Nanometer/columnar-like crystal mixing structure thermal barrier coating and preparation method thereof

A hybrid structure and thermal barrier coating technology, applied in coatings, chemical instruments and methods, metal material coating technology, etc., can solve the problem of affecting the reliability and service life of the coating, the inability to fully utilize the columnar crystal structure, Problems such as the decline of the thermal insulation performance of the coating, to achieve the effects of improving anti-sintering performance, high reliability, and improving thermal cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

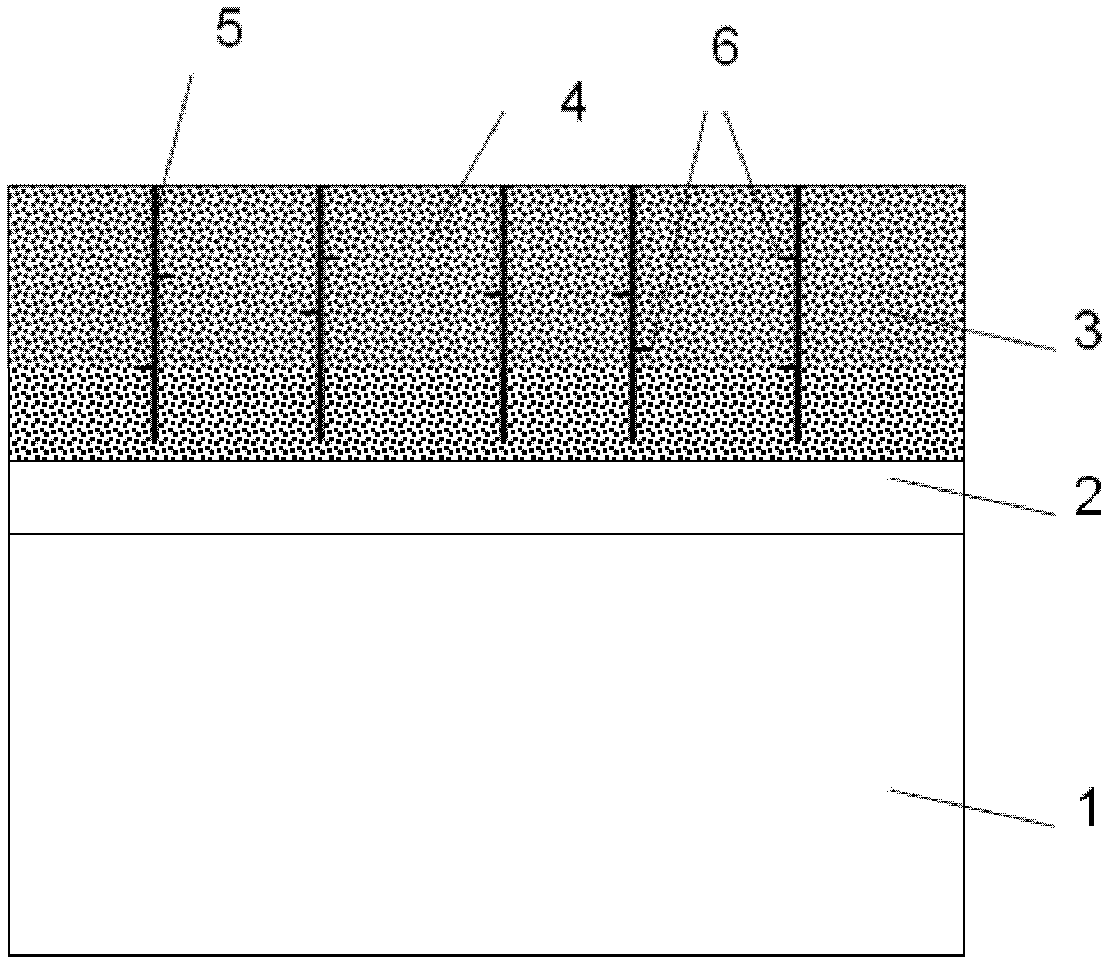

