Device for producing dry-mixed coating mortar with controllable whiteness and application thereof

A technology for facing mortar and mixing device, which is applied in cement mixing device, clay preparation device, chemical instrument and method, etc., can solve the problems of poor color management, poor color chromaticity, and high requirements for color uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

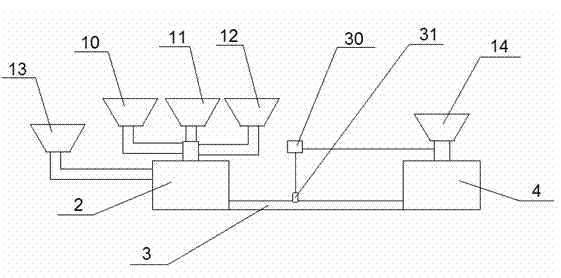

[0072] The basic components of mortar include cement, redispersible latex powder, powdery calcium carbonate, and water reducing agent. According to the weight ratio in Table 1, the gel material metering device 10 weighs 20kg of cement and 6kg of redispersible latex powder and filler Measuring device 11 weighs 66.5kg of calcium carbonate (300 mesh particle size), additive metering device 12 weighs 0.5kg of water reducer, aggregate metering device 13 weighs 7kg of quartz sand (particle size 3mm), and sends it to the first Mixing device 2 performs mixing.

[0073] Table 1, the weight ratio of mortar base components and aggregate materials in Example 1 (unit: kg)

[0074] materials Portland cement Redispersible latex powder calcium carbonate Polycarboxylate superplasticizer Quartz sand weight 20 6 66.5 0.5 7

[0075] The obtained mixture is sent into the second mixing device 4 through the first material conveying system 3, and a whiteness detecti...

Embodiment 2

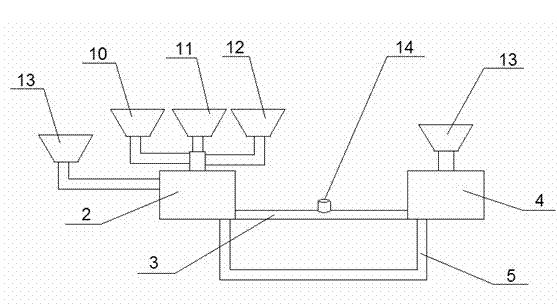

[0079] The basic components include cement, redispersible latex powder, powdered calcium carbonate, and water reducer. According to the weight ratio in Table 2, the gel material metering device 10 weighs 20kg of cement and 6kg of redispersible latex powder and fillers. Equipment 11 weighs 66.5kg of calcium carbonate (particle size 300 mesh), additive metering equipment 12 weighs 0.5kg of water reducer, aggregate metering device 13 weighs 7kg of quartz sand (particle size 3mm), and sends them into the first mixing Apparatus 2 for mixing.

[0080] Table 2, the weight ratio of mortar base components and aggregate materials in Example 2 (unit: kg)

[0081] materials Portland cement Redispersible latex powder calcium carbonate Polycarboxylate superplasticizer Quartz sand weight 20 6 66.5 0.5 7

[0082] The obtained mixture is sent into the second mixing device 4 through the first material conveying system 3, and a sampling port 32 is set in the firs...

Embodiment 3

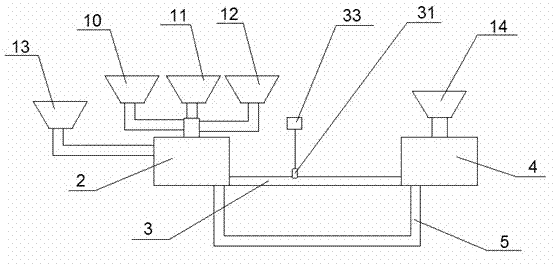

[0086] The basic components include cement, redispersible latex powder, powdered calcium carbonate, and water reducer. According to the weight ratio in Table 3, the gel material metering device 10 weighs 20kg of cement and 6kg of redispersible latex powder, and fillers are measured. Equipment 11 weighs 66.5kg of calcium carbonate (particle size 300 mesh), additive metering equipment 12 weighs 0.5kg of water reducer, aggregate metering device 13 weighs 7kg of quartz sand (particle size 3mm), and sends them into the first mixing Apparatus 2 for mixing.

[0087] Table 3, the weight ratio of mortar base components and aggregate materials in Example 3 (unit: kg)

[0088] materials Portland cement Redispersible latex powder calcium carbonate Polycarboxylate superplasticizer Quartz sand weight 20 6 66.5 0.5 7

[0089] The obtained mixture is sent into the second mixing device 4 through the first material conveying system 3, and a sampling port 32 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com