Microwave dielectric ceramic and preparation method thereof

A microwave dielectric ceramic and a new technology, applied in the field of microwave dielectric ceramics, can solve the problems of difficult large-scale production, damage to the performance of ceramic materials, and density of volatile materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

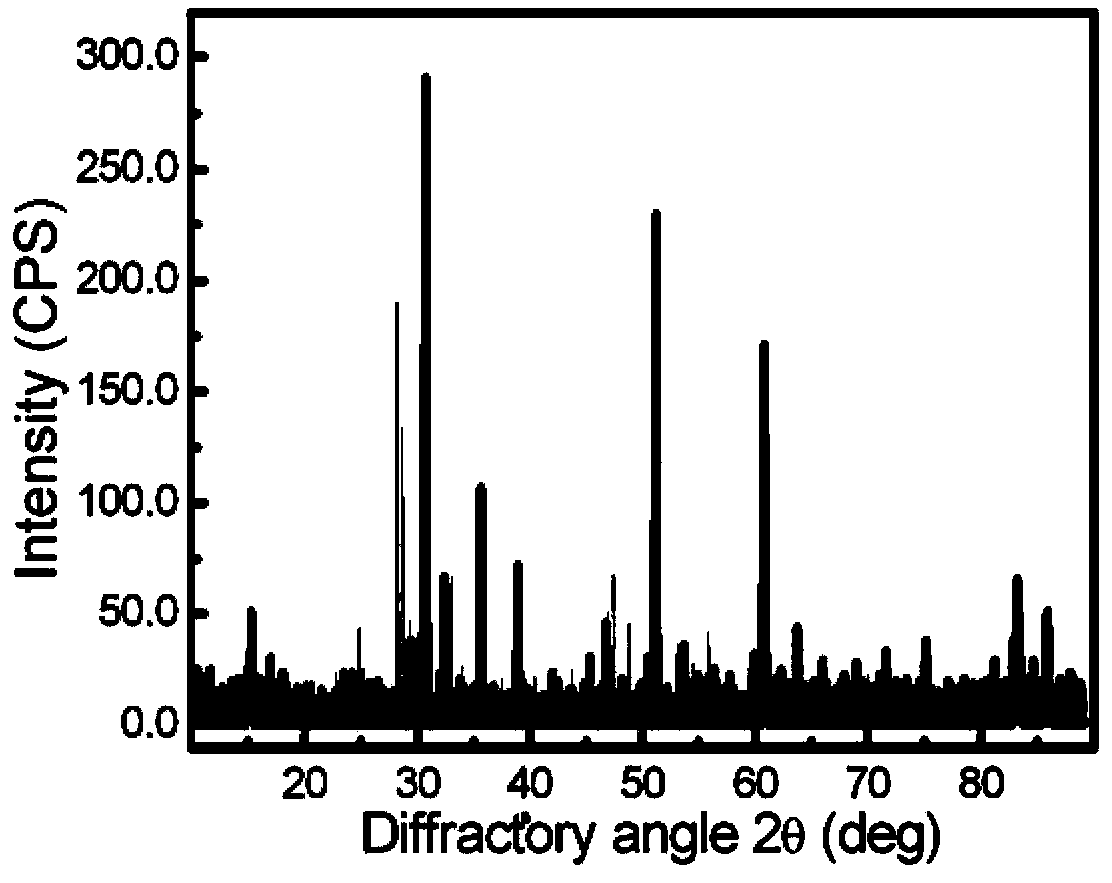

Embodiment 1

[0034] Weigh the raw materials according to the molecular formula of the formula: the molecular formula is K 0.5 Dy 4.5 Ti 4 o 15 , the molecular weight is 1182.3902, the mass of ingredients is 118.2390 g, and the molar number of ingredients is 0.10;

[0035] Weigh the required raw material K 2 CO 3 Mass is 3.490 g; Dy 2 o 3 Mass is 84.216 g, TiO 2 The amount is 36.227 g.

[0036] The preparation method is:

[0037] (1) Put the weighed raw materials into a ball mill jar and mill for 4-48 hours, then put them in a dry box at 80-180 o Tumble dry at C.

[0038] (2) The obtained mixed powder is pre-fired at high temperature to obtain superfine powder. It needs to be heated for 16 hours during pre-burning, and the required temperature is 1100 o C, keep warm for 4 hours.

