Composite hybrid organic silicon LED (Light Emitting Diode) packaging material, preparation method and applications thereof

A technology of LED packaging and silicone, applied in electrical components, circuits, semiconductor devices, etc., can solve the optical properties such as poor uniformity of silicone packaging materials, insufficient blending, transmittance and refractive index of silicone packaging materials It can solve the problems of non-uniform dispersion, increase cross-linking density, and enhance mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

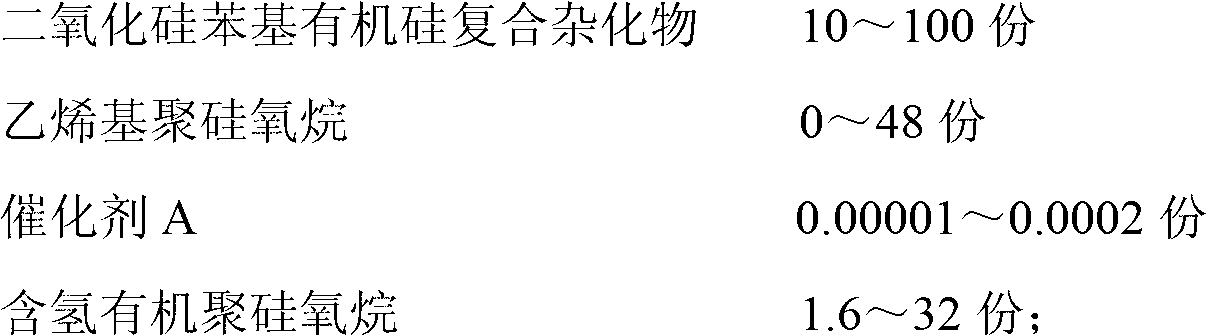

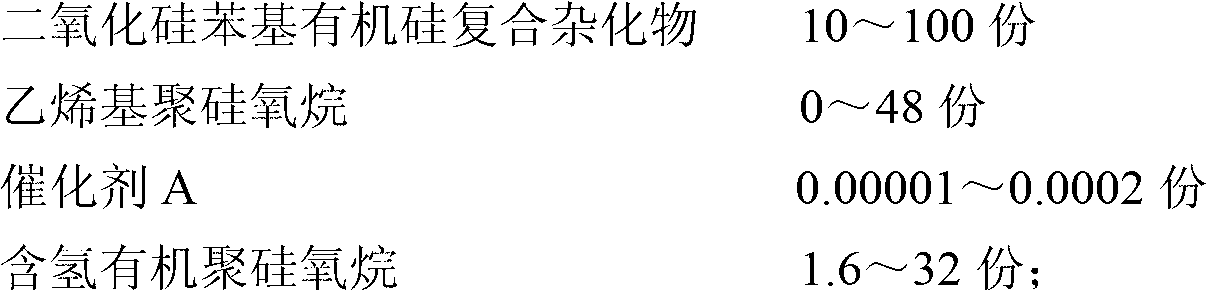

Method used

Image

Examples

Embodiment 1

[0026] (1) Mix 120g of diphenyldimethoxysilane, 25g of γ-(methacryloxy)propyltrimethoxysilane, 6g of nano-silica (120±10nm), 0.80g of dibutyldilauric acid Put tin, 10 g of distilled water and 150 g of tetrahydrofuran into a reactor equipped with a stirrer, a condensing reflux tube and a thermometer, mix and stir evenly, then condense and reflux at 50°C for 9 hours, and remove water and tetrahydrofuran by rotary evaporation at 80°C for 1 hour to obtain Silica phenyl silicone complex hybrid with a vinyl content of 0.57%;

[0027] (2) Take 100 g of the silica phenyl organosilicon complex hybrid in step (1), 0.20 mg of dichlorobis(triphenylphosphine) ((PPh 3 ) 2 Cl 2 ) coordinated platinum complex, 1.60g of hydrogen-containing organopolysiloxane (type 202, industrial grade, hydrogen content 1.5%) were placed in an open container, stirred evenly at room temperature, and then placed at 90°C After reacting under vacuum for 5 hours, the composite hybrid silicone LED packaging mater...

Embodiment 2

[0029] (1) Mix 15g of phenyltrimethoxysilane, 1.50g of vinyltriethoxysilane, 0.91g of nano silicon dioxide (7~40nm), 0.10g of dibutyl tin diacetate, 1.50g of distilled water and 20g of toluene Put it into a reactor equipped with a stirrer, a condensing reflux tube and a thermometer, mix and stir evenly, then condense and reflux for 6 hours at 65°C, and remove water and toluene by rotary evaporation at 70°C for 2 hours to obtain vinyl content of 1.90%. Silica phenyl silicone complex hybrid;

[0030] (2) Take 10g of silica phenyl organosilicon complex hybrid in step (1), 10g of vinyl polysiloxane (SiVi-300, 300mPa s, vinyl mole fraction is 1.92%, Zhejiang Xinan Chemical Industry Co., Ltd. company), 0.01mg tetrahydrofuran as solvent H 2 PtCl 6 (The mass fraction of the solute is 0.2%) and 9.00g of hydrogen-containing polysiloxane (202 type, industrial grade, hydrogen content of 0.18%) are placed in an open container, stirred evenly at room temperature, and reacted under vacuum ...

Embodiment 3

[0032] (1) Mix 75.50g of diphenyldiethoxysilane, 21.50g of vinyl tri-tert-butoxysilane, 5.95g of nano-silica (400±10nm), 0.40g of stannous octoate, 7.2g of distilled water and 110g of n- Put butanol into a reactor equipped with a stirrer, a condensing reflux pipe and a thermometer, mix and stir evenly, then condense and reflux at 60°C for 7 hours, and remove water and n-butanol by rotary evaporation at 85°C for 30 minutes to obtain a vinyl content of 2.75% silica phenyl silicone complex hybrid;

[0033] (2) Take 50g of silica phenyl organosilicon composite hybrid in step (1), 10g of vinyl polysiloxane (SiVi-1000, 1000mPa·s, vinyl mole fraction is 0.8%, Zhejiang Xinan Chemical Industry Co., Ltd. company), 0.06mg isopropanol as solvent H 2 PtCl 6 (The mass fraction of the solute is 0.3%) and 4.20g of hydrogen-containing polysiloxane (202 type, industrial grade, hydrogen content of 0.54%) are placed in an open container, stirred evenly at room temperature, and reacted under vac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com