Preparation method of polycrystalline silver platinum alloy plasma thin-film material

A plasma and thin-film material technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of complicated preparation process, achieve low loss, small surface roughness, and great application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] To clean the monocrystalline silicon substrate, put the pre-cut silicon wafer of 15 mm×8 mm into acetone for 8-10 minutes and ultrasonically clean it for 8-10 minutes, then put it in absolute ethanol for 8-10 minutes, and then place the The slices were put into ultrapure water and sonicated for 8-10 minutes. After immersing the cleaned substrate in 4% hydrofluoric acid for 20 seconds, take it out and dry it.

[0032] Put the cleaned substrate into the sputtering chamber, and place the prepared multiple silver-platinum alloy composite targets on the sputtering target position (according to different composition requirements, place different numbers of platinum sheets respectively).

[0033] Ag was deposited on a silicon substrate by DC reactive magnetron sputtering 1-x Pt x Alloy thin film, use the imported vacuum molecular pump to pump the back vacuum to 1.5×10 -4 Pa. In the DC reactive magnetron sputtering deposition step, argon is the reactive sputtering gas, the...

Embodiment 2

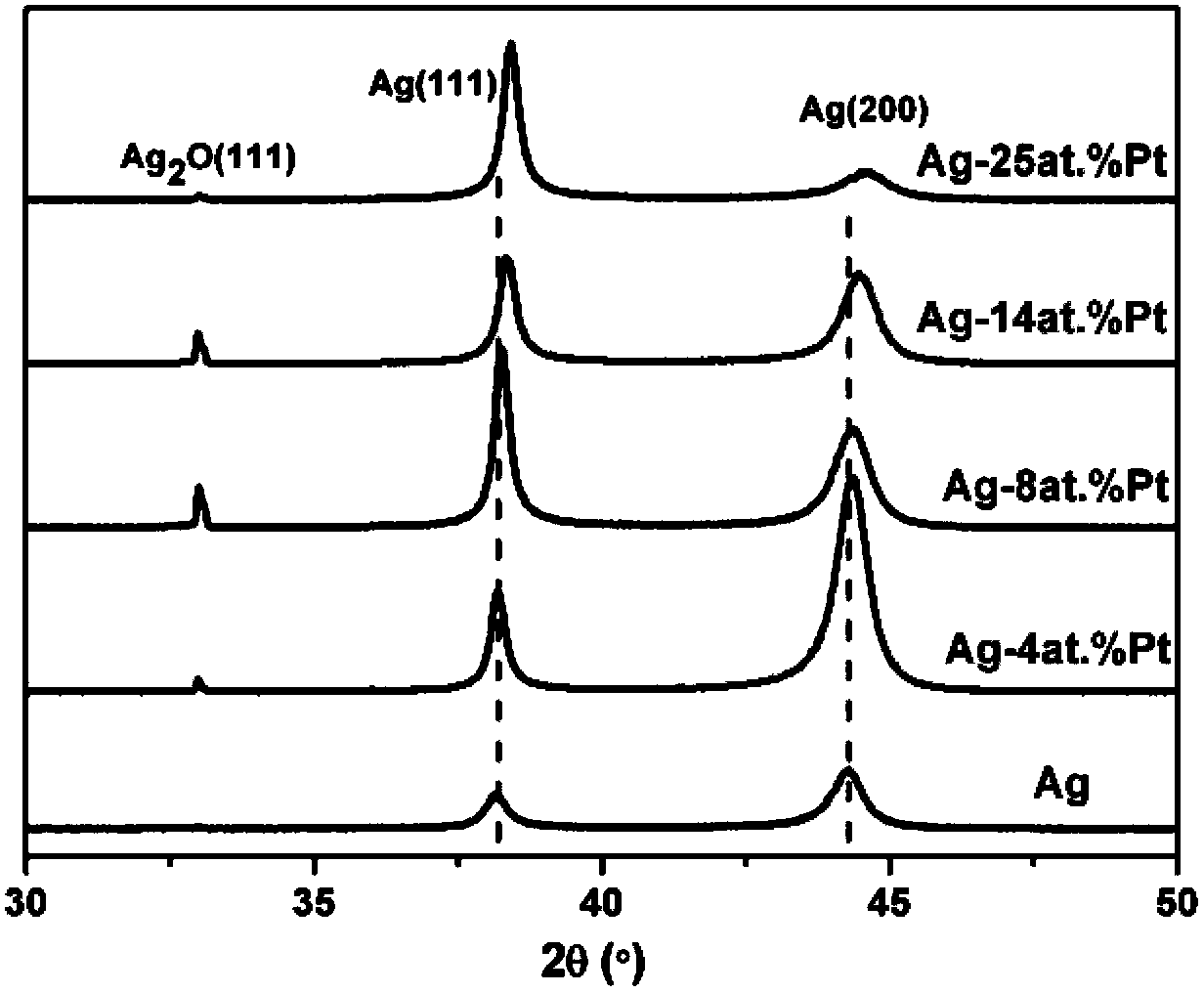

[0037] As in Example 1, four platinum sheets and a silver target are used to form a composite target, and the silver-platinum alloy film is obtained according to the process in Example 1, and the composition of the film is Ag-25at%Pt alloy obtained by X-ray photoelectron spectroscopy analysis. film.

