Cold resistant and high thermal resistance PPA (Phenyl-Propanolamine)/PETG (Polyethylene Terephthalate Glycol) alloy as well as preparation method and application of alloy

A high heat-resistant and cold-resistant technology, applied in the field of polymer materials, can solve problems such as poor fluidity and processing difficulties, and achieve the effects of high electrical properties, high surface gloss, and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Dry PPA and PETG at 110°C for 3 hours, then mix the dried PPA, PETG, toughener, antioxidant, and processing aids in proportion and send them into the twin-screw extruder. Add alkali-free glass fiber out of the machine, go through twin-screw high-speed continuous shearing, mixing, extruding from the machine head, drawing, drying, pelletizing, exposing to strong magnetism and packaging.

[0033] Screw temperature: first zone: 295°C, second zone 310°C, third zone 320°C, fourth zone 325°C, die head 330°C.

Embodiment 2

[0035] According to the process conditions in Example 1 and the material ratio in Table 1, a cold-resistant and high-heat-resistant PPA / PETG alloy was prepared.

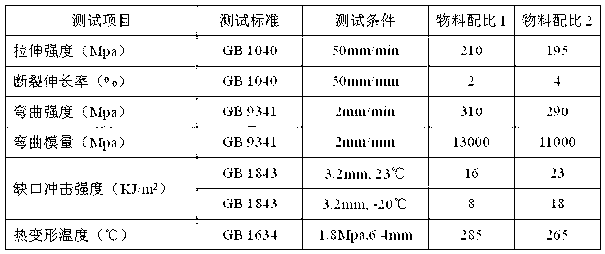

[0036] Table 1 (material ratio is weight percentage)

[0037] components Material ratio 1 Material ratio 2 PPA resin 49 44 PETG resin 10 10 Toughener (grafted SEBS) 5 15 E-glass fiber (988A) 35 30 Antioxidant (1010 / 168) 0.5 0.5 Processing aids (silicone powder) 0.5 0.5

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com