Method for preparing glutathione through enzyme method

A technology for glutathione and enzymatic preparation, applied in fermentation and other fields, can solve the problems of unsolved enzyme activity stability, affecting production speed, and unable to solve mutual inhibition and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1G

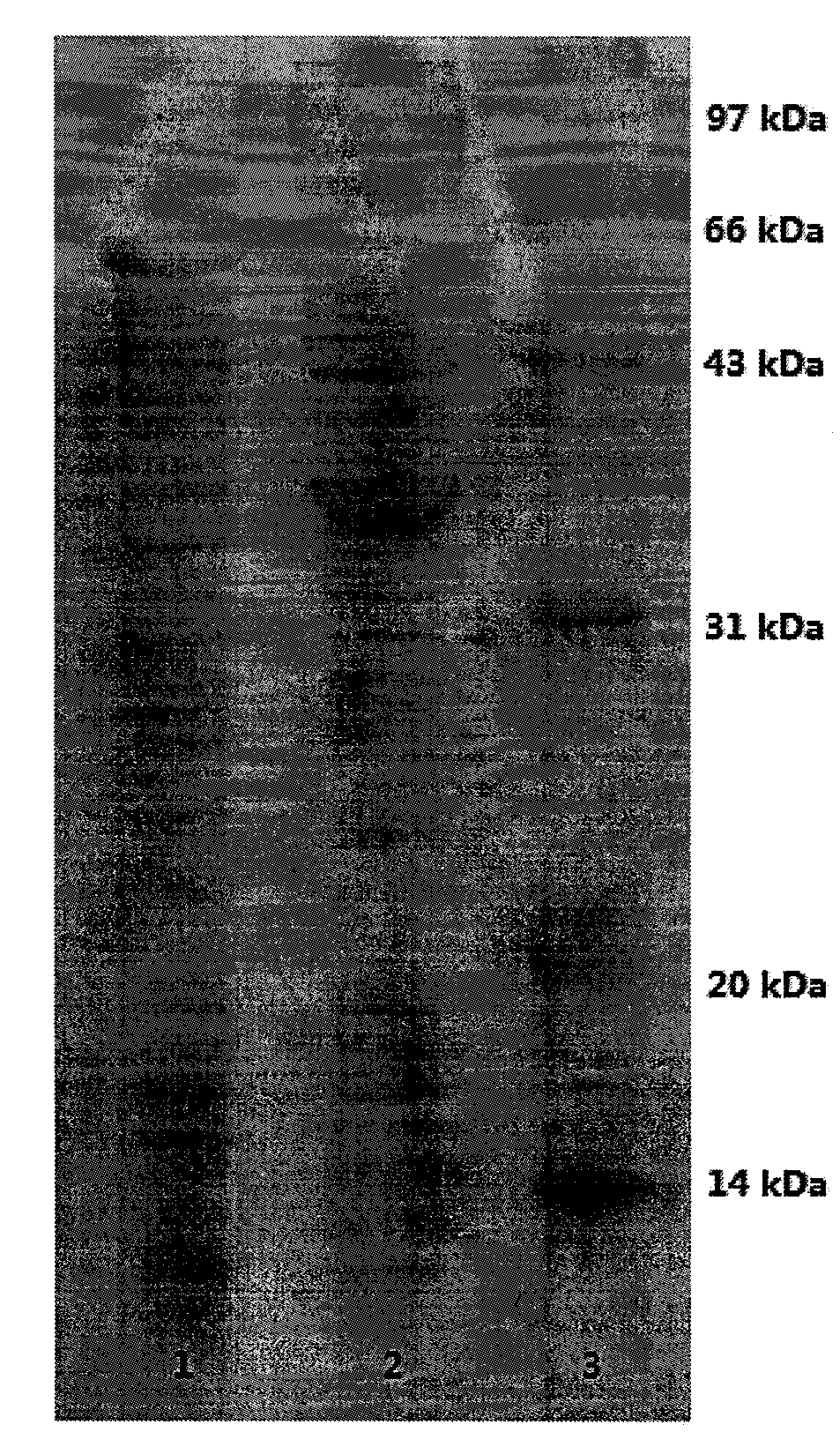

[0108] The preparation of embodiment 1GSH I enzyme and GSH II enzyme

[0109] The GSH I enzyme and GSH II enzyme in the method of the present invention can be obtained commercially, or are artificially modified enzymes having the same catalytic function.

