Preparation method of polyester type pure solid polycarboxylate high-performance water reducer

A pure solid, polycarboxylate technology, applied in the field of polycarboxylate high-performance water reducers, can solve the problems of abundant synthetic polycarboxylate preparation methods and the inability to fully realize solid polyester type water reducers, and achieve good market competition force and application prospects, avoiding the reduction of separation and concentration efficiency, and reducing the effect of transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

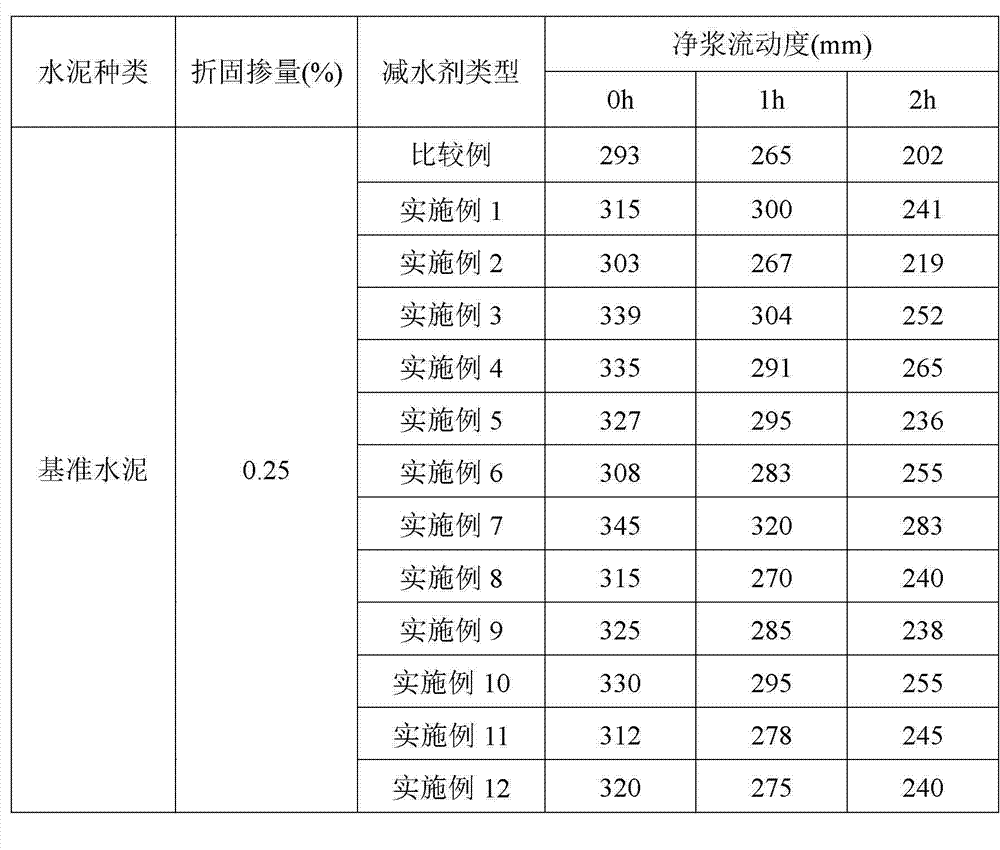

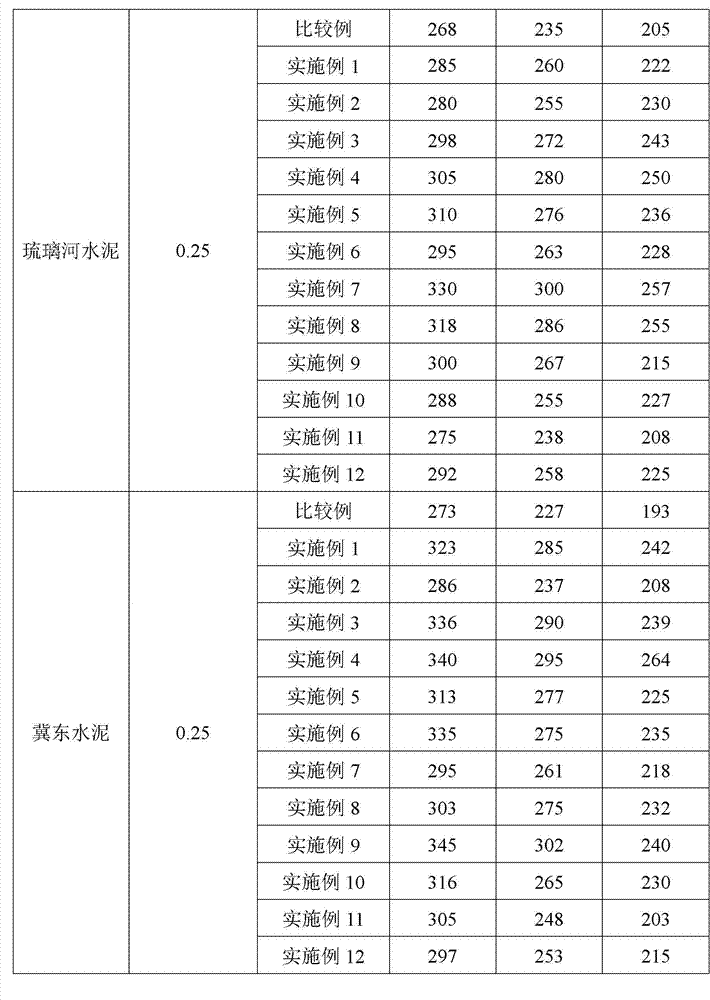

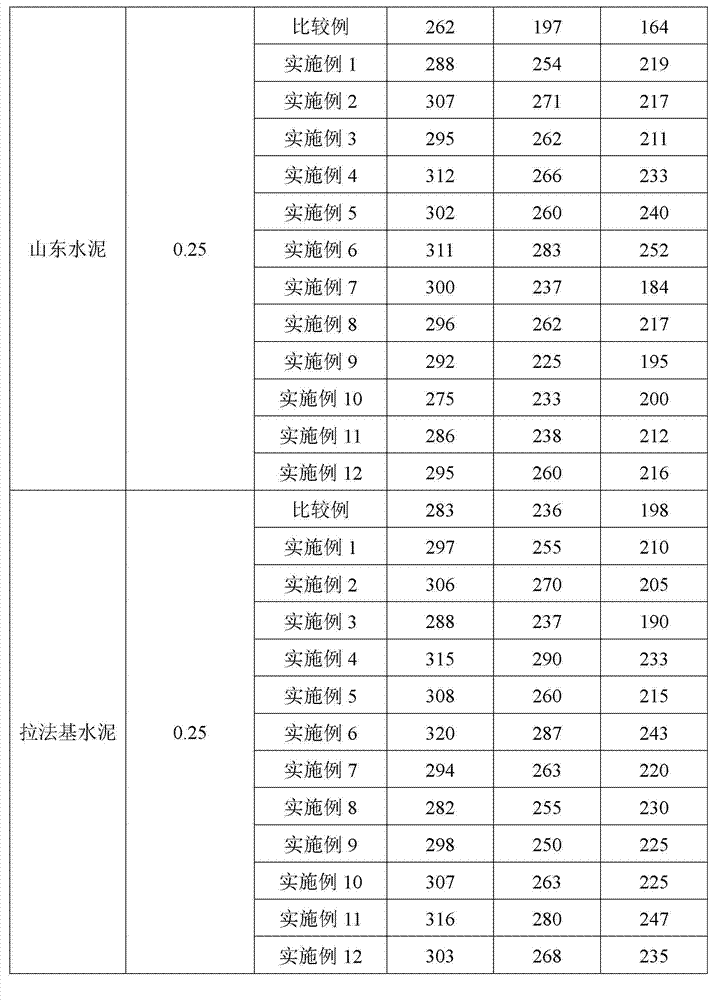

Examples

Embodiment 1

[0023] First, add 100g of methoxypolyethylene glycol (molecular weight: 2500) into the reactor, raise the temperature to 50°C, and when the methoxypolyethylene glycol is in liquid state, add 0.07g of hydroquinone, 14.41g of acrylic acid, 1.5g of p-toluenesulfonic acid, and the stirring time between each addition is 20 minutes. When the temperature rises to 80°C, add 17.16g of cyclohexane, and continue to heat up to 105°C for esterification reaction. The water obtained from the reaction was separated, and after 6 hours of reaction, the cyclohexane was removed by vacuuming to obtain the esterification reaction product; the esterification reaction product was added to the reactor, the temperature was raised to 50°C, and 2.76g of mercapto