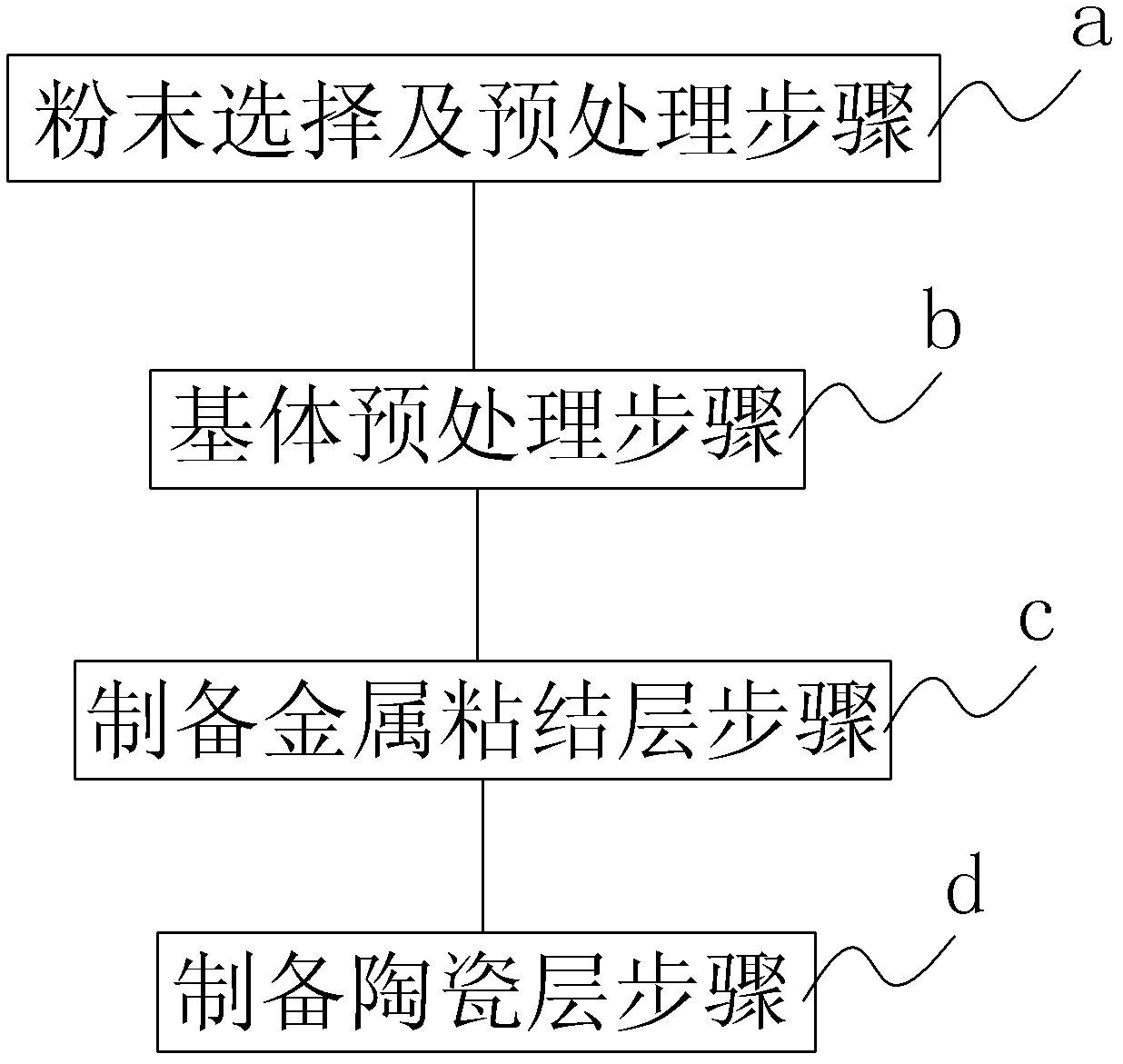

[0062] see figure 2 , figure 2 It is a flow chart of the method of the present invention. The preparation method of the hybrid structure thermal barrier coating of the present invention comprises the following steps:

[0063] Powder selection and pretreatment step a, select nano-agglomerated YSZ spray powder and perform high-temperature sintering or plasma densification treatment; preferably, the nano-agglomerated YSZ spray powder contains 6-8 wt% Y 2 o 3 Partially stabilized ZrO 2 , and the fluidity of the nano-agglomerated YSZ spray powder is less than 60s / 50g, and the bulk density is greater than 1.6g / cm 3 .