[0110] The preparation process of GSH I enzyme and GSH II enzyme is as follows:

[0111] According to the gsh I and gsh II gene sequences (GenBank: X03954.1 and X01666), two pairs of amplification primers were designed and synthesized by Zhongmei Taihe Biotechnology Co., Ltd. The primer sequences are as follows:

[0112] gshI sense primer: 5'-C CCATGG TCCCGGACGTATCACAGGCGCTG-3';

[0113] gshI antisense primer: 5'-C GGATCC TCAGGCGTGTTTTTCCAGCCACAC-3';

[0114] gsh II sense primer: 5'-C CCATGG TCAAGCTCGGCATCGTGATGG-3';

[0115] gsh II antisense primer: 5'-C GGATCC TTACTGCTGCTGTAAACGTGC-3'.

[0116] The DNA of Escherichia coli (Escherichia coli) K12 strain (purchased from Tiangen Biochemical Technology Co., Ltd.) wa...

Embodiment 2

[0121] The determination of embodiment 2 reaction time

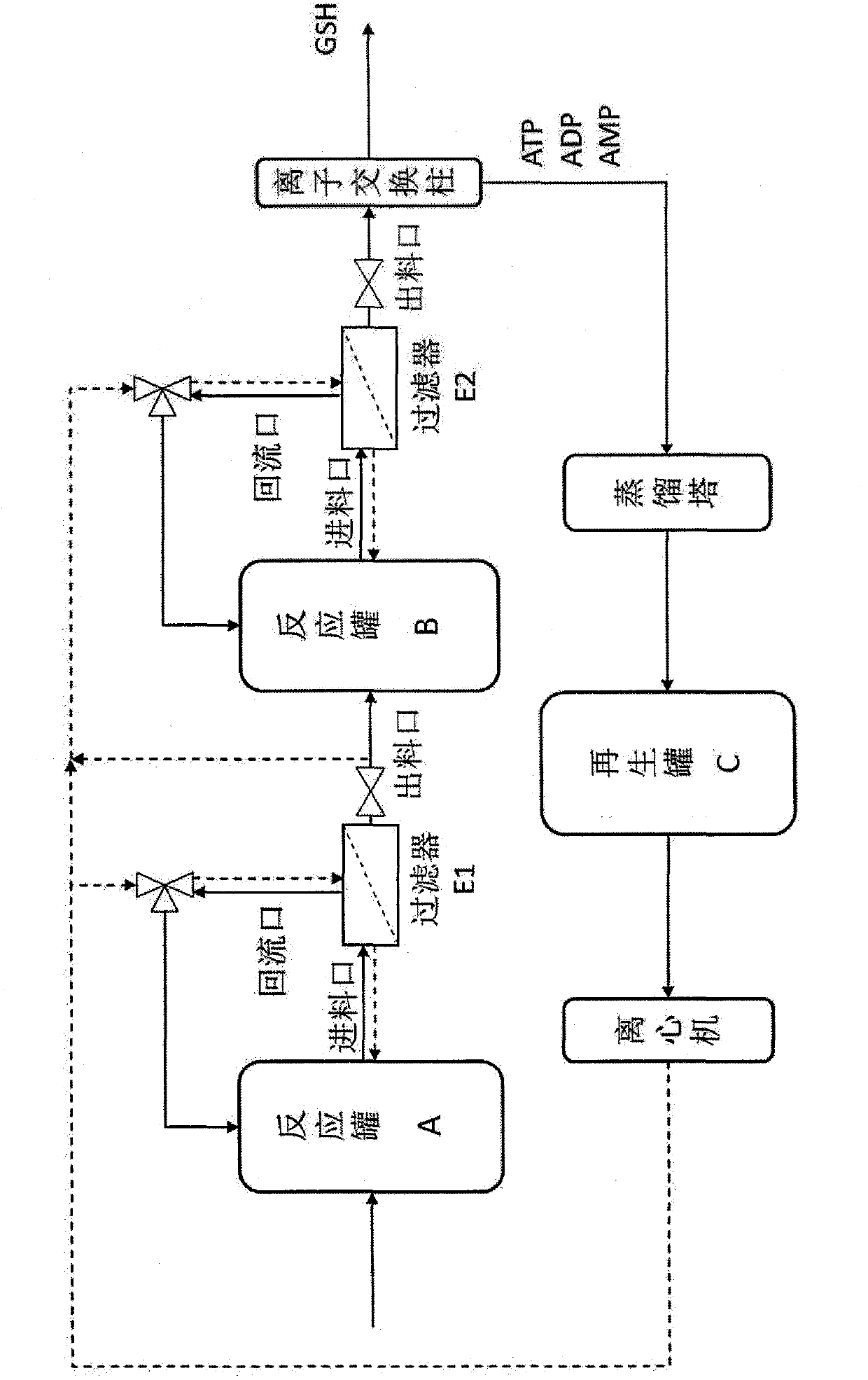

[0122] see figure 1 , prepare the process flow sheet of GSH according to the present invention and carry out following reaction:

