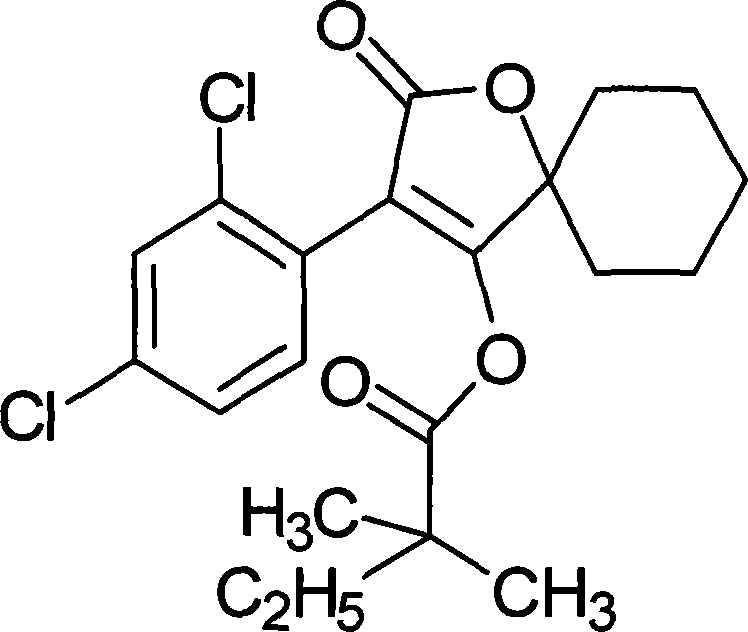

Emulsible granule containing spirodiclofen composition and preparation method thereof

A composition and technology of spirodiclofen, applied in the field of emulsifiable granules, to achieve the effects of good wettability, safe use, easy packaging and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