groups were added to the reactor in turn. Acetic acid, 4.32g of acrylic acid, 0.48g of dibenzoyl peroxide, and the stirring time between each addition is 20 minutes, continue to heat up to 95°C for bulk polymerization, react for 4 hours, stop the ...

Embodiment 2

[0025] After the cement dispersant with a mass fraction of 35% obtained in Example 1 was stored at 6°C for 30 days, its implementation effect was measured.

Embodiment 3

[0027] First, 50g of polyethylene glycol (molecular weight: 500) was added to the reactor, and the temperature was raised to 70°C. When the polyethylene glycol was in a liquid state, 0.65g of phenothiazine, 12.91g of methacrylic acid, 5g of Phosphoric acid, and the stirring time between each feeding is 5 minutes. When the temperature rises to 100°C, 18.87g toluene is added, and the temperature is continued to rise to 110°C to carry out the esterification reaction. Vacuumize the toluene to get the esterification reaction product; put the esterification reaction product into the reactor, heat up to 70°C, add 0.53g of mercaptopropionic acid, 4.8g of acrylic acid, 32.67g of maleic anhydride, 1.64g of azobisisobutyronitrile, and the stirring time between each addition is 5 minutes, continue to heat up to 75°C for bulk polymerization, react for 8 hours, stop the reaction, cool to 25°C, and obtain 106.66g of polyester-type pure The solid reaction product was finally diluted with 130....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com