Method for preparing quasi-periodic micro-lens arrays through femtosecond laser wet etching

A microlens array and femtosecond laser technology, which is applied in laser welding equipment, lenses, optics, etc., can solve the problems of limited production efficiency of microlens array, influence on uniform light quality, low laser damage threshold, etc., and achieve elimination of periodic light field The effect of coupling superposition effect, high efficiency of processing technology and advantages of light uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

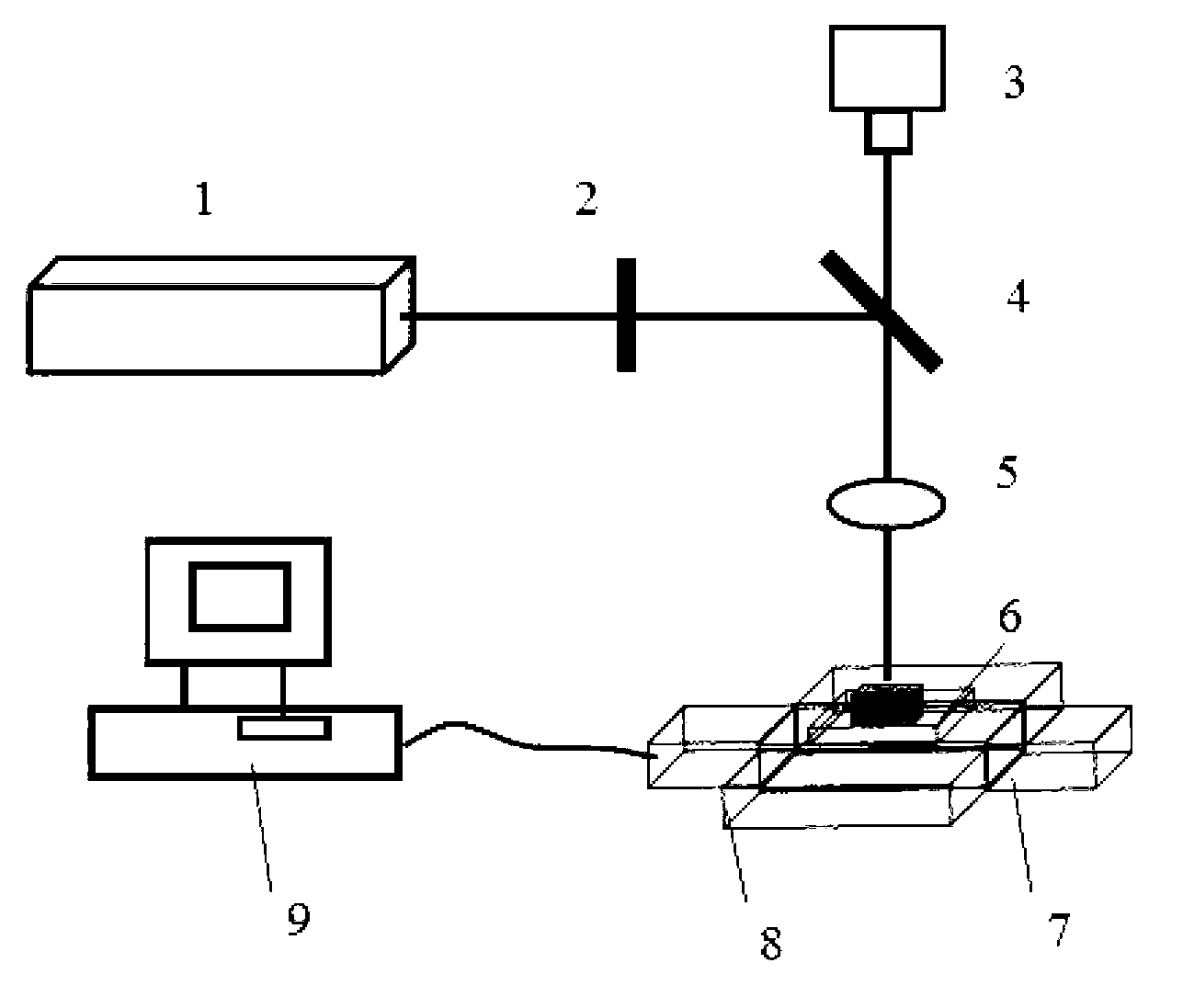

[0030] A method for preparing a quasi-periodic microlens array by femtosecond laser wet etching, comprising the following steps:

[0031] Step 1. Select the hard material used as the femtosecond laser target, put it into three solutions of acetone, ethanol, and deionized water in order to clean thoroughly, then place the target on the femtosecond laser micro-nano processing device, and select the pulse An ultrashort pulse laser with a width of 30fs, a frequency of 1kHz, and a wavelength of 800nm is focused on the surface of a hard material through an objective lens with a numerical aperture of 0.5;

