Ultrahigh nitrogen austenite phase diffusion hardening covering layer for pump shafts of nuclear grade pumps

A diffusion hardening and coating technology, applied in solid diffusion coating, coating, metal material coating technology and other directions, can solve the problems of human body harm, low hardness of electroplated chromium layer, non-dense structure, etc., to achieve wear resistance and corrosion resistance. The effect of improved performance, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

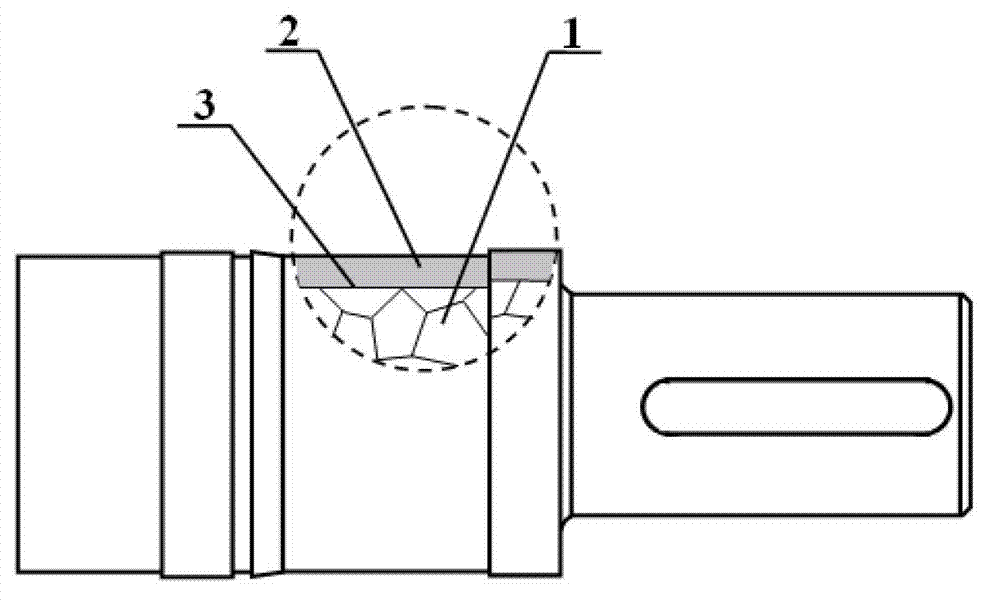

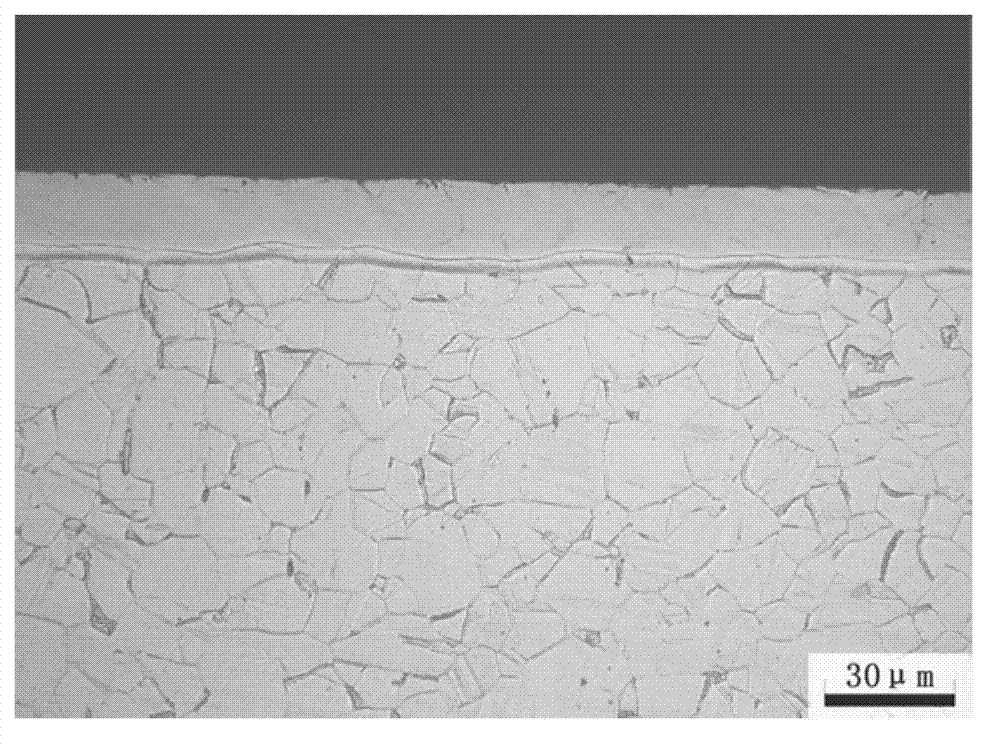

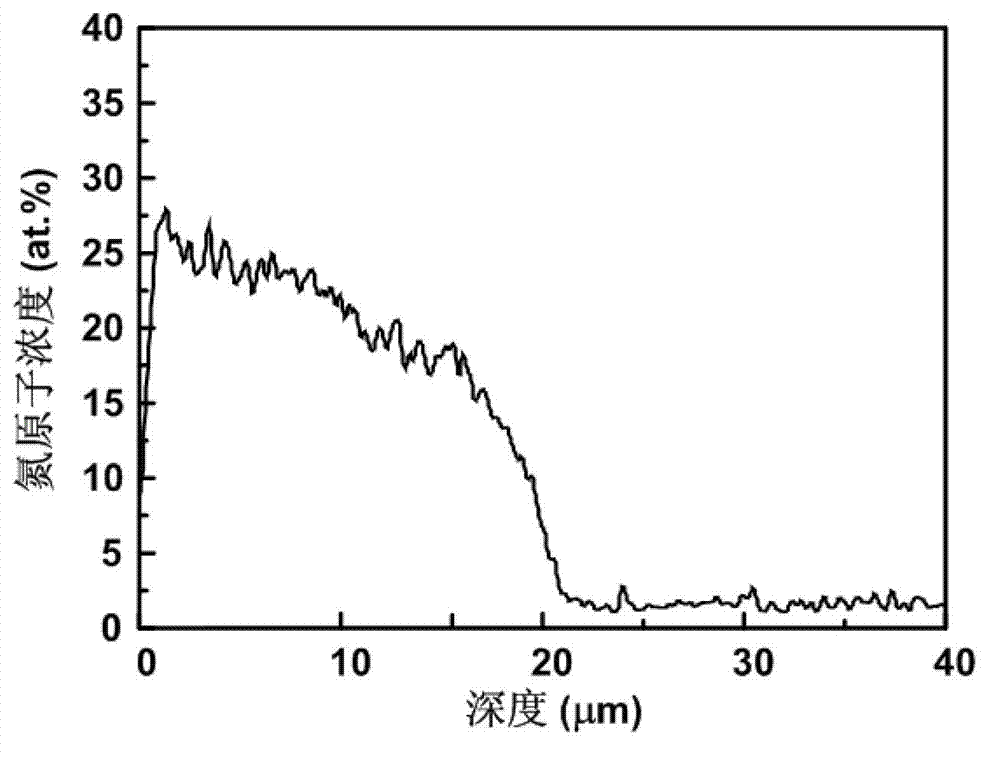

[0028] Using plasma source nitriding technology to treat AISI 304 austenitic stainless steel nuclear main pump shaft, the specific process parameters and steps are as follows:

[0029] Clean the surface of the pump shaft of the nuclear main pump, and use an anti-seepage layer to protect the non-hardened surface. After exposing the surface that needs diffusion hardening, place the pump shaft on the workpiece table of the plasma source nitriding device, close the vacuum chamber, and evacuate to Background vacuum 1.5×10 -1 Pa. The working gas ammonia was introduced, the working pressure was maintained at 300 Pa, and a pulsed negative bias of 800 V was applied on the metal screen with a frequency of 1 kHz to generate DC pulsed plasma. The nitriding temperature is 450 °C, and the temperature is kept for 6 hours. After the treatment, the system is closed, cooled to room temperature with the furnace, the vacuum chamber is opened, and the pump shaft of the nuclear main pump is taken...

Embodiment 2

[0031] The main feed pump shaft of 1Cr18Ni9Ti austenitic stainless steel is treated by plasma-based low-energy nitrogen ion implantation technology. The specific process parameters and steps are as follows:

