Preparation method of high-temperature resistant silicon carbide aerogel heat-insulation composite material

A composite material and aerogel technology, which is applied in the field of preparation of high-temperature-resistant silicon carbide airgel thermal insulation composite materials, can solve unsatisfactory problems, and achieve the effects of low cost, easy-to-obtain raw materials, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

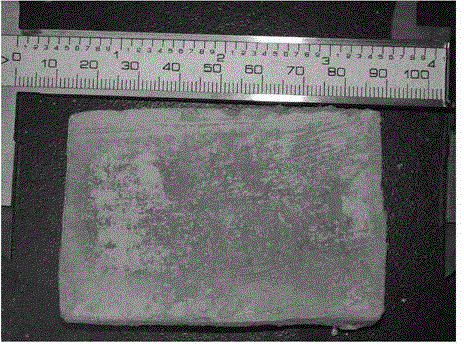

Image

Examples

example 1

[0016] Mix resorcinol, formaldehyde, 3-aminopropyltriethoxysilane, water, and ethanol in a molar ratio of 1:2:1.5:3:17 to form a carbon-silicon mixed sol; pour the mixed sol into the In the mold with pretreated aluminum silicate fiber cotton, keep the sol liquid level just submerged fiber cotton, after sealing, carry out sol-gel reaction at 25°C for 4 hours to obtain fiber-reinforced carbon-silicon composite gel; After taking out the carbon-silicon composite gel, dry it in a 50°C oven under normal pressure for 12 hours to obtain a fiber-reinforced carbon-silicon composite aerogel; place the fiber-reinforced carbon-silicon composite aerogel in a tube furnace, Next, heat up to 1500°C with a heating rate of 1°C / min, keep it warm for 5 hours, and obtain a silicon carbide product containing residual carbon after being cooled to room temperature; Calcined in the atmosphere for 2 hours to obtain a fiber-reinforced high-temperature-resistant silicon carbide airgel heat-insulating comp...

example 2

[0018] Mix resorcinol, formaldehyde, 3-aminopropyltriethoxysilane, tetraethyl orthosilicate, water, and ethanol in a molar ratio of 1:2:1.8:0.2:4:34 to make carbon-silicon Mixed sol: Pour the mixed sol into a mold equipped with pretreated aluminum silicate fiber cotton, keep the sol liquid level just submerged in the fiber cotton, and perform sol-gel reaction at 40°C for 8 hours after sealing to obtain fiber reinforcement Carbon-silicon composite gel; take out the fiber-reinforced carbon-silicon composite gel and dry it in a 60°C oven under normal pressure for 12 hours to obtain fiber-reinforced carbon-silicon composite aerogel; place the fiber-reinforced carbon-silicon composite aerogel In a tube furnace, under the protection of argon, the temperature was raised to 1550°C at a heating rate of 1°C / min, kept for 4 hours, and a silicon carbide product containing residual carbon was obtained after cooling to room temperature; the fiber containing residual carbon was The reinforce...

example 3

[0021] Mix resorcinol, formaldehyde, 3-aminopropyltriethoxysilane, tetraethylorthosilicate, water, and ethanol in a molar ratio of 1:2:1:1:4:69 to make carbon-silicon Mixed sol; pour the mixed sol into a mold with pretreated aluminum silicate fiber cotton, keep the sol liquid level just submerged in the fiber cotton, and perform sol-gel reaction at 60°C for 12 hours after sealing to obtain fiber reinforcement Carbon-silicon composite gel; take out the fiber-reinforced carbon-silicon composite gel and dry it in a 70°C oven under normal pressure for 48 hours to obtain fiber-reinforced carbon-silicon composite aerogel; place the fiber-reinforced carbon-silicon composite aerogel In a tube furnace, under the protection of argon, the temperature was raised to 1600°C at a heating rate of 2°C / min, kept for 3 hours, and a silicon carbide product containing residual carbon was obtained after cooling to room temperature; the fiber containing residual carbon was The reinforced airgel samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com