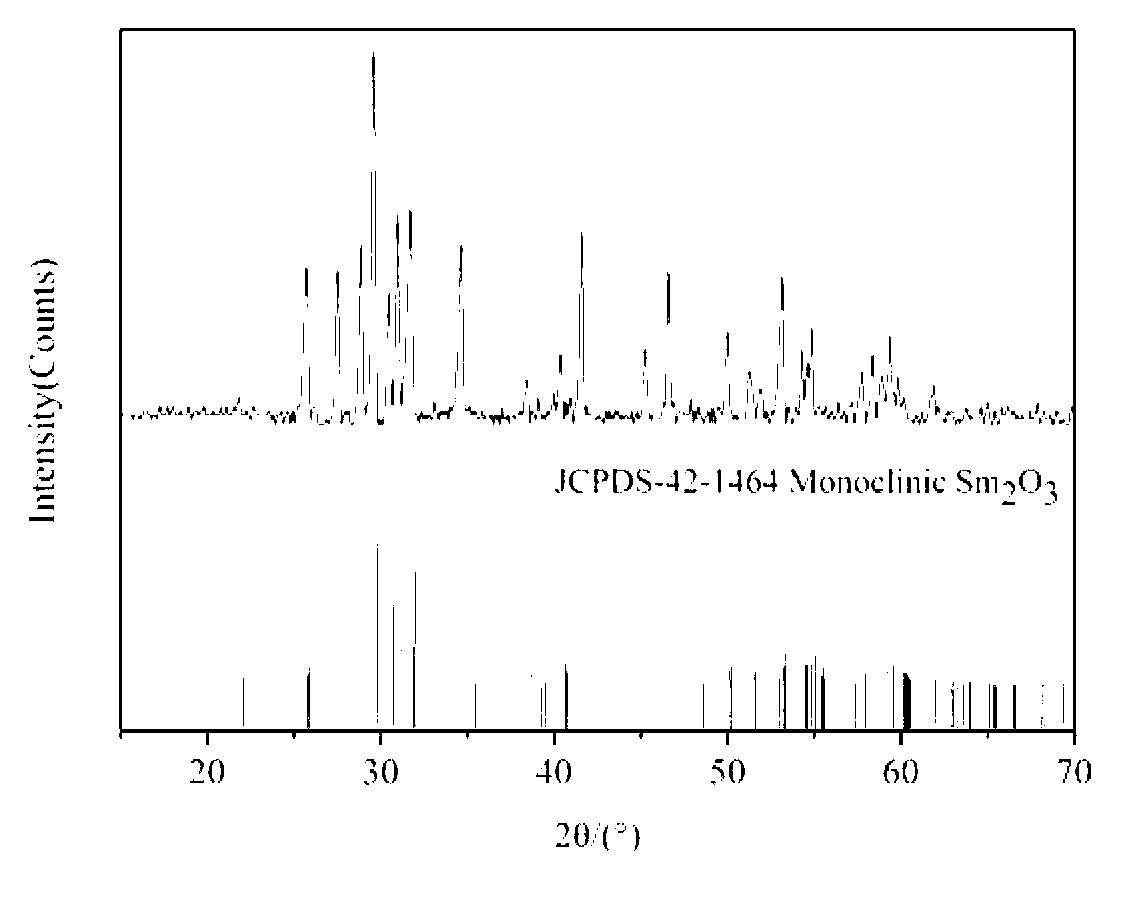

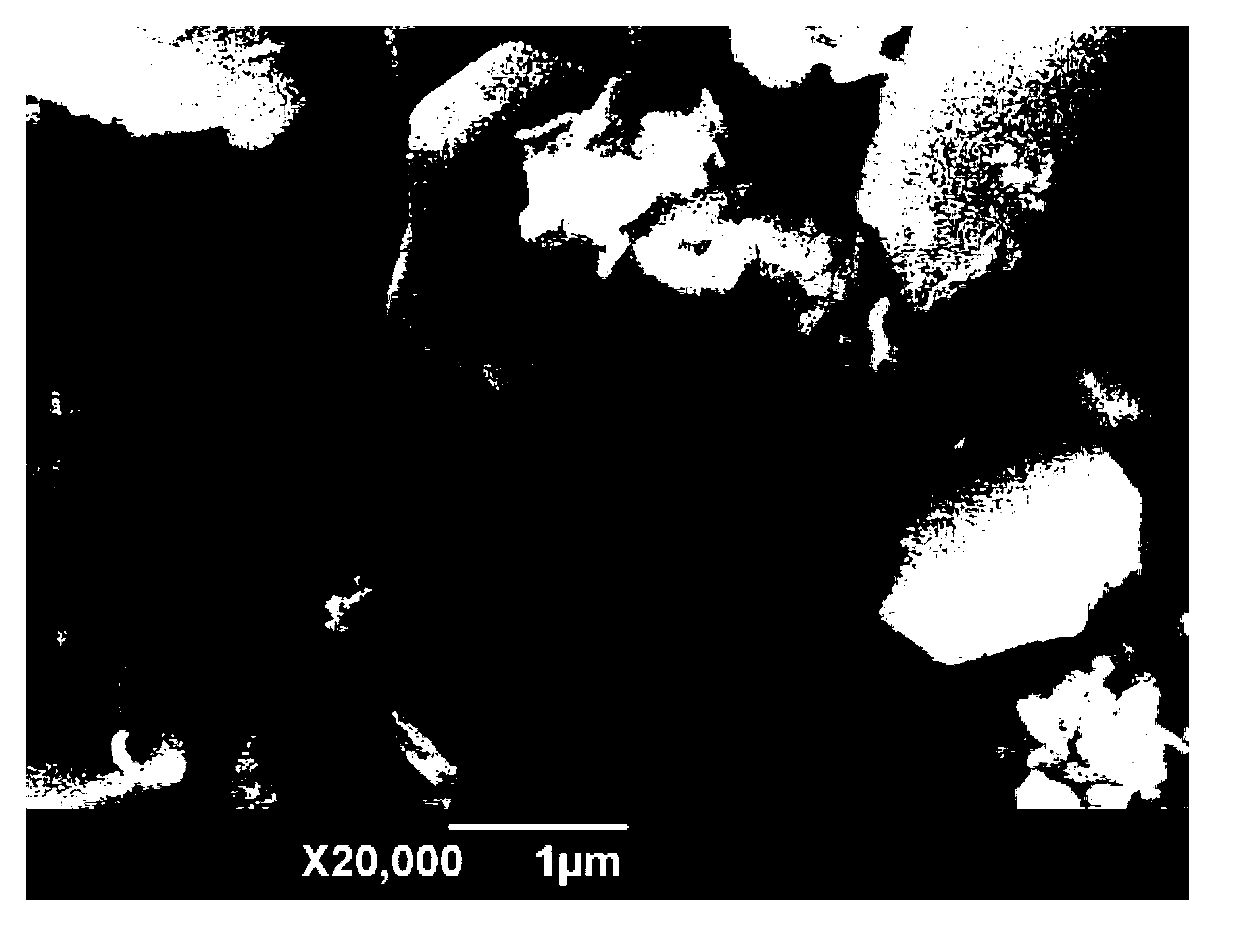

Method for preparing Sm2O3 semiconductor nanocrystals with hexagonal sheet structures

A hexagonal sheet-like semiconductor technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of easy powder agglomeration process cycle, low raw material utilization rate, easy powder agglomeration, etc., to reduce the phenomenon of agglomeration , avoid structural defects, and avoid the effect of introducing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1) The analytically pure SmCl 3 ·6H 2 O was added to isopropanol and stirred with a magnetic stirrer to prepare Sm 3+ Solution A with a concentration of 0.5mol / L;

[0021] 2) Heat and stir solution A at 45°C, adjust the pH value of solution A to 9 with NaOH solution with a concentration of 1mol / L, continue stirring for 1 hour to form a precursor solution, and then add hexadecyltri Methyl ammonium bromide (CTAB), the ratio of the amount of substance of its add-on and product theoretical output is n=0.5, confirms again that the pH value of precursor solution is 9;

[0022] 3) Pour the precursor solution into the hydrothermal kettle, the filling degree is controlled at 50%, then seal the hydrothermal kettle, put it into a DHG-9075A electric blast drying oven, and control the hydrothermal temperature to 120°C. The pressure is 8MPa, react for 48 hours, and naturally cool to room temperature after the reaction;

[0023] 4) Turn on the hydrothermal kettle, take out the pro...

Embodiment 2

[0025] 1) The analytically pure SmCl 3 ·6H 2 O was added to isopropanol and stirred with a magnetic stirrer to prepare Sm 3+ Solution A with a concentration of 0.2mol / L;