[0032] Clean the surface of the pump shaft of the main feed water pump, place it on the workpiece table after partial anti-seepage protection, close the vacuum chamber, and evacuate to a background vacuum of 1.5×10 -3 Pa, microwave power 1.5 kW, to generate electron cyclotron resonance (ECR) microwave plasma, through the working gas nitrogen, the working pressure is maintained at 5×10 -2 Pa, workpiece pulse bias voltage -2.0 kV, nitriding temperature is 400 °C, nitrogen ion beam current density is 0.6 mA / cm 2 , after 4 hours of treatment, shut down the system, cool down to room temperature with the furnace, open the vacuum chamber, and take out the pump shaft. After testing, the pump shaft of the main feed pump treated by plasma-based low-energy nitrogen ion implantati...

Embodiment 3

[0034] The pump shaft of the waste liquid delivery pump of AISI 304 austenitic stainless steel is treated by DC pulsed plasma-based low-energy ion implantation. The specific process parameters and steps are as follows:

[0035] Clean the surface of the pump shaft of the waste liquid delivery pump, place it on the workpiece table after partial anti-seepage protection, close the vacuum chamber, and evacuate to 5×10 -3 Pa, 700 V pulsed negative bias voltage is applied on the metal screen, the frequency is 1 kHz, the duty ratio is 1:5, DC pulsed plasma is generated, the workpiece bias voltage is -2.0 kV, the duty ratio is 1:5, and 25% of the working gas is passed through N 2 +75%H 2 , the working air pressure is maintained at 5×10 -2 Pa, nitriding temperature is 420 ° C, heat preservation for 8 hours, close the system, cool to room temperature with the furnace, open the vacuum chamber, and take out the pump shaft. After testing, the ultra-high nitrogen austenite phase diffusi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com