[0123] (1) Generate γ-glutamylcysteine (γ-GluCys) in reaction tank A:

[0124] In reaction tank A, the reaction system 1 of 100L sterile water is the solution that contains substrate 600g glutamic acid and 400g cysteine, and 600g Tris, 1100g potassium chloride, 870g sodium chloride and 800g magnesium chloride, in reaction Add 5 g of GSH I enzyme to system 1, add potassium hydroxide to adjust the pH value to 8.5, and add ATP to start the reaction. During the reaction, the pH was controlled to be constant at 8.5, and the temperature was 40°C.

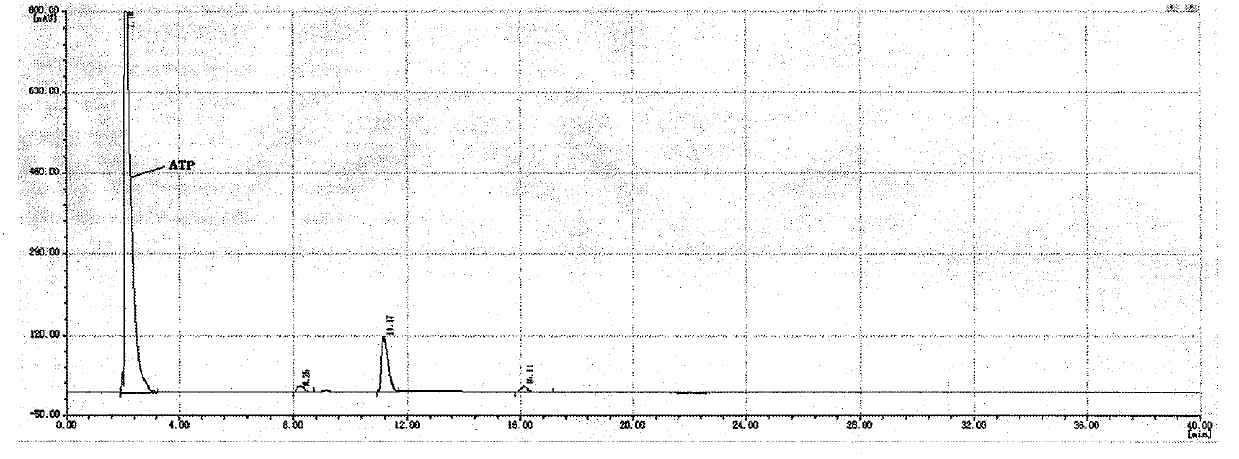

[0125] Use high-performance liquid chromatography (HPLC) to detect the production of γ-glutamylcysteine at 0, 1, 2, 3, 4, and 5 hours of the reaction, see image 3 , Figure 4 and Figure 5 . image 3 It is the HPLC collection of illustrative ...

Embodiment 3

[0133] The preparation of embodiment 3 glutathione

[0134] see figure 1 , prepare glutathione according to the following steps according to the process flow chart of the present invention for preparing GSH:

[0135] (1) Generate γ-glutamylcysteine (γ-GluCys) in reaction tank A:

[0136] In reaction tank A, the reaction system 1 of 100L sterile water is the solution that contains substrate 600g glutamic acid and 400g cysteine, and 600g Tris, 1100g potassium chloride, 870g sodium chloride and 800g magnesium chloride, in reaction Add 5 g of GSH I enzyme to system 1, add potassium hydroxide to adjust the pH value to 8.5, and add ATP to start the reaction. During the reaction, the pH was controlled to be constant at 8.5, and the temperature was 40°C. After 3 hours, the amount of ATP used was about 1200g.

[0137] High-performance liquid chromatography (HPLC) detects that the production of γ-glutamylcysteine is about 6.6g / L, and more than 90% of ATP is converted into ADP (A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com