Low-cost low-pollution gallium nitride nano-wire preparation generation method

A gallium nitride nanowire and low-pollution technology, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve complex and expensive system equipment, unfavorable large-scale production, reactants or by-products Harmful to the human body or the environment, etc., to achieve the effect of simple equipment and excellent field emission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) The GaN powder is mixed with glue, ground, passed through an 80-mesh sieve, pressed into tablets, calcined at 560°C for 2 hours, and fired into a powder target. The preparation of powder targets in the prior art is a mature technology, and a slight change in the above parameters is also necessary for

[0022] Product performance is basically unaffected.

[0023] (2) Deposit the cleaned and dried silicon wafer in a SBC-12 small ion sputtering apparatus for 30s to obtain a substrate with a gold film with a thickness of about 10nm on the surface.

[0024] (3) The GaN powder target and substrate prepared by the above method, using the plasma-assisted hot wire chemical vapor deposition method: at a pressure of 1500Pa, a substrate temperature of 900°C, a bias current of 120mA, and a nitrogen flow rate of 40cm 3 / min, the hydrogen flow rate is 10 cm 3 / min, the deposition time is 5min, and GaN nanometers are obtained.

Embodiment 2

[0026] (1) The GaN powder is mixed with glue, ground, passed through an 80-mesh sieve, pressed into tablets, calcined at 560°C for 2 hours, and fired into a powder target.

[0027] (2) Deposit the cleaned and dried silicon wafer in a SBC-12 small ion sputtering apparatus for 30s to obtain a substrate with a gold film with a thickness of about 10nm on the surface.

