A production system and method for caprolactam dehydration

A technology of caprolactam and production system, which is applied in the field of caprolactam dehydration production system, can solve the problems of high comprehensive energy consumption, different heat grades, changes in water content, etc., and achieves the effect of reducing steam consumption and high steam utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

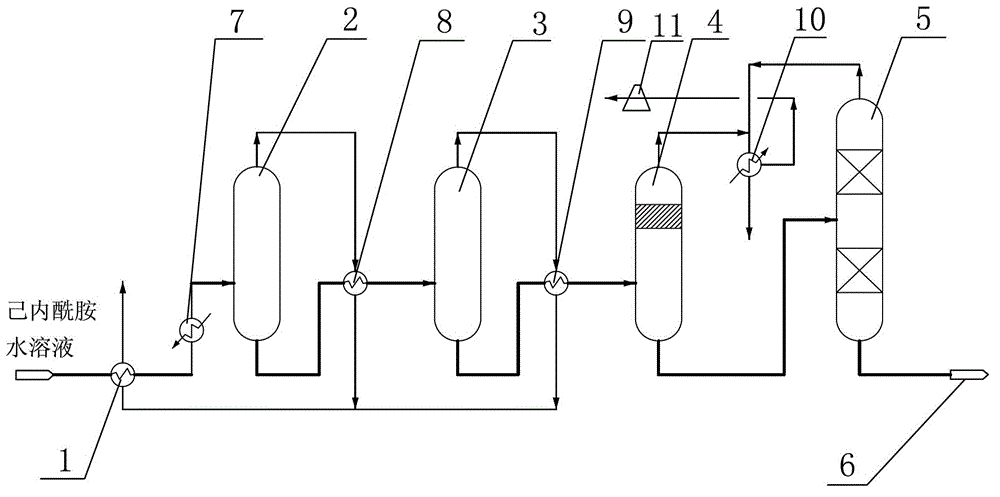

[0025] The invention discloses a production system for caprolactam dehydration, such as figure 1 As shown, it includes a feed preheater 1, a first-effect evaporator 2, a second-effect evaporator 3, a three-effect evaporator 4, a rectification tower 5 and a caprolactam dehydration storage tank 6, and the feed preheater 1 passes through a one-effect exchange Heater 7 is connected to the inlet of first-effect evaporator 2, the lower end material outlet of first-effect evaporator 2 is connected to the inlet of second-effect evaporator 3 through second-effect heat exchanger 8, and the upper end steam outlet of first-effect evaporator 2 is connected to second-effect evaporator 2. The lower end material outlet of the second effect evaporator 3 is connected to the inlet of the third effect evaporator 4 through the third effect heat exchanger 9, and the upper steam outlet of the second effect evaporator 3 is connected to the third effect heat exchanger 9 , The material outlet at the lo...

Embodiment 2

[0029] The invention discloses a production system for caprolactam dehydration, such as figure 1 As shown, it includes a feed preheater 1, a first-effect evaporator 2, a second-effect evaporator 3, a three-effect evaporator 4, a rectification tower 5 and a caprolactam dehydration storage tank 6, and the feed preheater 1 passes through a one-effect exchange Heater 7 is connected to the inlet of first-effect evaporator 2, the lower end material outlet of first-effect evaporator 2 is connected to the inlet of second-effect evaporator 3 through second-effect heat exchanger 8, and the upper end steam outlet of first-effect evaporator 2 is connected to second-effect evaporator 2. The lower end material outlet of the second effect evaporator 3 is connected to the inlet of the third effect evaporator 4 through the third effect heat exchanger 9, and the upper steam outlet of the second effect evaporator 3 is connected to the third effect heat exchanger 9 , The material outlet at the lo...

Embodiment 3

[0033] A kind of production method of caprolactam dehydration of the present invention, as figure 1 As shown, it specifically includes the following steps:

[0034] (1) Send the 30% caprolactam aqueous solution into the feed preheater 1, and then send it to the first-effect evaporator 2 after being heated by the first-effect heat exchanger 7, at a temperature of 115°C and a pressure of 0.2MPaG. Evaporation operation, the bottom of the first-effect evaporator 2 obtains a caprolactam aqueous solution with a concentration of 38%, and the water vapor evaporated from the top of the first-effect evaporator 2 is sent to the second-effect heat exchanger 8 as a heating heat source;

[0035](2) After the caprolactam aqueous solution with a concentration of 38% is heated by the second-effect heat exchanger 8, it is sent to the second-effect evaporator 3 by using the pressure difference or potential difference, and evaporated at a temperature of 105°C and a pressure of 0.05MPaG Operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com