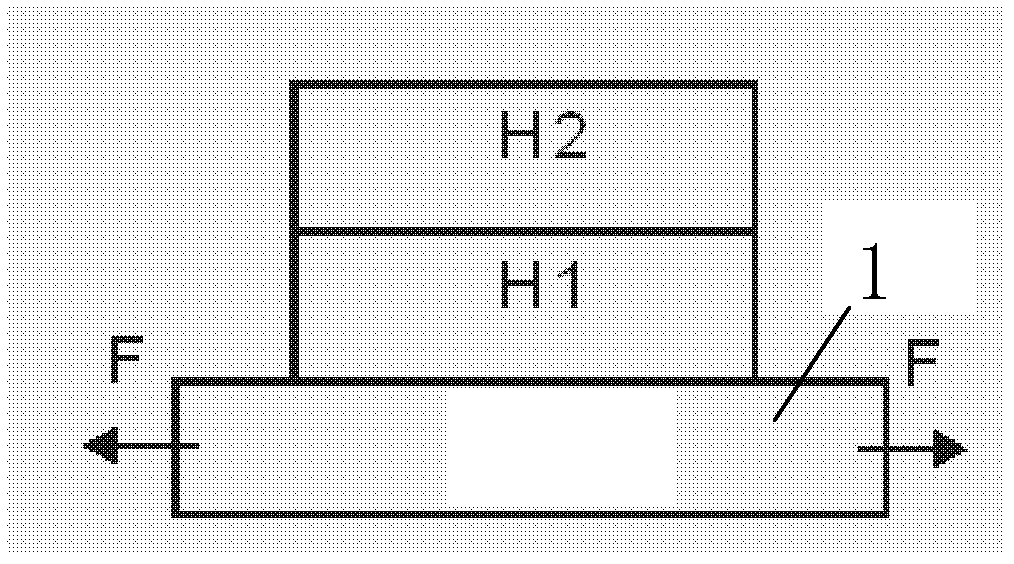

[0064] In the substrate pretreatment step b, the substrate 1 is provided and the substrate 1 is cleaned and sandblasted; the substrate 1 is preferably a high-temperature alloy or heat-resistant steel.

[0065] Prepare the metal bonding layer step c, the metal alloy powder is prepared by plasma spraying or supersonic flame spraying to prepare the metal bonding ...

Embodiment 1

[0085] Example 1: Preparation of coating on the surface of DZ40M superalloy substrate 1

[0086] Step a: Powder selection and preparation

[0087] Select nanometer YSZ agglomerated powder, after powder agglomeration, undergo plasma densification treatment, the particle size range of the sprayed powder is -90μm~+37μm, and the bulk density is 1.74g / cm 3 , the fluidity is 52s / 50g, the powder is used for plasma spraying after drying at 100°C for 2 hours.

[0088] Step b: Substrate 1 pretreatment

[0089] Choose a cobalt-based superalloy, the grade is DZ40M, soak the superalloy substrate 1 in acetone, take it out and dry it after 1 hour; Compressed air blows off residual sand particles on the surface.

[0090] Step c: Preparation of metal bonding layer 2 by supersonic flame spraying

[0091] The preparation of the bonding layer is mainly NiCrAlY metal alloy powder, the particle size range of the powder is -45μm ~ +15μm, according to the preparation process parameters of the met...

Embodiment 2

[0095] Embodiment 2: prepare coating on MGH754Ni-Cr alloy substrate surface

[0096] Step a: Powder selection and preparation

[0097] Select nanometer YSZ agglomerated powder, after powder agglomeration, undergo plasma densification treatment, the particle size range of the sprayed powder is -61μm~+38μm, and the bulk density is 1.85g / cm 3 , the fluidity is 47s / 50g, the powder is used for plasma spraying after drying at 100°C for 2 hours.

[0098] Step b: Substrate 1 pretreatment

[0099] Select the dispersion strengthened NiCr heat-resistant alloy, the grade is MGH754, soak the superalloy substrate 1 in acetone, take it out and dry it after 1 hour; 1 Use compressed air to blow off the residual sand particles on the surface.

[0100] Step c: Preparation of metal bonding layer 2 by plasma spraying

[0101] For the preparation of the bonding layer, the metal alloy powder whose main component is NiCoCrAlY is selected, and the particle size range of the powder is -75μm~+45μm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fluidity | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com