UV (ultraviolet) photocured water-based fluorine-containing polyurethane latex film and preparation method thereof

A polyurethane emulsion, polyurethane technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of low double bond content, poor alcohol resistance, low gloss, etc., and achieve improved mechanical properties, strong mechanical properties, and good acid resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A UV light-curable water-based fluorine-containing polyurethane latex film, that is, adding 3.73% of photoinitiator IRGACURE 184 to the UV-curable water-based fluorine-containing polyurethane emulsion by weight percentage and stirring evenly, and coating on a tetrafluoroethylene board , dried at 60°C to constant weight, and then cured by UV radiation on a UV curing machine to obtain a UV curable water-based fluorine-containing polyurethane latex film with a thickness of 0.35mm;

[0057] Described UV curable water-based fluorine-containing polyurethane emulsion, calculated in parts by weight, its raw material composition and content are as follows:

[0058] Polycarbonate diol 40 parts

[0059] Isophorone diisocyanate trimer-fluoroalcohol adduct 100 parts

[0060] Chain extender 4 parts

[0061] 20 parts of hydroxyethyl acrylate

[0062] Pentaerythritol triacrylate 20 parts

[0063] Neutralizer 4 parts

[0064] Catalyst 0.02 part

[0065] Thinner 20 parts

[0066] ...

Embodiment 2

[0098] A UV light-curable water-based fluorine-containing polyurethane latex film, that is, adding 4% of the photoinitiator IRGACURE 907 to the UV-curable water-based fluorine-containing polyurethane emulsion by weight percentage and stirring evenly, and coating on the tetrafluoroethylene board , dried at 60° C. to constant weight, and then cured by UV radiation on a UV curing machine to obtain a UV curable water-based fluorine-containing polyurethane latex film with a thickness of 0.05 mm.

[0099] A kind of UV curing water-based fluorine-containing polyurethane emulsion used above, calculated in parts by weight, its raw material composition and content are as follows:

[0100] Polycarbonate diol 80 parts

[0101] Isophorone diisocyanate trimer-fluoroalcohol adduct 120 parts

[0102] Chain extender 8 parts

[0103] 40 parts of hydroxyethyl acrylate

[0104]Pentaerythritol triacrylate 40 parts

[0105] Neutralizer 6 parts

[0106] Catalyst 1.0 parts

[0107] Thinner 40 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

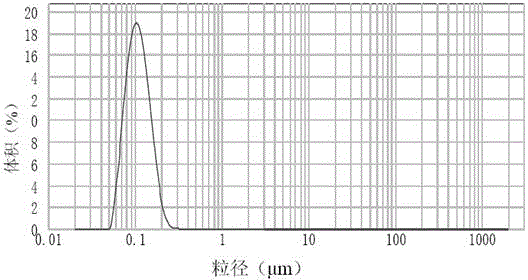

| The average particle size | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com