Method for preparing environment-friendly and high-efficiency biological organic fertilizer by using distilled spirit vinasse

A bio-organic fertilizer and distiller's grain technology, which is applied to organic fertilizers, fertilizers made from biological waste, fertilizer mixtures, etc., can solve the problems of complex components of distiller's grains, high water content, and difficulty in utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

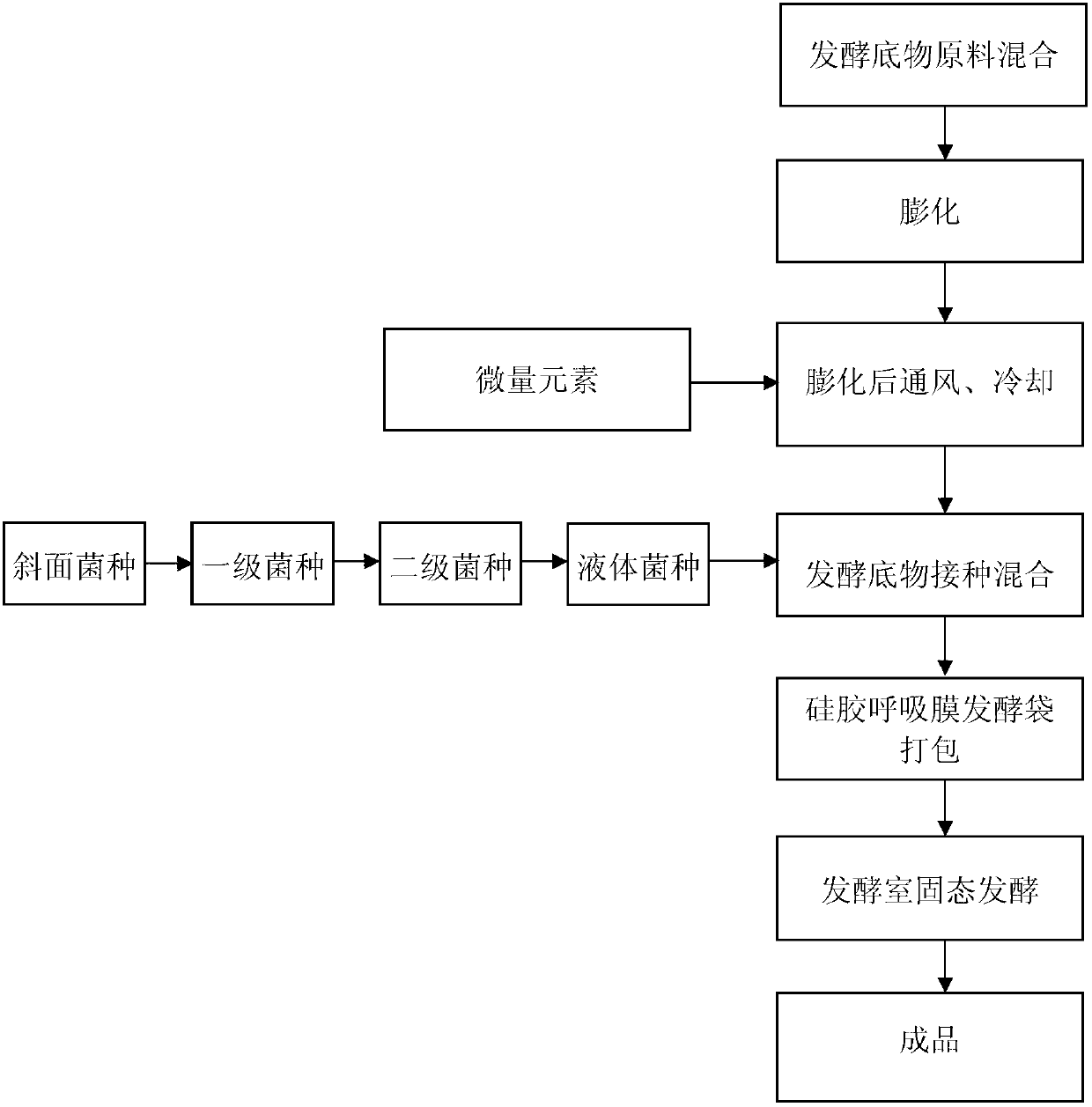

[0065] see figure 1 , prepare the bio-organic fertilizer of the present embodiment according to the following method:

[0066] 1. Accurately weigh 100kg of humic acid, 600kg of distiller's grains, 100kg of sunflower husk powder, 100kg of ammonium sulfate, 50kg of potassium chloride, and 50kg of corn steep liquor, and mix them evenly to make a fermentation substrate. The moisture content of the fermentation substrate is 30%.

[0067] 2. After the raw materials of the fermentation substrate are prepared in proportion, the twin-screw extrusion extruder is subjected to 0.4MPa saturated steam and extruded at 150°C.

[0068] 3. After the fermentation substrate is puffed, it is transported to the wet material mixer, and compressed air is introduced to reduce the temperature of the fermentation substrate to 35°C, and at the same time, MnSO is added 4 ·H 2 O0.05%, CaCO 3 2%, MgSO 4·7H 2 O0.2%, ZnSO 4 0.05% and FeSO 4 0.1% (both are percentages of the weight of the fermentatio...

Embodiment 2

[0109] see figure 1 , prepare the bio-organic fertilizer of the present embodiment according to the following method:

[0110] 1. Accurately weigh 50kg of humic acid, 500kg of distiller's grains, 150kg of sunflower husk powder, 100kg of ammonium sulfate, 100kg of potassium chloride, and 100kg of corn steep liquor, and mix them evenly to make a fermentation substrate. The moisture content of the fermentation substrate is 30%.

[0111] 2. After the raw materials of the fermentation substrate are prepared in proportion, the twin-screw extrusion extruder is subjected to 0.4MPa saturated steam and extruded at 150°C.

[0112] 3. After the fermentation substrate is puffed, it is transported to the wet material mixer, and compressed air is introduced to reduce the temperature of the fermentation substrate to 35°C, and at the same time, MnSO is added 4 ·H 2 O0.05%, CaCO 3 1%, MgSO 4 ·7H 2 O0.1%, ZnSO 4 0.1% and FeSO 4 0.1% Mix thoroughly and evenly.

[0113] 4. The inoculum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com