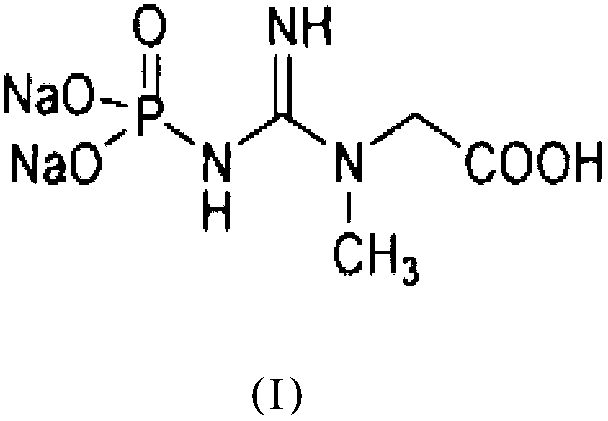

Method of preparing creatine phosphate sodium

A technology of sodium phosphate phosphate and creatine kinase, applied in the biological field, can solve the problems of lack of specific purification method, difficult removal of impurity proteins, high product cost, and achieve the effects of simple and easy separation, easy separation and purification, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] (1) Construct expression strains of creatine kinase and acetate kinase respectively, induce expression and perform crushing treatment

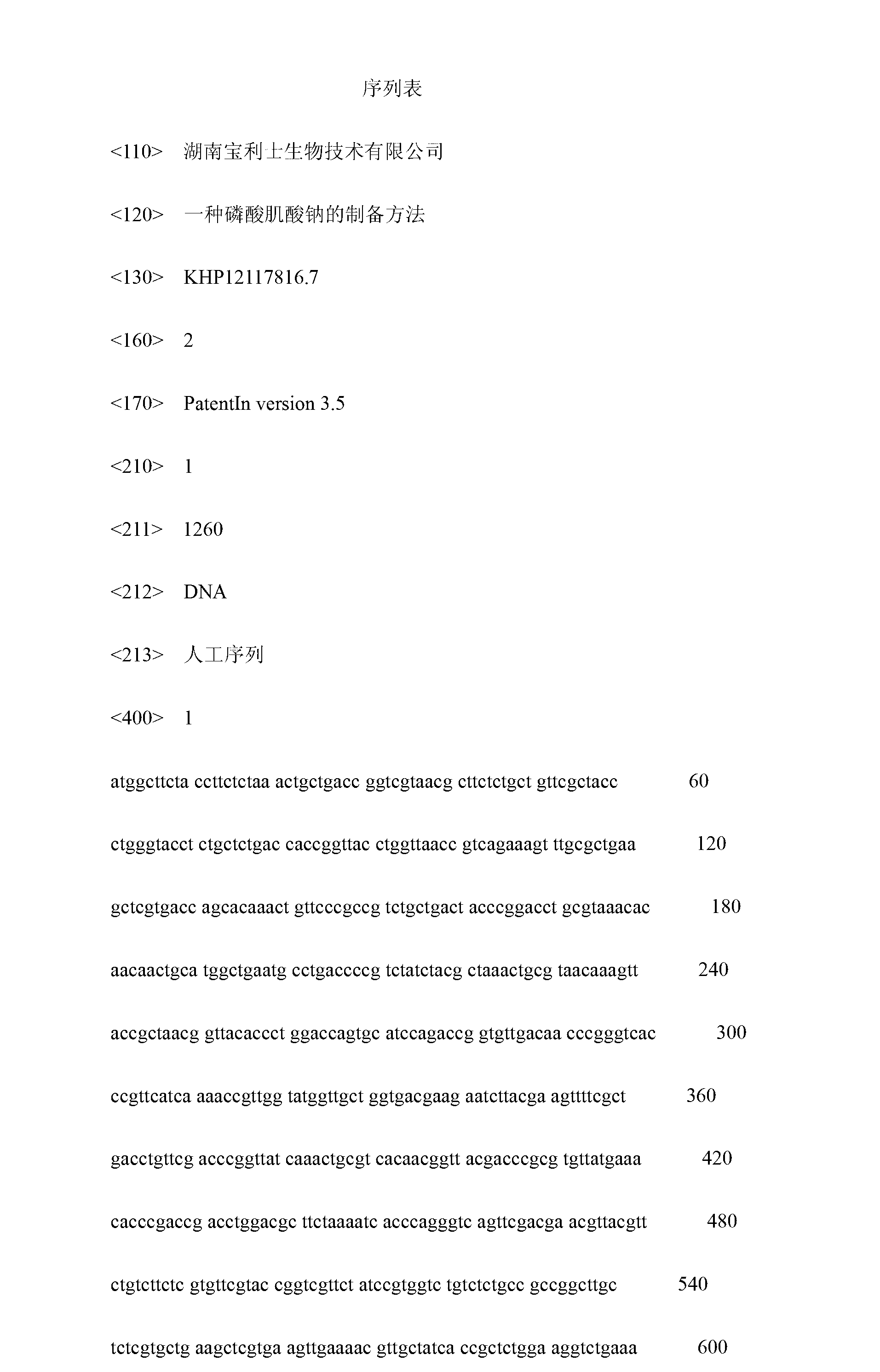

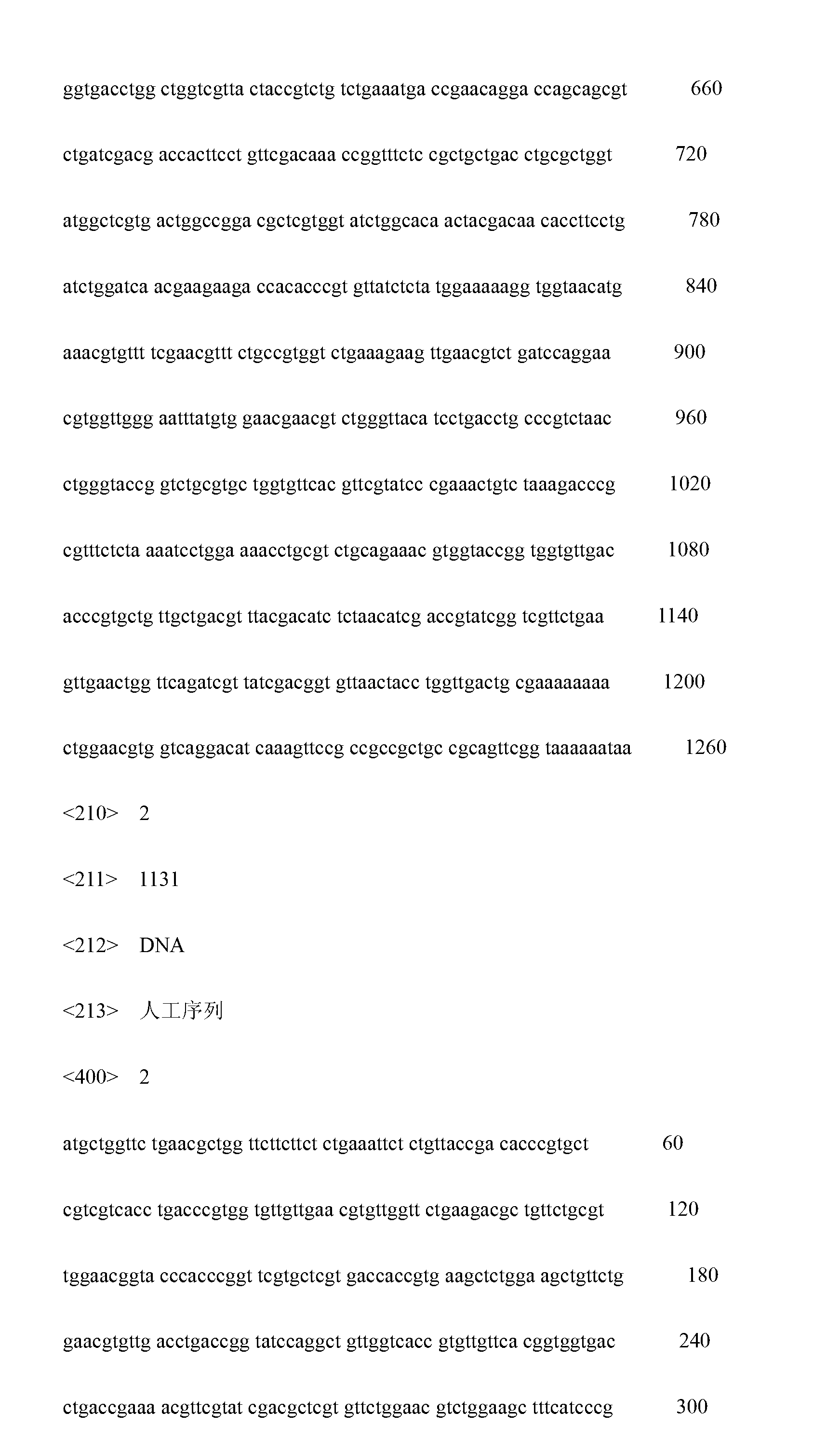

[0061] (1) Chemically synthesize creatine kinase gene (ck-mm) and acetate kinase gene (ak): the nucleotide sequence of the creatine kinase gene (ck-mm) is shown in SEQ ID NO.1; the acetic acid The nucleotide sequence of the kinase gene (ak) is shown in SEQ ID NO.2;

[0062] (2) Digest the synthesized ck-mm gene, ak gene and plasmid pBluescriptII SK(-) with EcoRI and XhoI, recover the desired target fragments and connect them separately to obtain the ligated products, and transform the ligated products into Escherichia coli