Preparation method for compound enzyme system for high-efficiency degradation for lignocellulose and application thereof

A technology of lignocellulose and composite enzyme system, applied in the field of preparation of composite enzyme system, can solve the problems of unsuitability for large-scale production, low enzyme activity, poor operability, etc., and achieve broad application prospects and application potential, reducing sugar content The effect of increasing and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The invention provides a preparation method of a composite enzyme system for efficiently degrading lignocellulose, comprising the following steps:

[0020] Step 1, activating Trichoderma reesei strain or its derivative strain;

[0021] Step 2. Prepare the activated Trichoderma reesei strain or its derivative strains into a spore suspension, inoculate it in the seed medium for cultivation, and shake it on a shaking table with a temperature of 28-30°C and a rotational speed of 170-200 rpm Cultivate for 24~36h;

[0022] Step 3: Inoculate the seed culture medium inoculated with the Trichoderma reesei strain or its derivative strains into a fermentation medium with microcrystalline cellulose and corncobs as carbon sources and a mixing ratio of 1:4 for fermenter cultivation.

[0023] In the preparation method of the described compound enzyme system for efficiently degrading lignocellulose, in the step 3, the seed culture medium inoculated with the Trichoderma reesei strain o...

Embodiment 1

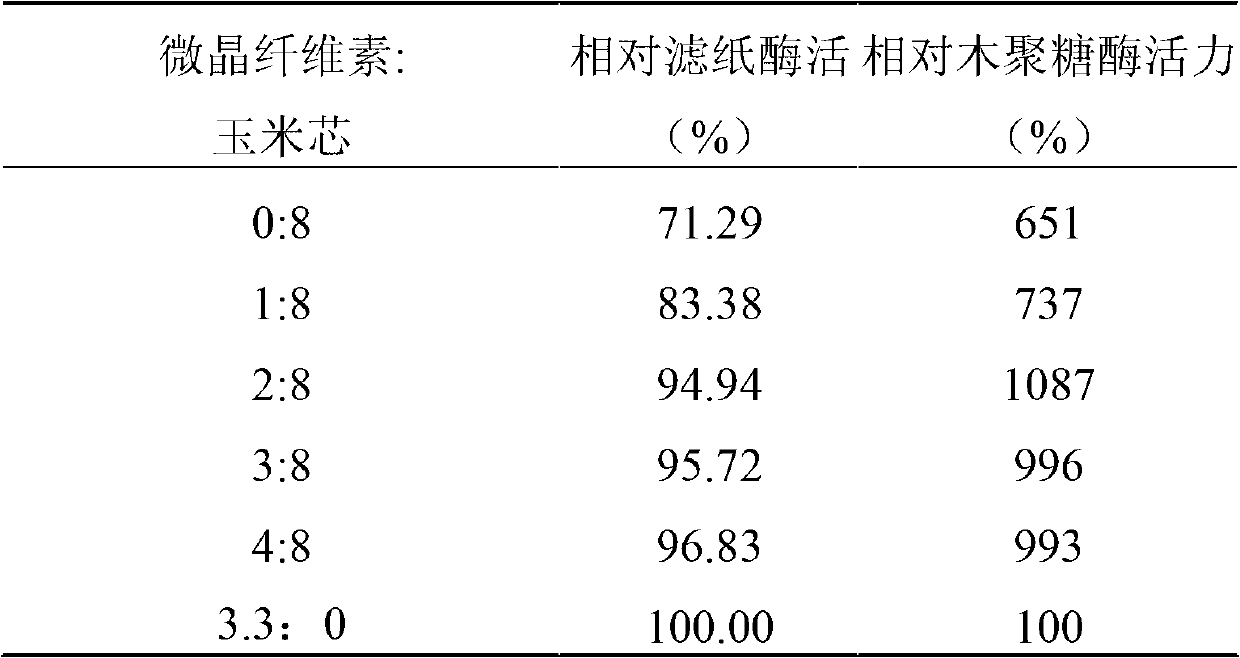

[0045] The activated Trichoderma reesei strain or its derivative strain on the PDA slant medium is prepared into a spore suspension, which is inoculated into a fresh seed medium according to the first percentage of inoculation amount for cultivation. Mix microcrystalline cellulose and corncob in different proportions, take 1.5g raw materials with different mixing proportions and add 50ml fermentation medium solution into a 250ml Erlenmeyer flask, sterilize at 120°C for 15min, inoculate Trichoderma reesei strain or its The seed medium solution of the derived strain was fermented at 28-30°C, 150-220 rpm for 5-7 days, and the supernatant was collected by centrifugation to measure the activity of cellulase and xylanase. The results are shown in Table 1. When microcrystalline cellulose and corn cob were mixed at a ratio of 2:8, the cellulase activity was 94.6% of that when pure microcrystalline cellulose was used as carbon source, and the xylanase activity was 94.6% of pure microcry...

