Method for preparing polytetrafluoroethylene dispersion resin with high compression ratio

A technology of polytetrafluoroethylene and dispersed resin, which is applied in the field of polymers, can solve the problems of inability to obtain mechanical and electrical properties, low melt flow, and low compression ratio, and achieve high DC breakdown voltage strength, stable performance, and compression Higher effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

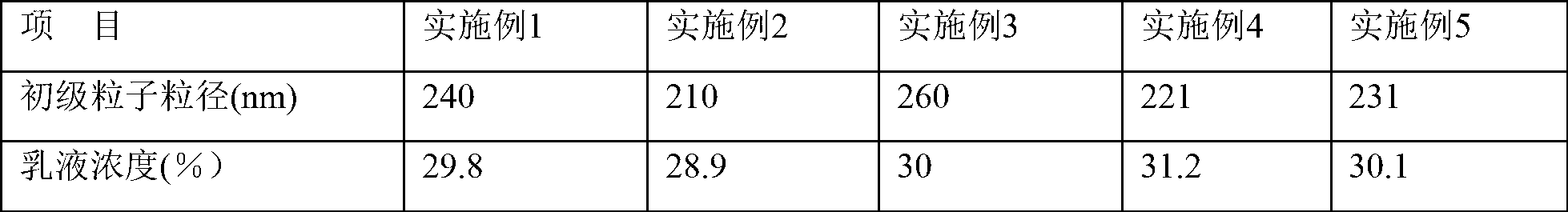

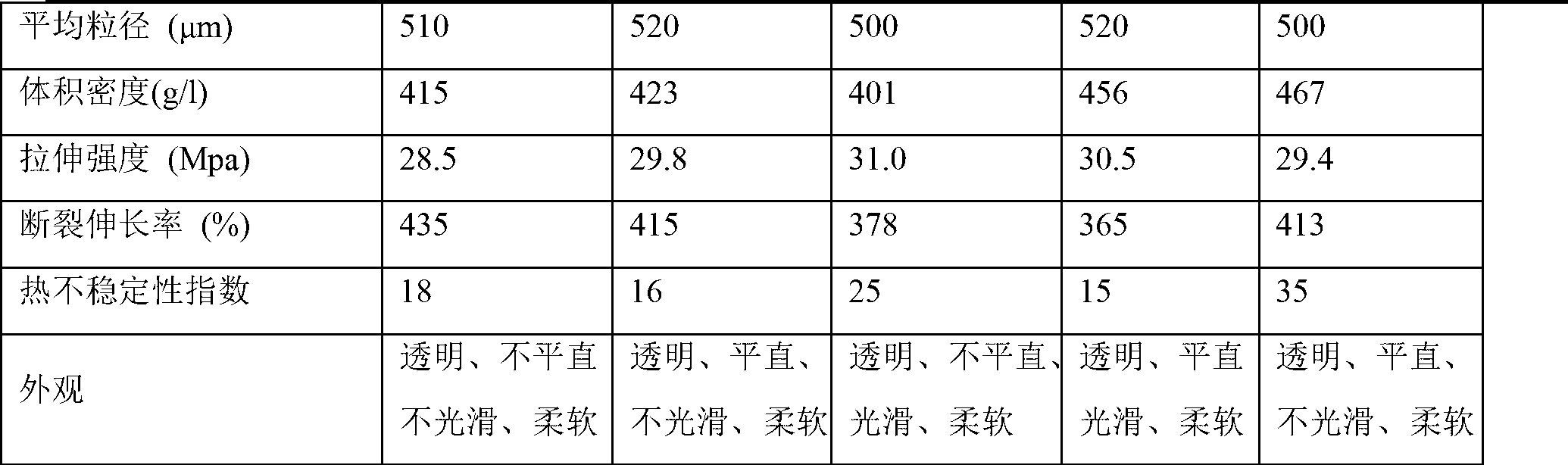

Embodiment 1

[0022] Wash the 2000L stainless steel autoclave equipped with stirring and temperature control system (circulating heating and circulating cooling water), add 1400L deionized water, 60kg of solid paraffin, 420g of succinic acid, 6000ml of 30% (weight percent) ammonium perfluorooctanoate solution , start stirring at 20 rpm and vacuumize, replace with nitrogen three times until the oxygen content is below 30ppm, then vacuumize to -0.098Mpa, fill tetrafluoroethylene until the gauge pressure of the kettle is a slight positive pressure, adjust the temperature control system Control the internal temperature of the polymerization kettle to 70°C, increase the rotation speed to 45 rpm, continue to feed tetrafluoroethylene monomer into the reactor, and keep the internal pressure of the reactor at 1.5Mpa. At the same time, add 8g of initiator ammonium persulfate to start the reaction , After reacting for 0.5 hours, add modifier trifluoroethylene 1000g, continue feeding tetrafluoroethylene...

Embodiment 2

[0025] Wash the 2000L stainless steel autoclave equipped with stirring and temperature control system (circulating heating and circulating cooling water), add 1300L deionized water, 60kg of solid paraffin, 450g of succinic acid, 6000ml of 30% (weight percent) ammonium perfluorooctanoate solution , start stirring at 20 rpm and vacuumize, replace with nitrogen three times until the oxygen content is below 30ppm, then vacuumize to -0.098Mpa, fill tetrafluoroethylene until the gauge pressure of the kettle is a slight positive pressure, adjust the temperature control system Control the internal temperature of the polymerization kettle to 70°C, increase the rotation speed to 45 rpm, continue to feed tetrafluoroethylene monomer into the reactor, and keep the internal pressure of the reactor at 1.5Mpa. At the same time, add 8g of initiator ammonium persulfate to start the reaction , After reacting for 1.0 hour, add modifier hexafluoropropylene 1000g, trifluorochloroethylene 1500g, trif...

Embodiment 3

[0028] Wash the 2000L stainless steel autoclave equipped with stirring and temperature control system (circulating heating and circulating cooling water), add 1400L deionized water, 60kg of solid paraffin, 650g of succinic acid, 6000ml of 30% (weight percent) ammonium perfluorooctanoate solution , start stirring at 20 rpm and vacuumize, replace with nitrogen three times until the oxygen content is below 30ppm, then vacuumize to -0.098Mpa, fill tetrafluoroethylene until the gauge pressure of the kettle is a slight positive pressure, adjust the temperature control system Control the internal temperature of the polymerization kettle to 75°C, increase the speed to 45 rpm, continue to feed tetrafluoroethylene monomer into the reactor, and keep the internal pressure of the reactor at 1.4Mpa, and add 8g of initiator ammonium persulfate at the same time to start the reaction , After reacting for 0.5 hour, add modifier hexafluoropropylene 1500g, trifluorochloroethylene 1000g, trifluoroe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com