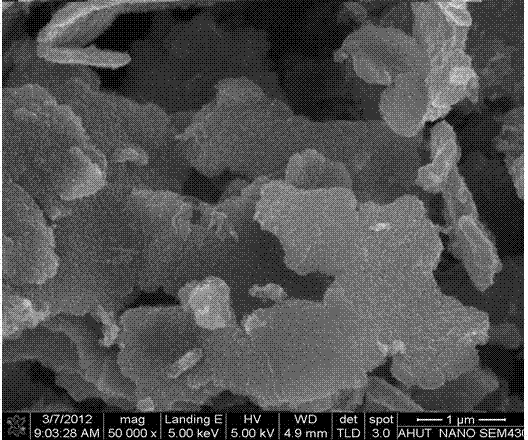

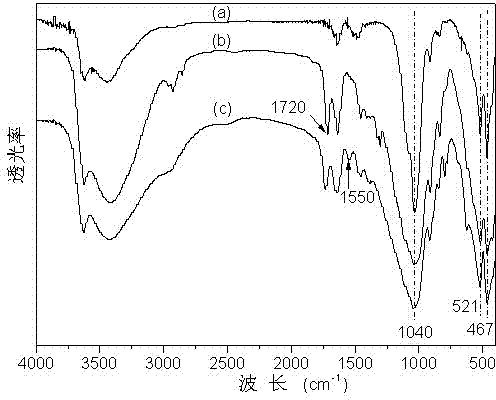

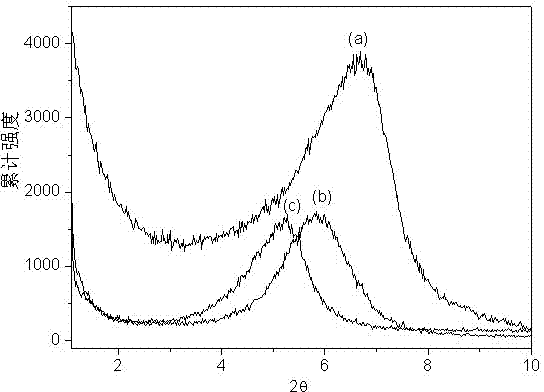

Preparation method of polyaniline/montmorillonite composite adsorbent with sheet structure

A sheet-like structure, montmorillonite technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of easy agglomeration, difficult recovery, low adsorption efficiency, etc., to achieve controllable conditions, The effect of simple preparation process and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] First, disperse 1.0g of sodium montmorillonite in 50mL of water, adjust the pH of the solution to 3 by adding hydrochloric acid dropwise, add 0.5g of polymerizable polyhydroxy tertiary amine modifier, stir for 6 hours, filter and wash with water until there is no chloride ion Obtain organically modified montmorillonite; disperse the organically modified montmorillonite in 50 mL of water, add 1.0 g of 2-acrylamide-2-methylpropanesulfonic acid and 0.008 g of ammonium persulfate, react at 70 ° C for 4 h, and The product was filtered and washed with water to obtain polymeric acid-modified montmorillonite; the polymeric acid-modified montmorillonite was dispersed in 800mL of 0.5mol / L hydrochloric acid aqueous solution, 10g of aniline monomer was added, and after stirring and mixing for 30min, the dissolved 24.5 g of ammonium persulfate in 0.5 mol / L hydrochloric acid aqueous solution was slowly added dropwise, polymerized at room temperature for 24 hours, collected the product...

Embodiment 2

[0036]First, disperse 2.5g of sodium montmorillonite in 100mL of water, adjust the pH of the solution to 3 by adding hydrochloric acid dropwise, add 1.5g of polymerizable polyhydroxy tertiary amine modifier, stir for 6 hours, filter and wash with water until there is no chloride ion Obtain organically modified montmorillonite; disperse organically modified montmorillonite in 100mL water, add 2.5g 2-acrylamide-2-methylpropanesulfonic acid and 0.025g ammonium persulfate, react at 70°C for 4h, and The product was filtered and washed with water to obtain polymeric acid-modified montmorillonite; the polymeric acid-modified montmorillonite was dispersed in 800mL of 0.5mol / L hydrochloric acid aqueous solution, 10g of aniline monomer was added, and after stirring and mixing for 30min, the dissolved 24.5 g of ammonium persulfate in 0.5 mol / L hydrochloric acid aqueous solution was slowly added dropwise, polymerized at room temperature for 24 hours, collected the product, and washed the p...

Embodiment 3

[0040] First, disperse 5.0g of sodium montmorillonite in 150mL of water, adjust the pH of the solution to 2 by adding hydrochloric acid dropwise, add 2.5g of polymerizable polyhydroxy tertiary amine modifier, stir for 6 hours, filter and wash with water until there is no chloride ion Obtain organically modified montmorillonite; disperse the organically modified montmorillonite in 150 mL of water, add 5.0 g of 2-acrylamide-2-methylpropanesulfonic acid and 0.03 g of ammonium persulfate, react at 70 ° C for 4 h, and The product was filtered and washed with water to obtain polymeric acid-modified montmorillonite; the polymeric acid-modified montmorillonite was dispersed in 800mL of 0.5mol / L hydrochloric acid aqueous solution, 10g of aniline monomer was added, and after stirring and mixing for 30min, the dissolved 24.5 g of ammonium persulfate in 0.5 mol / L hydrochloric acid aqueous solution was slowly added dropwise, polymerized at room temperature for 24 hours, collected the produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Adsorption rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com