Embodiment 2

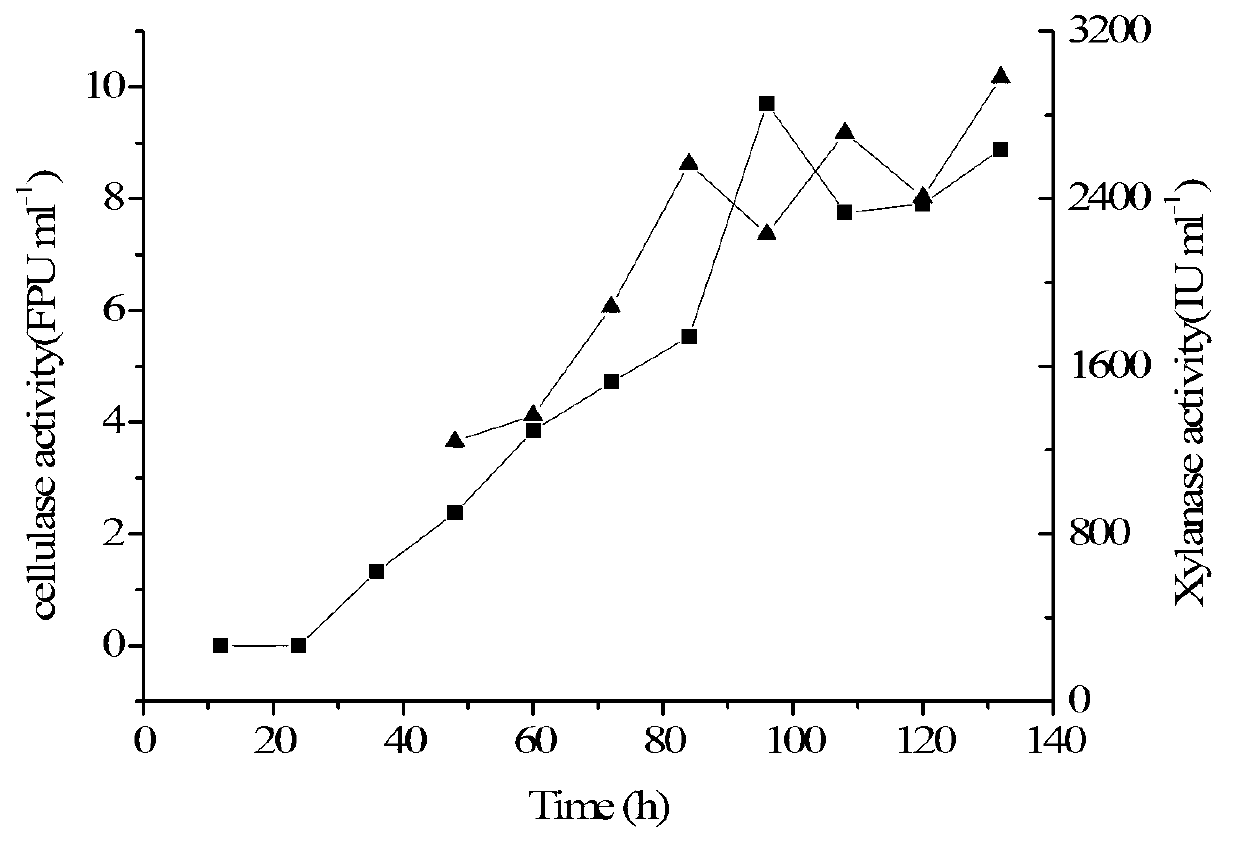

[0049] According to the implementation method in Example 1, the activated Trichoderma reesei strain and its derivative strains were inoculated in the seed medium for cultivation, then inserted into 3L fermentation medium solution containing 150g / L of mixed raw materials and packed into 5l Fermentation in the fermenter, after the fermentation, the cellulase activity and xylanase activity were measured, the results are shown in figure 1 , the cellulase activity reached 9.7IU / ml after 96h, and the xylanase activity reached 3000IU / ml after 132h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com