[0039] (3) After grinding and sieving, add the prepared polyvinyl alcohol glue to the powder, the amount of polyvinyl alcohol added is 10% of the total mass of the raw material design; after pre-pressi...

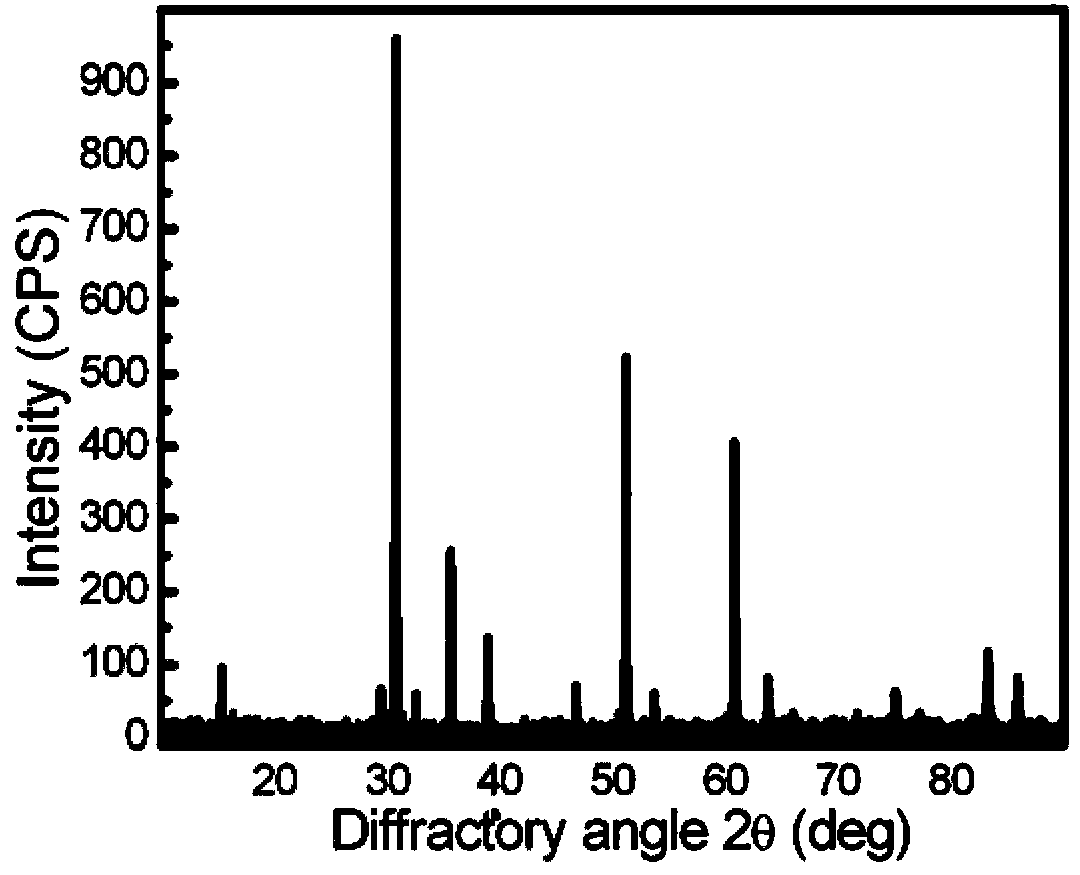

Embodiment 2

[0041] According to the general formula, the raw materials potassium carbonate, titanium dioxide and holmium oxide were weighed.

[0042] Molecular formula is K 0.5 Ho 4.5 Ti 4 o 15 , the molecular weight is 1193.19, the mass of ingredients is 119.319 g, and the molar number of ingredients is 0.10mol;

[0043] The preparation method is:

[0044] (1) Weigh the required raw material K 2 CO 3 Mass is 3.490 g; Ho 2 o 3 Mass is 85.061 g, TiO 2 The amount is 36.227 g.

[0045] (2) Put the weighed raw materials into a ball mill jar for ball milling for 48 hours, and then put them in a drying oven at 180 o Tumble dry at C.

[0046] (3) The obtained mixed powder is pre-fired at high temperature to obtain superfine powder. During pre-burning, the temperature needs to be raised for 20 hours, and the temperature is raised to the required temperature of 900 o After C, keep warm for 5 hours.

