Lead-acid battery cathode and preparation method thereof

A lead-acid battery and negative electrode technology, applied in the field of lead-acid battery negative electrode and its preparation, can solve the problems of battery performance degradation, battery performance impact, battery damage, etc., achieve simple manufacturing process, good hydrogen evolution effect, and solve the effect of performance decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

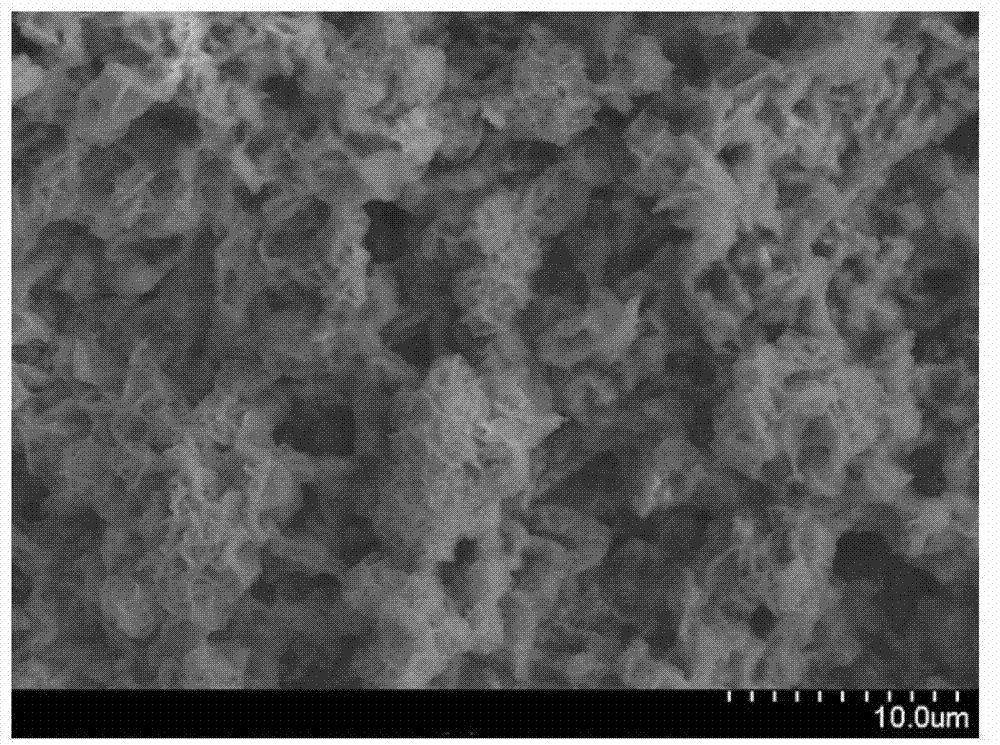

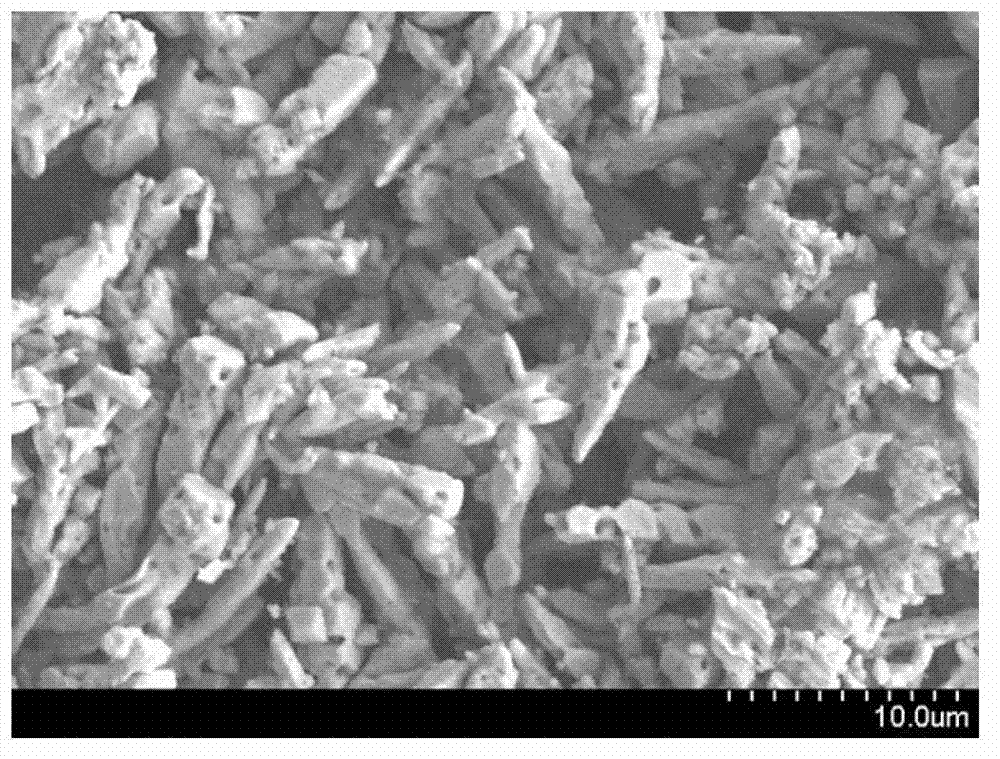

[0027] This example shows the method for electrochemically modifying the surface of the negative plate of a common lead-acid battery and the surface morphology of the electrode.

