Water-based latent curing agent for epoxy resin and application of water-based latent curing agent

An epoxy resin curing and latent technology, which is applied in fiber processing, textiles and papermaking, carbon fiber, etc., can solve the problems of negative impact on the interface of composite materials, affecting the bonding of fiber and matrix, and the reduction of carbon fiber clustering, so as to improve the fiber and Substrate bonding, shortening reaction time, increasing the effect of connection points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

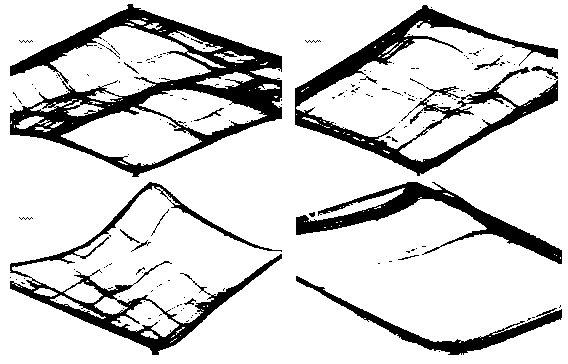

Image

Examples

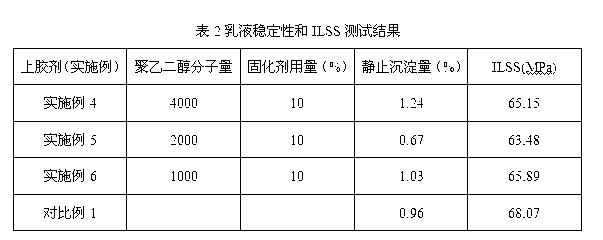

Embodiment 1

[0021] Preparation of Polymers of Ethylene Glycol Bisglycidyl Ether and Polyethylene Glycol

[0022] In a four-necked flask with condensed water, put 10g of polyethylene glycol 4000 and 0.96g of ethylene glycol bisglycidyl ether, then add 20ml of acetone as a solvent, heat and stir at 40°C to mix the materials evenly. Keep the temperature constant and add 0.42g of boron trifluoride etherate complex and 9.58g of solvent acetone to form a boron trifluoride catalyst solution with a concentration of 2%wt. Add dropwise for 1 hour. After the dropwise addition, keep the temperature constant and continue stirring React for 1h, terminate the reaction to obtain a polymer, wherein the molar ratio of ethylene glycol bisglycidyl ether to polyethylene glycol is 2.2:1;

[0023] Preparation of water-based latent epoxy resin curing agent

[0024] Primary amine groups according to DDS vs. step by step The mol ratio that makes the epoxy group of polymkeric substance is 2:1, takes by weigh...

Embodiment 2

[0028] Preparation of Polymers of Ethylene Glycol Bisglycidyl Ether and Polyethylene Glycol

[0029] In a four-necked flask with condensed water, put 5g of polyethylene glycol 2000 and 0.96g of ethylene glycol bisglycidyl ether, and then add about 20ml of acetone as a solvent, and heat and stir at 40°C to mix the materials evenly. Keeping the temperature constant, add 0.21g boron trifluoride diethyl ether complex and 4.79g solvent acetone to form a concentration of 2%wt boron trifluoride catalyst solution. Others are the same as in Example 1, wherein ethylene glycol bisglycidyl ether and poly The molar ratio of ethylene glycol is 2.2:1;

[0030] Preparation of water-based latent epoxy resin curing agent

[0031] Primary amine groups according to DDS vs. step by step The mol ratio that makes the epoxy group of polymkeric substance is 2:1, takes by weighing 1.22gDDS, and drops into step The prepared polymer was stirred and heated at 130° C. for 3 hours to obtain a water...

Embodiment 3

[0035] Preparation of Polymers of Ethylene Glycol Bisglycidyl Ether and Polyethylene Glycol

[0036]Put 2.5g of polyethylene glycol 1000 and 0.96g of ethylene glycol bisglycidyl ether into a four-necked flask with condensed water, then add about 20ml of acetone as a solvent, heat and stir at 40°C to mix the materials evenly. Keeping the temperature constant, add 0.10g boron trifluoride etherate complex and 2.40g solvent acetone to form a concentration of 2%wt boron trifluoride catalyst solution. Others are the same as in Example 1, wherein ethylene glycol bisglycidyl ether and poly The molar ratio of ethylene glycol is 2.2:1;

[0037] Preparation of water-based latent epoxy resin curing agent

[0038] Primary amine groups according to DDS vs. step by step The mol ratio that makes the epoxy group of polymkeric substance is 2:1, takes by weighing 1.22gDDS, and drops into step The prepared polymer was stirred and heated at 130° C. for 3 hours to obtain a water-based late...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com