[0038] The tube furnace GSL-1500X-50 with argon protection function produced by Hefei Kejing Company was used for annealing, and the annealing temperatures were set at 100 °C, 200 °C and 300 °C, respectively. Utilize X-ray diffractometer to obtain the diffractogram (as Figure 4 As shown), the crystal phase and grain size distribution were analyzed, and the grain size in the obtained alloy film was dominated by Ag (200) orientation, and the average grain size was about 15 nm.

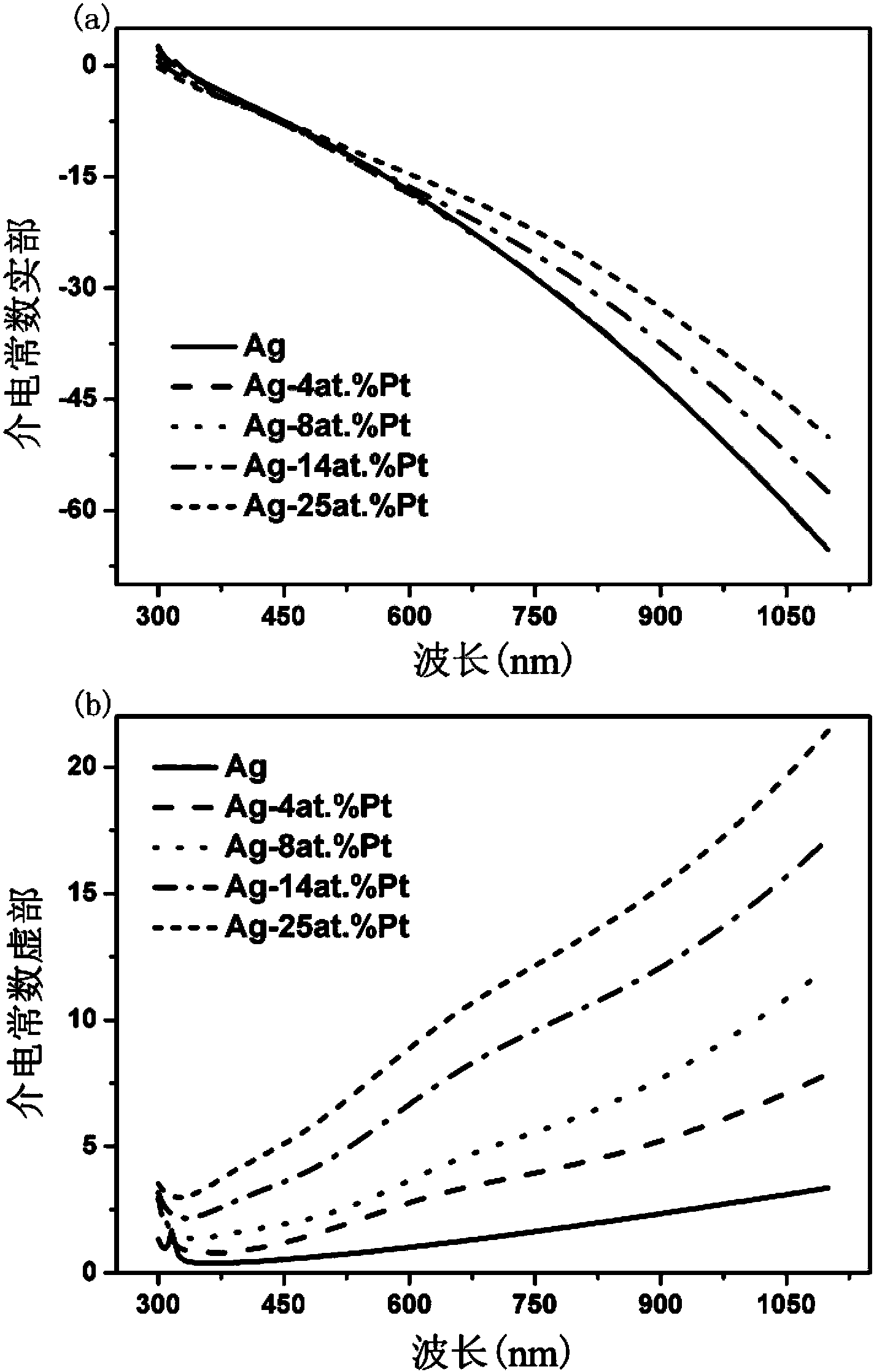

[0039] Utilize the ellipsometer produced by J.A. Woollam Company of the United States to measure the dielectric function of the Ag-25at%Pt alloy film after different annealing temperatures, such as Figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com