[0028] Select ordinary lead-acid battery negative plate (cooked plate) for surface modification. The specific implementation method is as follows: the polypyrrole is synthesized at 0.8V by the constant potential method, and the platinum electrode and the saturated calomel electrode (SCE) are respectively used as the counter electrode and the reference electrode. The concentration of pyrrole in the electrolyte is 0.15M, and sodium p-toluenesulfonate is used as a dopant with a concentration of 0.2M. Scanning electron micrograph of the negative plate modified by 60s polypyrrole compared with the ordinary negative plate without modification (see figure 1 and figure 2 ) shows that the surface of the negative plate before modification is lead sponge, and the structure is relatively sparse. After modifi...

Embodiment 2

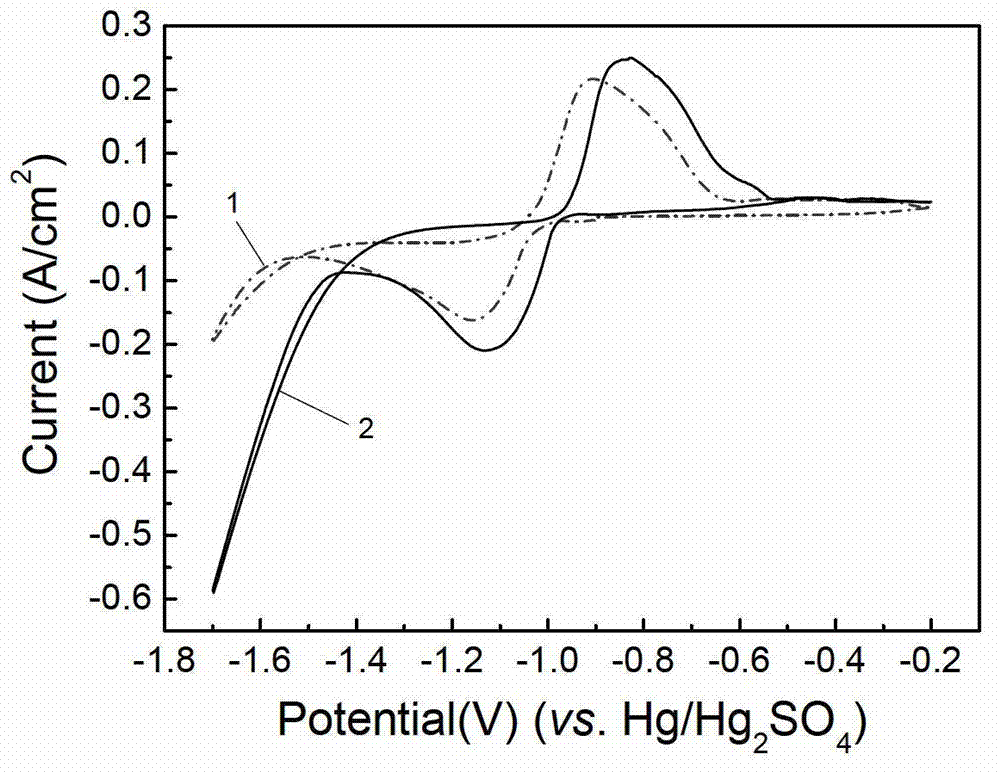

[0030] This example uses cyclic voltammetry to characterize the electrochemical properties of a new lead-acid battery negative electrode containing polypyrrole (0.5% graphite microflakes in the active material) obtained by electrochemical modification, and demonstrates the ability of polypyrrole film to inhibit hydrogen evolution Effect.

[0031] Research electrode manufacturing method for cyclic voltammetry performance test: a pure lead electrode with a diameter of 10mm, one end is welded with a copper wire, and the part immersed in the electrolyte is sealed with an insulating acid-resistant glue, and a drill is drilled on one side of the electrode plane. A circular hole with a diameter of 2.6mm, the depth of the lead surface from the insulating surface is 1mm, which is used to fill the active material (lead paste) under study, and the paste-coated electrode is made into a research electrode through curing, drying, chemical formation and other processes.

[0032] The preparat...

Embodiment 3

[0035] This example uses cyclic voltammetry to characterize the electrochemical properties of the lead-carbon battery negative electrode (containing 3.0% carbon black in the active material) obtained by the electrochemical modification method containing polypyrrole, and shows that the polypyrrole modified electrode inhibits the charging of the negative electrode. The effect of hydrogen evolution.

[0036] The same method as in Example 2 was used to fabricate and modify the research electrode. The difference is that 3.0% carbon black is added to the negative active material in the research electrode without adding graphite microflakes. The modified electrode and the unmodified electrode were tested for cyclic voltammetry performance, and the results were as follows: Figure 4 shown.

[0037]The results showed that the hydrogen evolution peak of the modified electrode around -1.7V was significantly lower, and the hydrogen evolution potential of the unmodified electrode was sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com