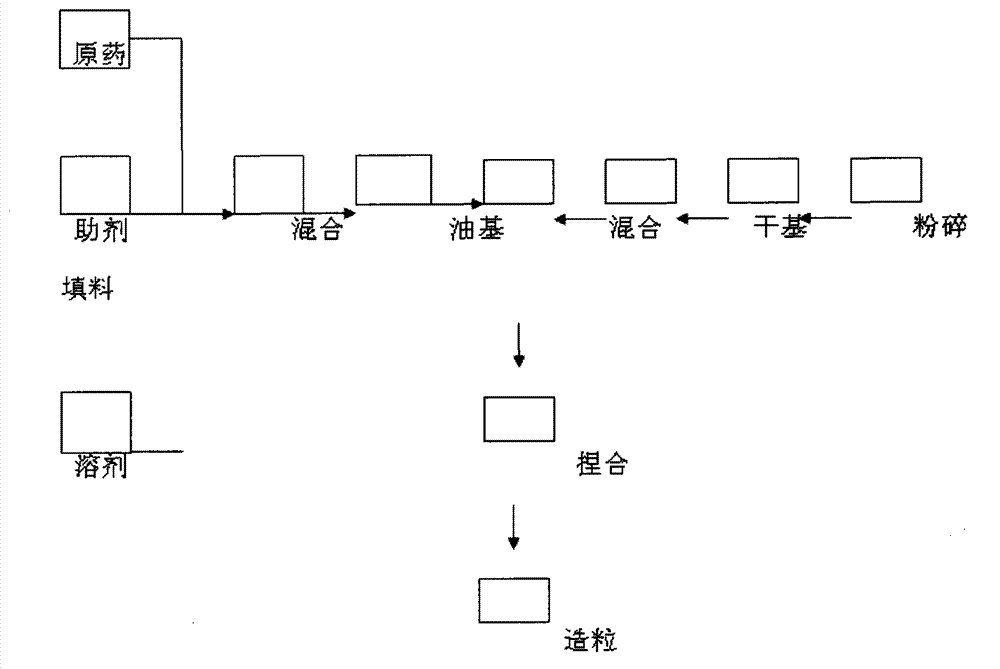

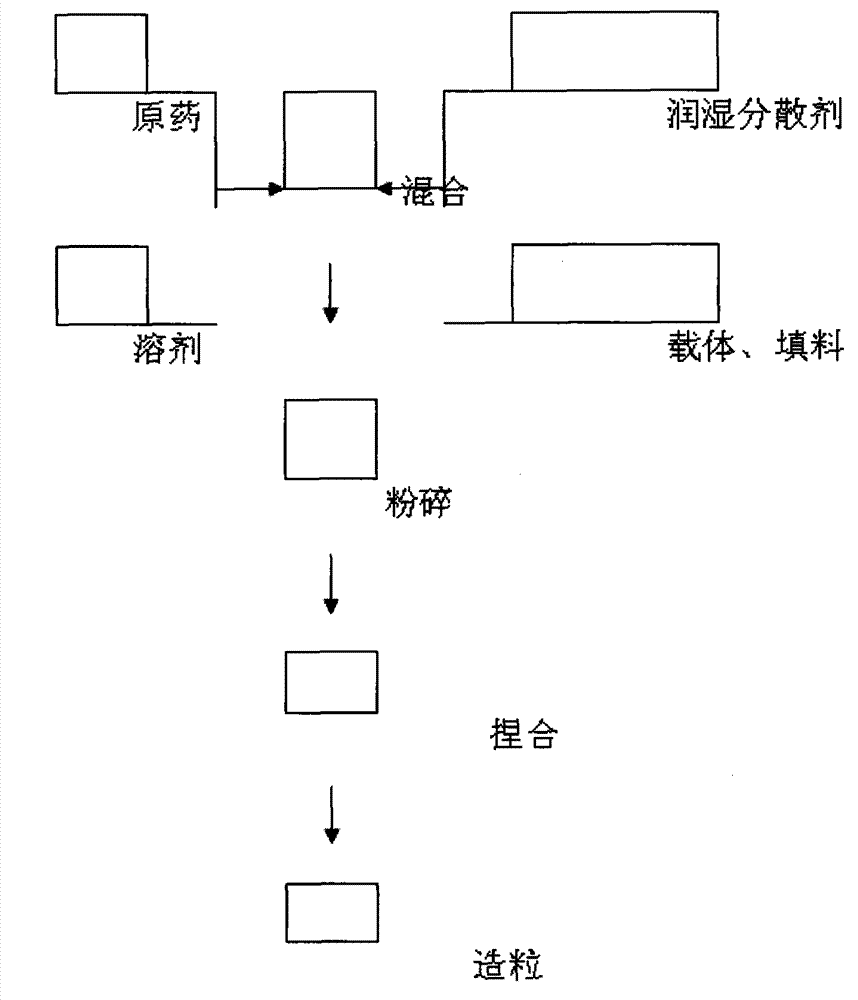

Method used

Image

Examples

Embodiment 1

[0021] The weight ratio of components is:

[0022]

[0023] First, 2 parts of sodium naphthalenesulfonate formaldehyde condensate, 1.5 parts of sodium lauryl sulfate, 3 parts of sodium salt of alkylnaphthalenesulfonic acid condensation polymer, 3 parts of alkylphenol polyoxyethylene ether formaldehyde condensate sulfate, Mix 20 parts of white carbon black and 50.5 parts of diatomaceous earth in a beaker, then add 5 parts of spirodiclofen, 5 parts of tebufenfen, 4 parts of agricultural milk 0201B, A mixture consisting of 3 parts of d-limonene and 3 parts of diethylene glycol dimethyl ether, mixed evenly, and pulverized by a jet mill to make the particle size reach 98% through 45 μm, and finally, add a certain amount of 2% ethanol aqueous solution Put it into the crushed material, knead and scraper granulate to obtain 10% spirodiclofen·tebufenpyrad emulsifiable granules.

Embodiment 2

[0025] The weight ratio of components is:

[0026]

[0027]

[0028] First, 1 part of carboxymethyl cellulose, 8 parts of bentonite, 1 part of sodium dodecylbenzenesulfonate, 3 parts of N-methyl-fatty acyl-sodium taurine, and 3 parts of alkylnaphthalenesulfonic acid polycondensate Sodium salt and 49 parts of activated clay were mixed in a beaker, and then at normal temperature and pressure, 7.5 parts of spirodiclofen, 7.5 parts of tebufenfen, 2 parts of castor oil polyoxyethylene ether, 2 parts of polyoxyethylene ether were added while stirring. A mixture consisting of 1 part of phenylethylphenol polyoxyethylene polyoxypropylene ether, 6 parts of Nongru 0201B, 5 parts of N-methylpyrrolidone, and 5 parts of xylene, mixed evenly, and pulverized by a jet mill to make the particle size reach 98 % pass through 45 μm, and finally, add a certain amount of distilled water to the above pulverized material, knead and scraper granulate to obtain 15% spirodiclofen·tebufenpyrad emuls...

Embodiment 3

[0030] The weight ratio of components is:

[0031]

[0032]

[0033] First, mix 20 parts of white carbon black and 36.5 parts of kaolin, and grind them through a jet mill to make the particle size reach 98% through 45 μm, and then add 10 parts of spirodiclofen while stirring under normal temperature and pressure conditions. , 10 parts of tebufenpyrad, 3 parts of sodium oleic acid methyl amino ethyl sulfonate, 5 parts of aralkylphenol polyoxyethylene ether phosphate, 5 parts of tristyrylphenol polyoxyethylene (n 20 ) ether phosphorylated triethanolamine salt, 1.5 parts of alkylphenol formaldehyde resin polyoxyethylene ether, 3 parts of d-limonene, 5 parts of N-methylpyrrolidone, and 1 part of polyethylene glycol 400. Mix evenly, and finally , adding a certain amount of distilled water to the crushed material, kneading and scraper granulation; 20% spirodiclofen·tebufenfen emulsifiable granules can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com