Preparation method of ZnO (zinc oxide) nanometer-micrometer rod with parallelogram cross section

A zinc oxide nanometer and parallelogram technology, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problem of no breakthrough in the form of microcavities, and achieve controllable shape and size, controllable size, and good product repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) A single crystal silicon wafer (20 mm × 15 mm) was ultrasonically cleaned with deionized water and absolute ethanol for 5 min, and then an Au layer with a thickness of about 10 nm was deposited on the surface of the substrate as a catalyst by thermal evaporation deposition technology. Take a quartz boat with a size of 20mm×15mm×10mm in the boat and ultrasonicate it with deionized water for 5 minutes, and dry it for later use.

[0025] (2) Zn powder Sb 2 o 3 Powder and carbon powder (purity requirements >99.9%) were prepared according to the molar ratio of 160:30:2, placed in an agate mortar and mixed evenly, as the reaction raw materials. The total weight of the ingredients is about 0.8 g.

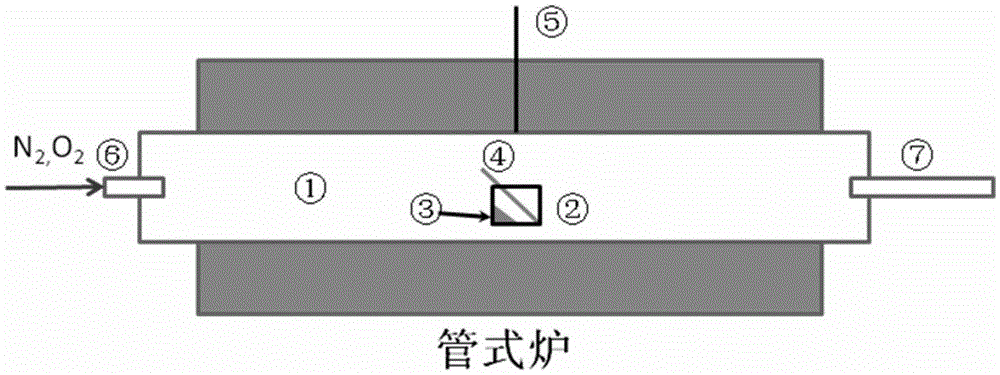

[0026] (3) Put the reaction raw materials into the quartz boat, and tilt the raw materials to one corner, then place the Au side of the silicon wafer downwards, and buckle it obliquely above the raw materials, and the upper surface of the raw materials is 3~8mm away from the s...

Embodiment 2

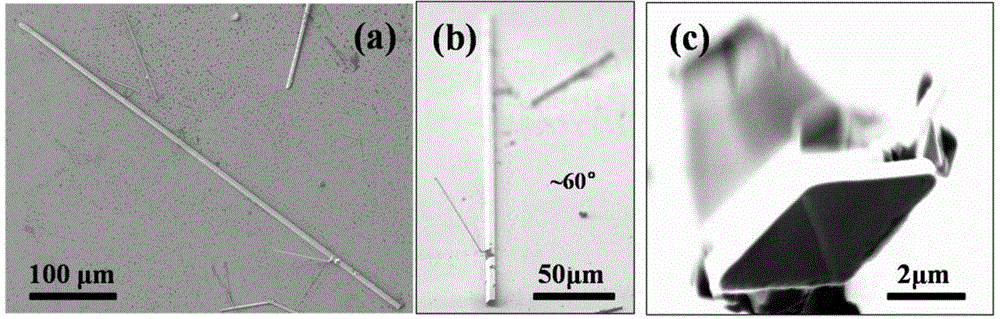

[0030] This embodiment mainly investigates the effects of Zn source, raw material ratio, deposition substrate material, reaction temperature, reaction time and gas ratio on the morphology and size of the obtained oxidized nano / micro rods during the preparation of parallelogram zinc oxide nano / micro rods . The specific experimental process is the same as in Example 1, the difference is that the Zn source is changed to ZnO, the raw material ratio, the deposition substrate material, the reaction temperature, the reaction time and the gas ratio. The specific experimental parameters are shown in Table 1. It can be seen from the experimental results that changing the zinc source to ZnO has no effect on the morphology of the samples. Change the raw material ratio in Zn:C:Sb 2 o 3 When the molar ratio is 160:30:2~4, the yield is high and the quality is good. The samples outside this ratio will have other shapes, but there are still a large number of diamond-shaped ZnO nano / microrod...

Embodiment 3

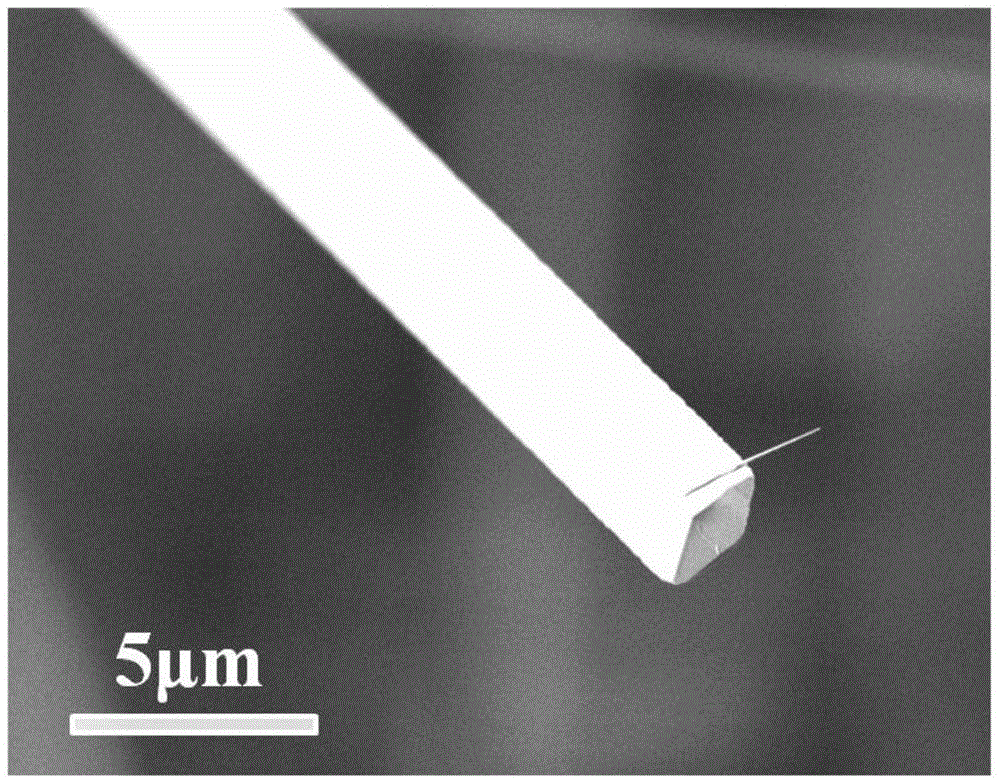

[0032] This example mainly examines whether the parallelogram zinc oxide nano / microrods of Example 1 can be used in optical microcavities

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com