For Top10 competent cells, pick positive clones to extract recombinant plasmids, sequence and identify them, and obtain recombinant plasmids pBluescriptII SK(-)-ck-mm and pBluescriptII SK(-)-ak;

[0063] (3) Digest recombinant plasmids pBluescriptII SK(-)-ck-mm and pBluescriptII SK(-)-ak and expression vector pET28a(...

Embodiment 2

[0086] (1) Construct the expression strains of creatine kinase and acetate kinase respectively, and the steps of inducing expression and crushing treatment are the same as in Example 1.

[0087] (2) Preparation of high-purity creatine kinase and acetate kinase by specific metal chelation affinity purification method

[0088] Utilize the method of specific metal chelate affinity chromatography to purify the homogenized and broken Escherichia coli recombinant bacterial liquid, the chromatographic filler of the affinity chromatography column used is nickel chelated IDA resin, the Escherichia coli recombinant bacterial liquid is 45BV / h Pass through an affinity chromatography column at a pH of 9.0, 1mol / L imidazole solution at a flow rate of 50BV / h, and desalt the eluent by membrane dialysis to obtain purified creatine kinase and acetate kinase.

[0089] (3) Preparation of co-immobilized enzymes

[0090] Mix creatine kinase, acetate kinase and epoxy resin particles at a ratio of 5...

Embodiment 3

[0106] (1) Construct the expression strains of creatine kinase and acetate kinase respectively, and the steps of inducing expression and crushing treatment are the same as in Example 1.

[0107] (2) Preparation of high-purity creatine kinase and acetate kinase by specific metal chelation affinity purification method

[0108] Utilize the specific metal chelate affinity chromatography method to purify the Escherichia coli recombinant bacterial liquid of the homogenate broken, the chromatographic filler of the affinity chromatography column used is iron chelation IDA resin, the Escherichia coli recombinant bacterial liquid is 35BV / h Pass through an affinity chromatography column at a flow rate of 40BV / h with pH 8.5, 0.8mol / L imidazole solution, and desalt the eluate by membrane dialysis to obtain purified creatine kinase and acetate kinase .

[0109] (3) Preparation of co-immobilized enzymes

[0110] Mix creatine kinase, acetate kinase and epoxy resin particles at a ratio of 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com