Mildew proof antibacterial material with bionic micrometer structure surface and preparation method thereof

An anti-mildew, antibacterial, micro-structure technology, applied in micro-structure devices without moving elements, processes for producing decorative surface effects, micro-structure technology, etc. To achieve strong anti-mildew antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

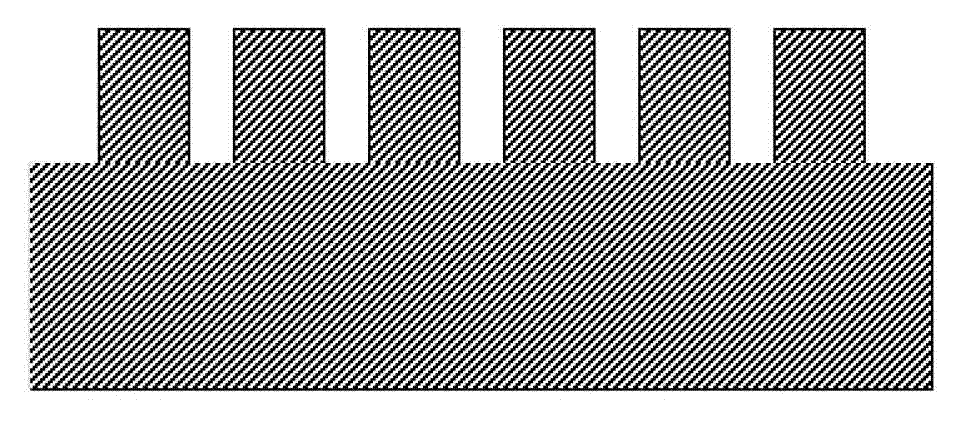

[0048] Plate making:

[0049] The surface topology of the present invention was transferred to a relief nickel master plate, and then 5 intaglio sub-plates were prepared by electroplating for imprinting. The sub-plate has a width of 880 mm and a length of 330 mm, and is tensioned on the surface of the plate roller through a locking device. Each sub-plate can press 30,000 meters of PET polyester anti-mildew and anti-bacterial film.

[0050] UV imprinting:

[0051] Materials: 25 micron thick PET polyester film, DYMAX Ultra Light-Weld ? 4-20638

[0052] Low viscosity UV curable adhesive with a viscosity of 65 cps.

[0053] Process flow and parameters:

[0054] Such as Figure 7 As shown: A roll of 5000 meters long and 1 meter wide PET polyester film with a thickness of 25 microns is placed on the unwinding roller 1 and connected to the winding roller 9 through the path shown in the figure.

[0055] Adjust the heating device 3 to make the temperature in the heating channel...

Embodiment 2

[0064] Plate making:

[0065] The surface topology was transferred to the letterpress nickel master, and then 10 intaglio sub-plates were prepared by electroplating for imprinting. The sub-plate has a width of 880 mm and a length of 330 mm, and is tensioned on the surface of the plate roller through a locking device. Each sub-plate can press 10,000 meters of BOPP polypropylene anti-mildew and anti-bacterial film.

[0066] Material: PET polyester film of 100 micron thickness.

[0067] Process flow and parameters:

[0068] Such as Figure 8 As shown, a roll of 2500 meters long and 1 meter wide 100 micron thick BOPP polypropylene film is placed on the unwinding roller 21 and connected to the winding roller 26 through the path shown in the figure. Adjust the power of the heating roller 22, the temperature of the BOPP polypropylene film is stable at 50±1 oC, (the glass transition temperature is 60 oC); adjust the heating power of the plate roller 3, so that the temperature of t...

