Esterification modification method for wood fiber biomasses

A technology for lignocellulosic and esterification modification, applied in the field of esterification modification of lignocellulosic biomass, can solve the problems of uneven and insufficient modification, complicated operation process, difficult solvent recovery, etc. Extensive, simple and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

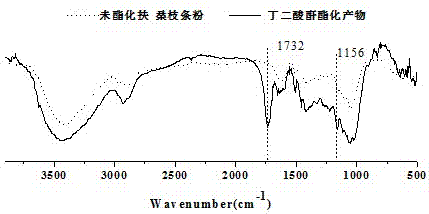

Embodiment 1

[0035] A method for esterification modification of lignocellulosic biomass, the specific steps are:

[0036] (1) Take hibiscus branches as raw materials, peel them, dry them, crush them mechanically, and dry them.

[0037] (2) A planetary ball mill is used to perform ball milling pretreatment on the raw materials, and the ball milling time is 15 hours. The material of the ball mill is agate, the capacity is 250mL, the amount of raw materials added is 7.2g, and the number of large, medium and small balls is 5, 30 and 45 respectively. The speed of ball milling is 580r / min, and there is no time interval between forward and reverse rotation; alternately every 90min.

[0038] (3) Add succinic anhydride to the ball-milled raw material, the ratio of raw material to succinic anhydride is 3:1 (w / w). Ball milling again, the material of the ball milling tank is zirconia, the capacity is 100mL, the number of large, medium and small balls is 0, 40, 60 respectively, the mass ratio of the ...

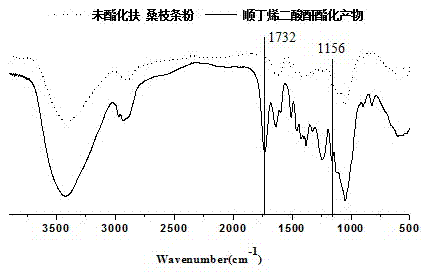

Embodiment 2

[0042] A method for esterification modification of lignocellulosic biomass, the specific steps are:

[0043] (1) Take hibiscus branches as raw materials, peel them, dry them, crush them mechanically, and dry them.

[0044] (2) A planetary ball mill is used to perform ball milling pretreatment on the raw materials, and the ball milling time is 15 hours. The material of the ball mill is agate, the capacity is 250mL, the amount of raw materials added is 7.2g, and the number of large, medium and small balls is 5, 30 and 45 respectively. The speed of ball milling is 580r / min, and there is no time interval between forward and reverse rotation; alternately every 90min.

[0045] (3) Add maleic anhydride to the ball-milled raw material, the ratio of raw material to maleic anhydride is 3:1 (w / w). Ball milling again, the material of the ball milling tank is zirconia, the capacity is 100mL, the number of large, medium and small balls is 0, 40, 60 respectively, the mass ratio of the amou...

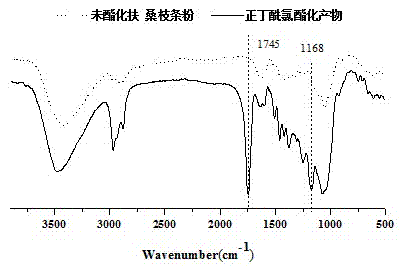

Embodiment 3

[0049] A method for esterification modification of lignocellulosic biomass, the specific steps are:

[0050] (1) Using hibiscus branches as raw materials, carry out peeling , dried, and mechanically crushed and dried.

[0051] (2) A planetary ball mill is used to perform ball milling pretreatment on the raw materials, and the ball milling time is 15 hours. The material of the ball mill is agate, the capacity is 250mL, the amount of raw materials added is 7.2g, and the number of large, medium and small balls is 5, 30 and 45 respectively. The speed of ball milling is 580r / min, and there is no time interval between forward and reverse rotation; alternately every 90min.

[0052] (3) Add n-butyryl chloride to the ball-milled raw material, the ratio of raw material to n-butyryl chloride is 1:1 (w / w). Ball milling again, the material of the ball milling tank is zirconia, the capacity is 100mL, the number of large, medium and small balls is 0, 40, 60 respectively, the mass ratio o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com