[0047] (4) After grinding and sieving, add the prepared polyvinyl alcohol glue to th...

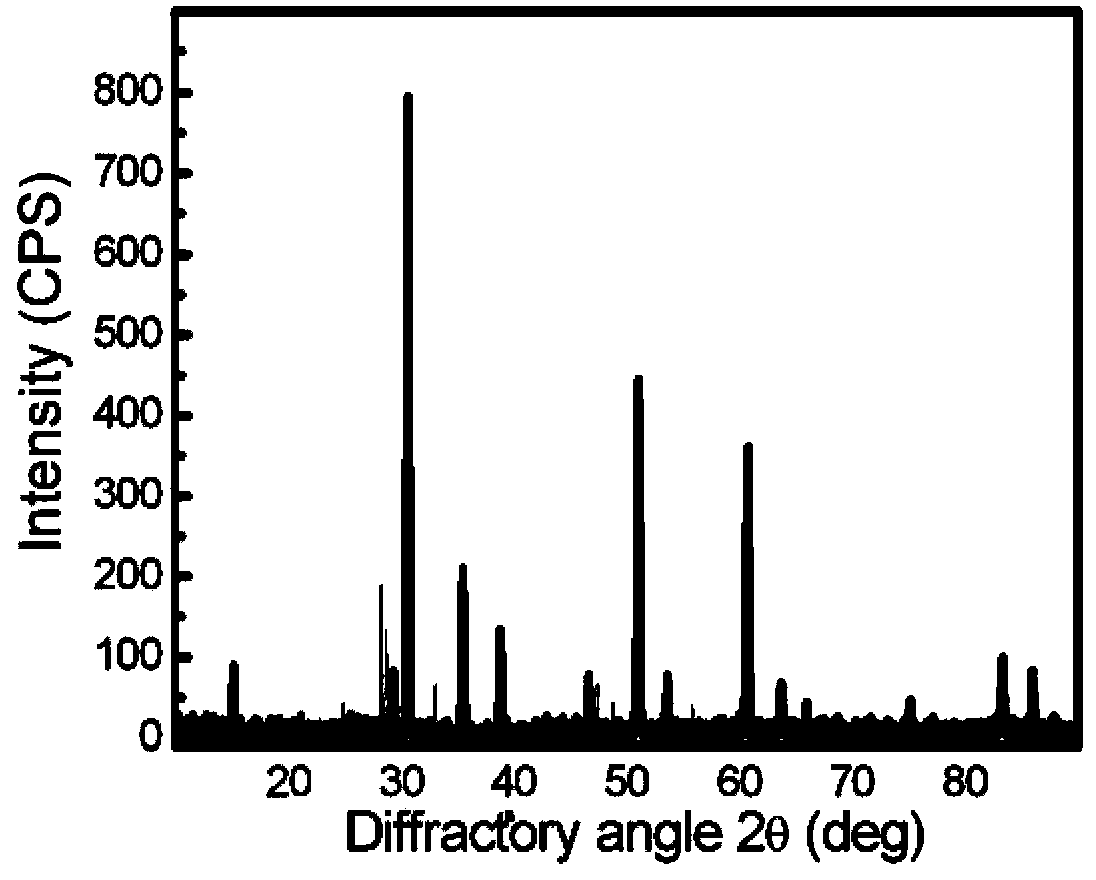

Embodiment 3

[0049] Weigh the raw materials potassium carbonate, titanium dioxide and erbium oxide according to the general formula.

[0050] Molecular formula is K 0.5 Er 4.5 Ti 4 o 15 , the molecular weight is 1203.8102, the mass of ingredients is 120.3810 g, and the molar number of ingredients is 0.10mol;

[0051] The preparation method is:

[0052] (1) Weigh the required raw material K 2 CO 3 Mass is 3.490 g; Er 2 o 3 Mass is 86.076 g, TiO 2 The amount is 36.227 g.

[0053] (2) Put the weighed raw materials into a ball mill jar and mill them for 4 hours.

[0054] (3) The raw materials after ball milling are placed in a drying oven at 180 o C drying, after drying, pulverization, pre-calcination, grinding, and sieving to obtain powder materials; the obtained mixed powder is pre-calcined at high temperature to obtain ultra-fine powder materials. During pre-calcination, the temperature needs to be raised for 12 hours, and the temperature is raised to 1200 °C. o After C, keep wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com