Embodiment 3

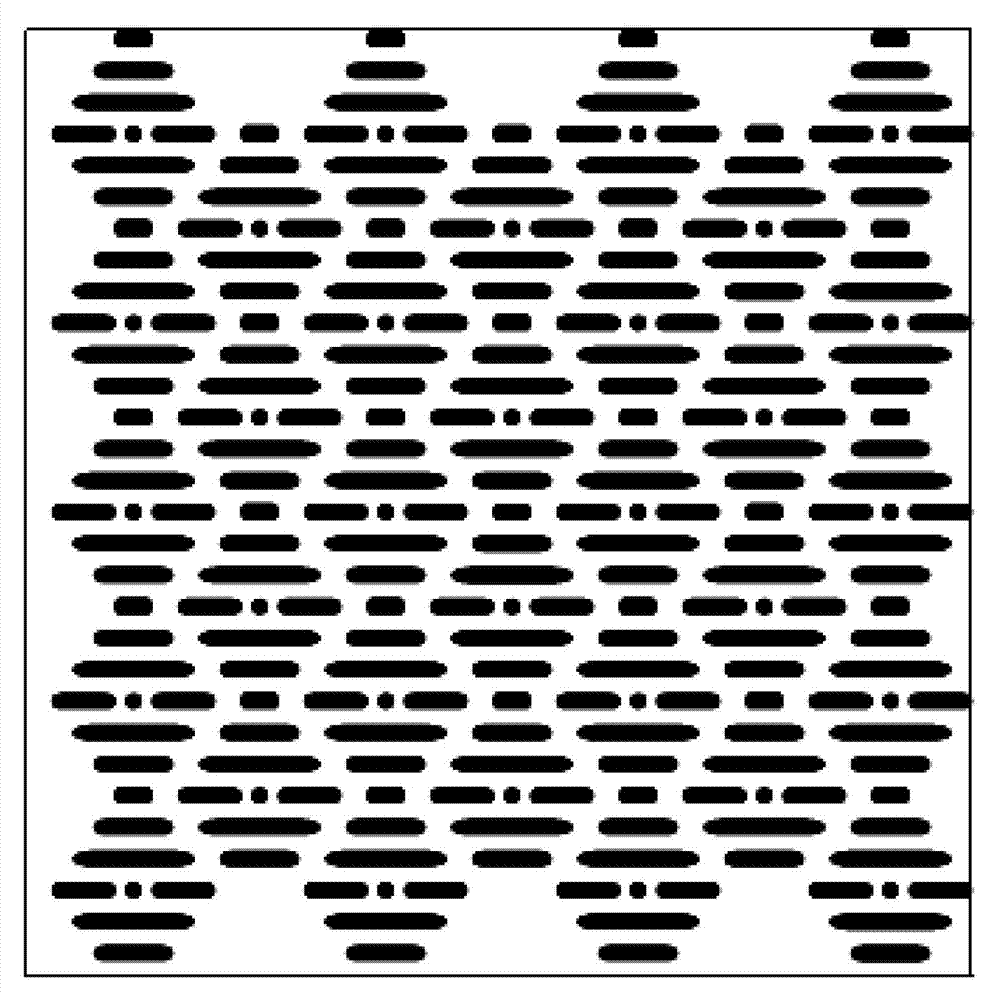

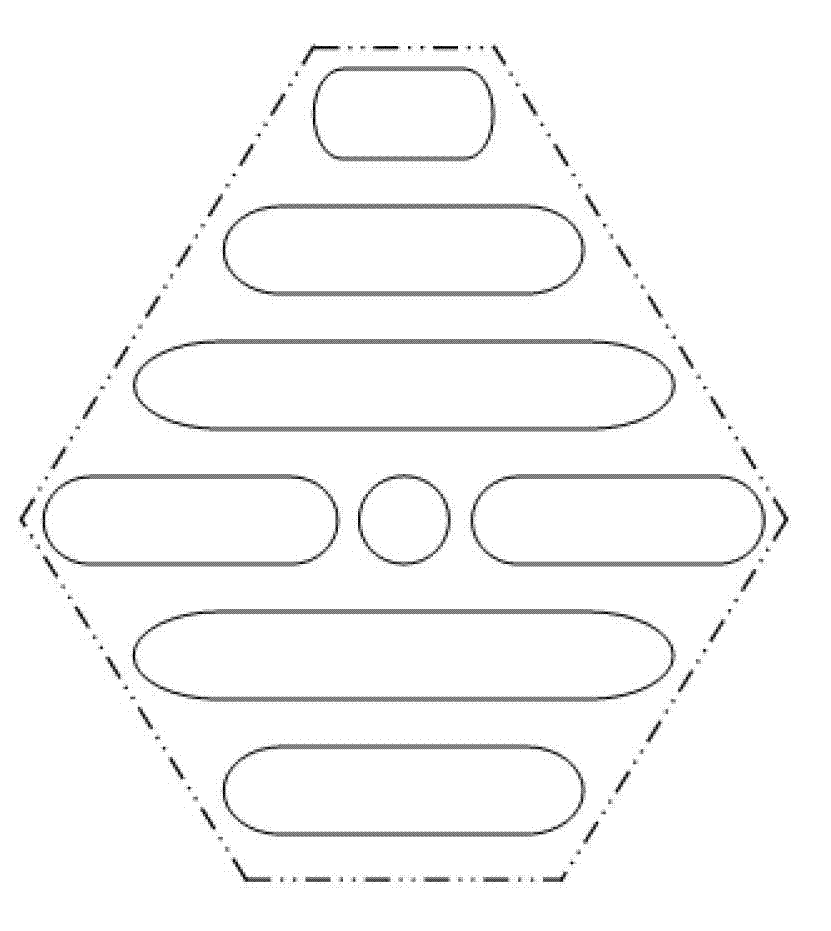

[0070] Will Figure 5 The three surface topologies of FTD-6, SK-6, and EL-6 are shown in the drawing program to generate planar repeating patterns, and the silicon wafer master is prepared by the existing photolithography technology. Then place the silicon wafer master in a 50:1 H2SO4:H2O2 solution and heat it to 120 oC for 10 minutes. After taking it out, wash it with acetone and ethanol three times respectively, and dry it with nitrogen.

[0071] Then place the silicon wafer master in 10% (volume concentration) hexamethyldisilazane solution for 10 minutes to make the surface repeat methylation to reduce the adhesion to polydimethylsiloxane (PDMS) effect. After removal, repeat the acetone and ethanol washing steps.

[0072] Insert the silicon wafer master into the glass mold, inject polydimethylsiloxane (PDMS) pre-polymerization liquid, and take out the fully cured PDMS film after curing at room temperature for 1 hour. The thickness is 2 mm, and the surface has been transf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com