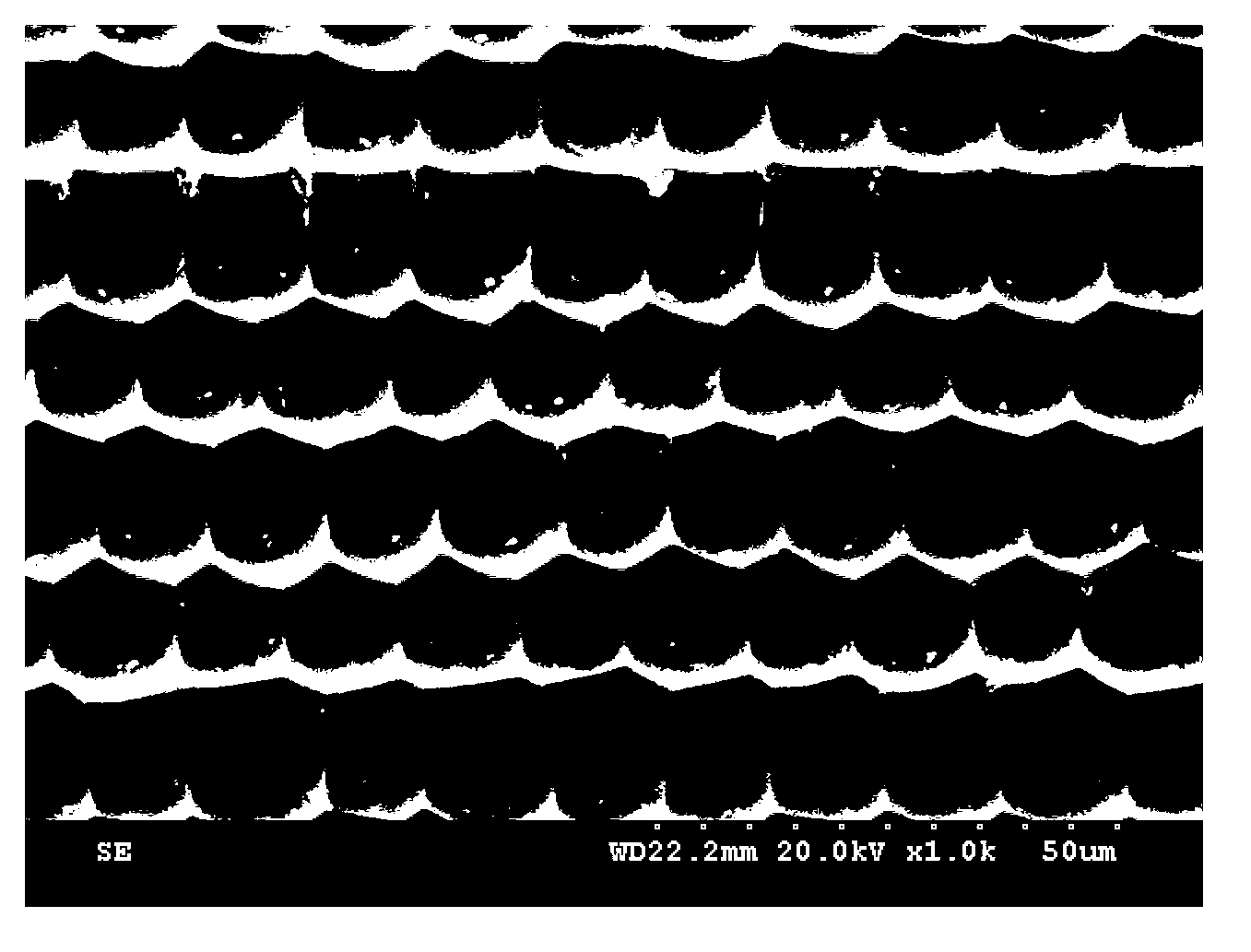

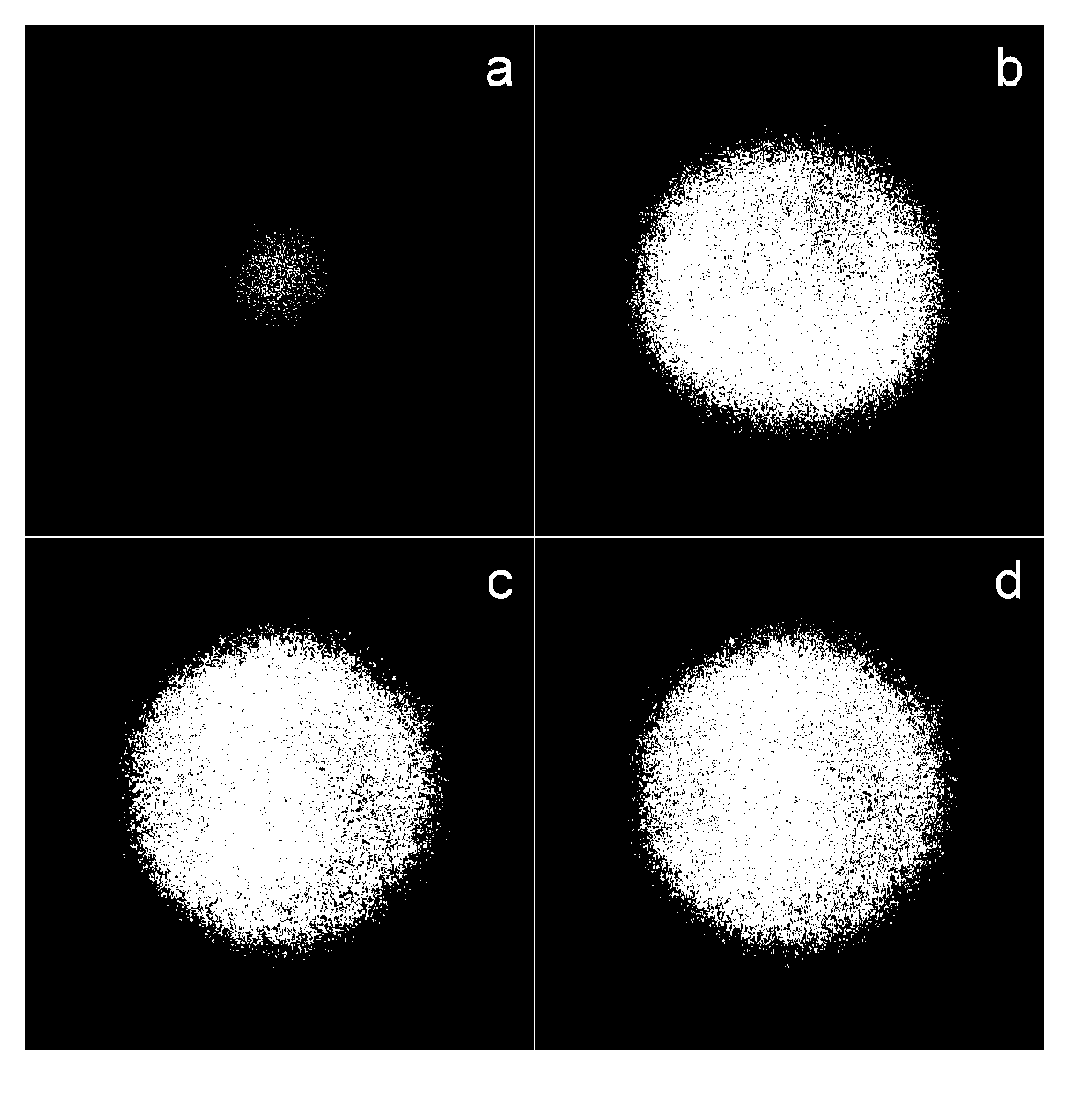

[0032] Step 2. According to the individual average size of the irregular quasi-periodic microlenses to be processed, set the speed at which the precision processing platform drives the target to move, so that the femtosecond laser acts on the surface of the target with one pulse at intervals. Due to the special processing characteristics of the laser, a photodestructive zone wil...

Embodiment 2

[0038] A method for preparing a quasi-periodic microlens array by femtosecond laser wet etching, comprising the following steps:

[0039]Step 1. Select the hard material used as the femtosecond laser target, put it into three solutions of acetone, ethanol, and deionized water in order to clean thoroughly, then place the target on the femtosecond laser micro-nano processing device, and select the pulse An ultrashort pulse laser with a width of 30fs, a frequency of 1kHz, and a wavelength of 800nm is focused on the surface of the hard material through an objective lens with a numerical aperture of 0.45;

[0040] Step 2. According to the individual average size of the irregular quasi-periodic microlenses to be processed, set the speed at which the precision processing platform drives the target to move, so that the femtosecond laser acts on the surface of the target with one pulse at intervals. Due to the special processing characteristics of the laser, a photodestructive zone w...

Embodiment 3

[0045] A method for preparing a quasi-periodic microlens array by femtosecond laser wet etching, comprising the following steps:

[0046] Step 1. Select the hard material used as the femtosecond laser target, put it into three solutions of acetone, ethanol, and deionized water in order to clean thoroughly, then place the target on the femtosecond laser micro-nano processing device, and select the pulse An ultrashort pulse laser with a width of 30fs, a frequency of 1kHz, and a wavelength of 800nm is focused on the surface of the hard material through an objective lens with a numerical aperture of 0.5;

[0047] Step 2. According to the individual average size of the irregular quasi-periodic microlenses to be processed, set the speed at which the precision processing platform drives the target to move, so that the femtosecond laser acts on the surface of the target with one pulse at intervals. Due to the special processing characteristics of the laser, a photodestructive zone w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com