Fermentation linkage device and method for realizing fermentation linkage

A technology of linkage device and realization method, applied in biochemical cleaning device, biochemical equipment and method, enzymology/microbiology device, etc. Acquisition and analysis of insufficient credibility, affecting production or engineering design decisions and other issues, to achieve the effect of increasing experimental credibility, shortening the research and development cycle, and shortening the research cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

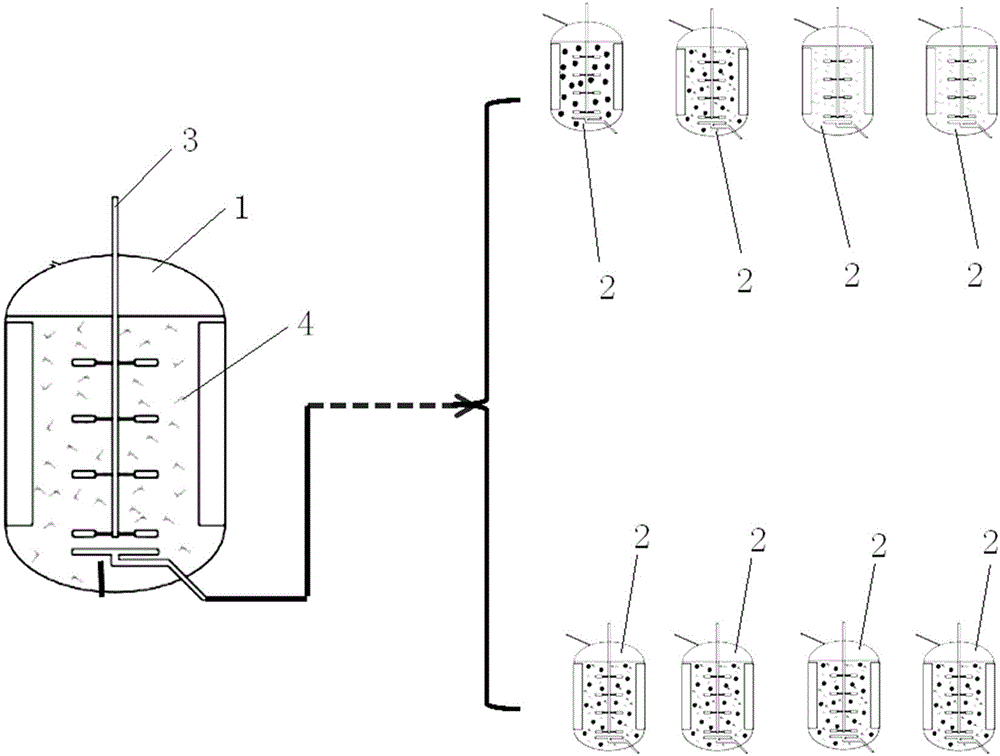

Embodiment 1

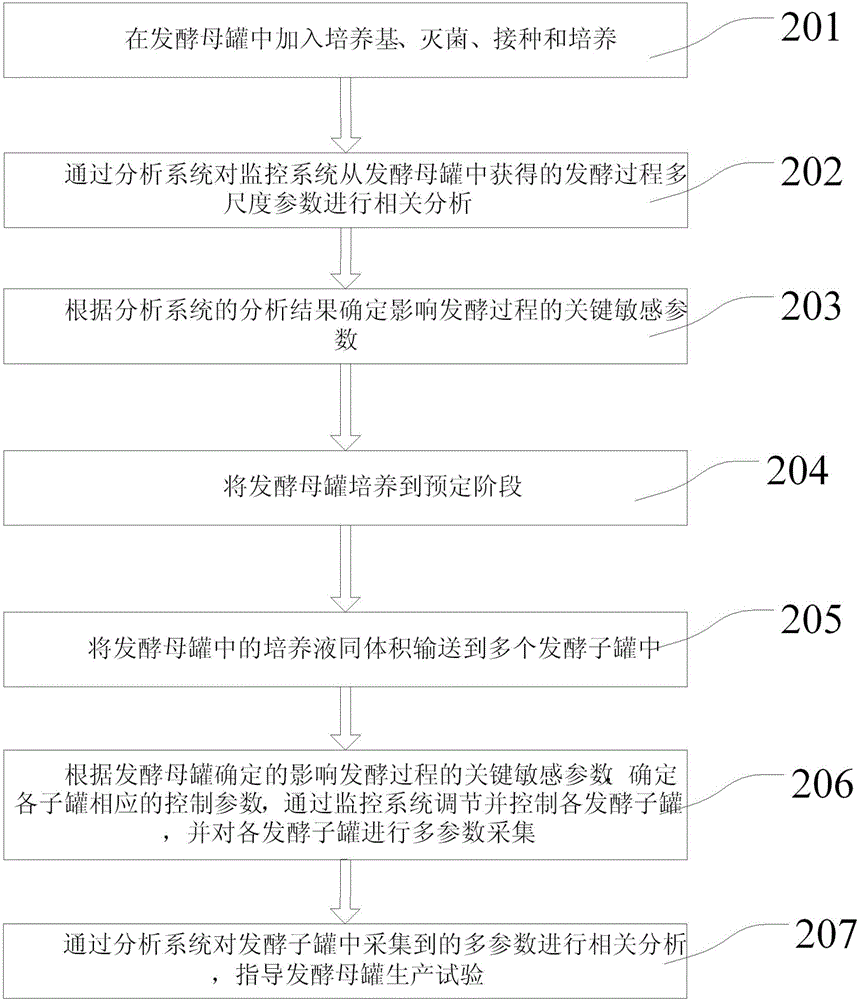

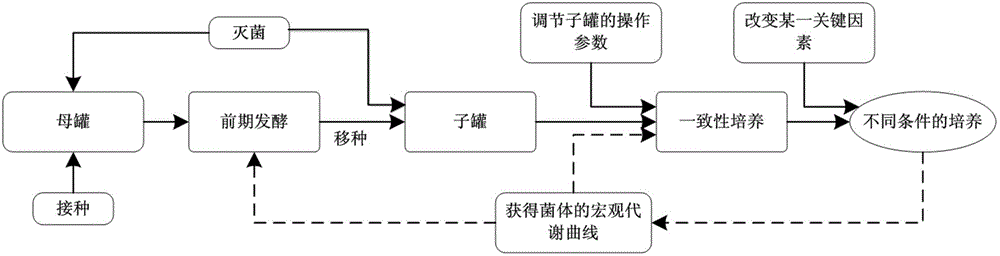

[0067] Four parallel 5L fermentation sub-tanks, including a 50L fermentation yeast tank and electronic monitoring control system and data analysis system, the fermentation yeast tank is connected to each tank of the fermentation sub-tank through pipelines to realize fermentation from the mother tank The liquid is transported to each sub-tank, and each fermenter of the fermentation sub-tank and the fermenter of the fermenting yeast tank can realize pH, DO, volume, tail carbon concentration, tail oxygen concentration, oxygen uptake rate (OUR), carbon dioxide Online collection and comparative analysis of release rate (CER), respiratory quotient (RQ), viable cell concentration and other parameters.

[0068] Utilize the present invention to rhodomonas capsulata ( Rhodopseudomonas capsulatus ) Pilot-scale research on the production process of coenzyme Q10;

[0069] Strains: Rhodomonas capsulatus (select strains from Zhejiang NHU Biopharmaceutical Company).

[0070] The specific s...

Embodiment 2

[0082] The experimental device consisting of 8 parallel 5L fermentation sub-tanks and 1 500L fermenting yeast tank can be used to investigate the influence of shear stress at a specific stage of the fermentation process and changes in the ambient temperature of key factors on fermentation metabolism.