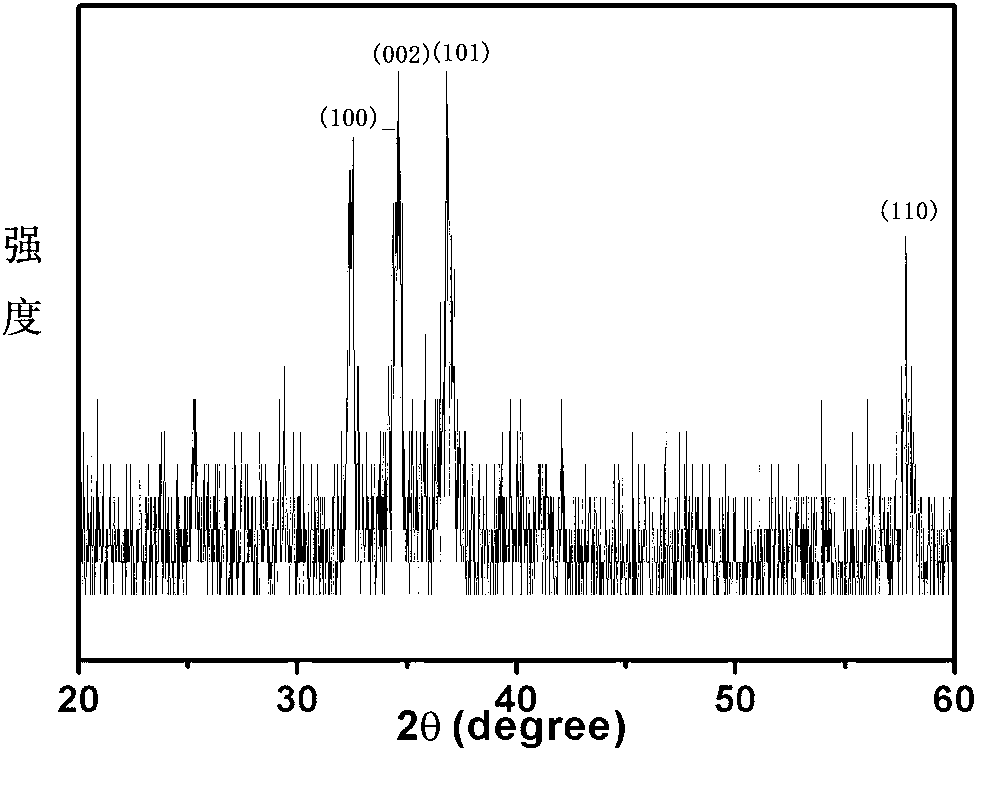

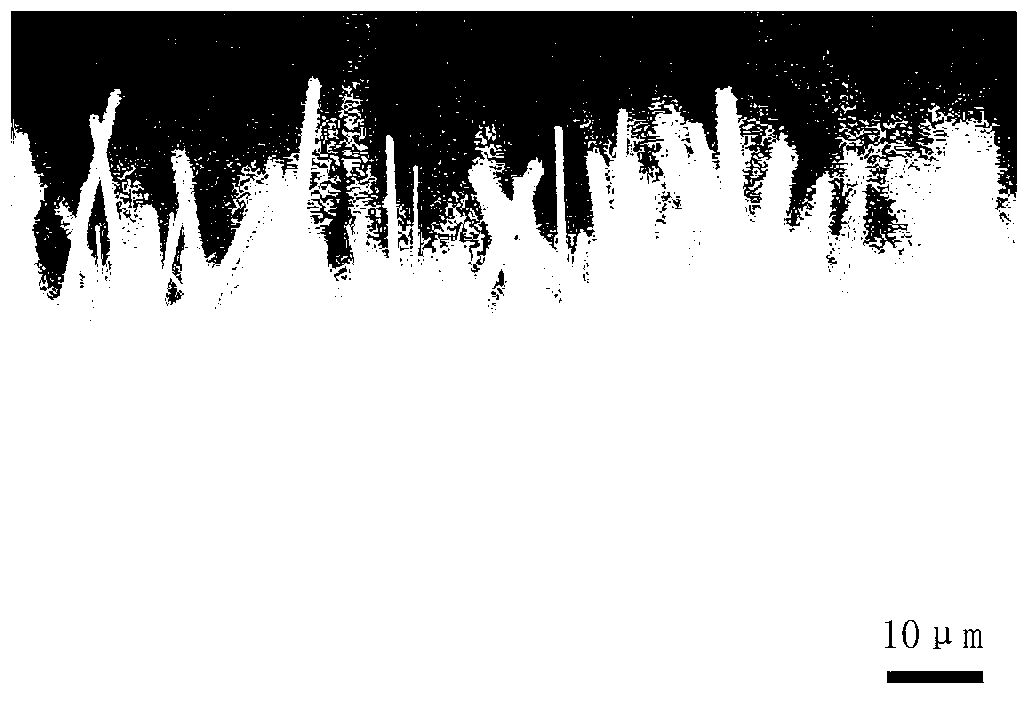

[0028] (3) The GaN powder target and substrate prepared by the above method, using the plasma-assisted hot wire chemical vapor deposition method: at a pressure of 1500Pa, a substrate temperature of 900°C, a bias current of 120mA, and a nitrogen flow rate of 40cm 3 / min, the hydrogen flow rate is 10 cm 3 / min, the deposition time is 20min, and GaN nanowires are obtained, and its XRD pattern is shown in figure 1 , and its SEM spectrum is shown in figure 2 , see its Raman spectrum Figure 4 , and its field emission current density spectrum is shown in Figure 6 .

Embodiment 3

[0030] (1) The GaN powder is mixed with glue, ground, passed through an 80-mesh sieve, pressed into tablets, calcined at 560°C for 2 hours, and fired into a powder target.

[0031] (2) Deposit the cleaned and dried silicon wafer in a SBC-12 small ion sputtering apparatus for 30s to obtain a substrate with a gold film with a thickness of about 10nm on the surface.

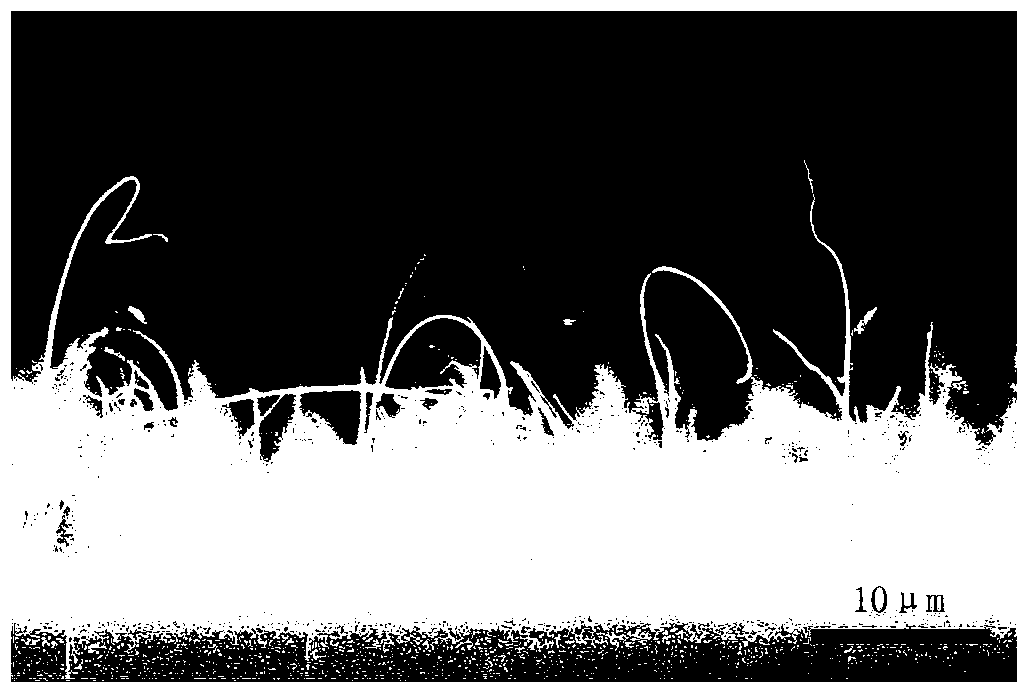

[0032] (3) The GaN powder target and substrate prepared by the above method, using the plasma-assisted hot wire chemical vapor deposition method: at a pressure of 1500Pa, a substrate temperature of 900°C, a bias current of 120mA, and a nitrogen flow rate of 40 cm 3 / min, the hydrogen flow rate is 10 cm 3 / min, the deposition time is 30min, and GaN nanowires are obtained, and its SEM diagram is shown in image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com