5.8

5.76

6.0

6.83

6.2

7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com