[0083] In this example, the optimization research on the fermentation process of rifamycin, the production strain is: Nocardia mediterranei ( Nocardiamediterranei ), the experimental steps are as follows:

[0084] (1) Incline medium (%): 3.0 sucrose, 0.5 peptone, KCl0.05, FeSO 4 0.001, KH 2 PO 4 0.1, MgSO 4 ·7H 2 O0.05, agar 1.8, pH7.0, the balance is water. Streak inoculation of the seeds on a flat plate with a slant medium, at 28°C, for 48 hours, with a relative humidity of 30-60%, and a culture period of 12-15 days.

[0085] (2) Seed medium (%): glucose 2.0, bean cake powder 1.0, peptone 1.0, KH 2 PO 4 0.01, KNO 3 0.05, the balance is water. The culture temperature...

Embodiment 3

[0093] The experimental device consists of four 2L fermentation sub-tanks and one 50L fermentation yeast tank. This combination can be used to investigate the optimization of pH value control strategies at different stages of microaerobic and anaerobic fermentation processes such as lactic acid, ethanol, and caproic acid. Aseptically transfer the 50L or larger production tank to a specific stage of culture broth into a sterile 2L fermenter sub-tank, by adjusting the ratio of air and nitrogen in the intake, and combining the collected fermenter sub-tank And the fermentation process parameter information of the fermenting yeast tank, control the bacterial state in each fermenting sub-tank to be consistent with that of the fermenting yeast tank, and then change the different pH control levels in the sub-tank, after cultivating for a period of time, perform multi-parameter correlation analysis, The optimal pH control strategy at this stage is obtained to guide the production of yea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com