[0026] 2) Heat and stir solution A at 50°C, use NaOH solution with a concentration of 2mol / L to adjust the pH value of solution A to 10, continue stirring for 1.5 hours to form a precursor solution, and then add hexadecyltri Methyl ammonium bromide (CTAB), the ratio of the amount of substance of its add-on and product theoretical output is n=1; Confirm again that the pH value of precursor solution is 10;

[0027] 3) Pour the precursor solution into the hydrothermal kettle, the filling degree is controlled at 55%, then seal the hydrothermal kettle, put it into a DHG-9075A electric blast drying oven, and control the hydrothermal temperature to 150°C. The pressure is 15MPa, react for 60 hours, and naturally cool to room temperature after the reaction;

[0028] 4) Open the hydrothermal kettle, take out the p...

Embodiment 3

[0030] 1) The analytically pure SmCl 3·6H 2 O was added to isopropanol and stirred with a magnetic stirrer to prepare Sm 3+ Solution A with a concentration of 0.1mol / L;

[0031] 2) Heat and stir solution A at 48°C, adjust the pH value of solution A to 11 with NaOH solution with a concentration of 2mol / L, continue stirring for 2 hours to form a precursor solution, and then add hexadecyltri Methyl ammonium bromide (CTAB), the ratio of the amount of substance of its add-on and product theoretical output is n=2; Confirm again that the pH value of precursor solution is 11;

[0032] 3) Pour the precursor solution into the hydrothermal kettle, the filling degree is controlled at 50%, then seal the hydrothermal kettle, put it into the DHG-9075A type electric blast drying oven, control the hydrothermal temperature to 180°C, The pressure is 20MPa, react for 72 hours, and naturally cool to room temperature after the reaction;

[0033] 4) Open the hydrothermal kettle, take out the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com