High-strength efficient cement-based light transmission material and preparation method thereof

A light-transmitting material, cement-based technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems affecting the durability, light transmission and appearance of cement-based light-transmitting materials, affecting the appearance and durability of cement-based light-transmitting materials, Cement-based light-transmitting materials are limited in the scope of use, to achieve the effects of good air stability, improved strength and ornamental, and good environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A high-strength and high-efficiency cement-based light-transmitting material, which includes 1000g of light-burned magnesium oxide with an active content of 65%, 1120g of an aqueous solution of magnesium chloride with a mass concentration of 26.8%, 50g of silica fume, 100g of wood powder, and a plastic transparent material with a diameter of 2mm. Optical fiber, the dosage of light-transmitting fiber is 22%, polydimethylsiloxane defoamer 5g, polyvinyl alcohol micropowder 100g, mass concentration is 1g of phosphoric acid of 85%, ferrous sulfate 5g.

[0048] The preparation method of the above-mentioned high-strength and high-efficiency cement-based light-transmitting material specifically includes the following implementation steps:

[0049] (1) Prepare raw materials: prepare raw materials according to the above ratio, and set aside;

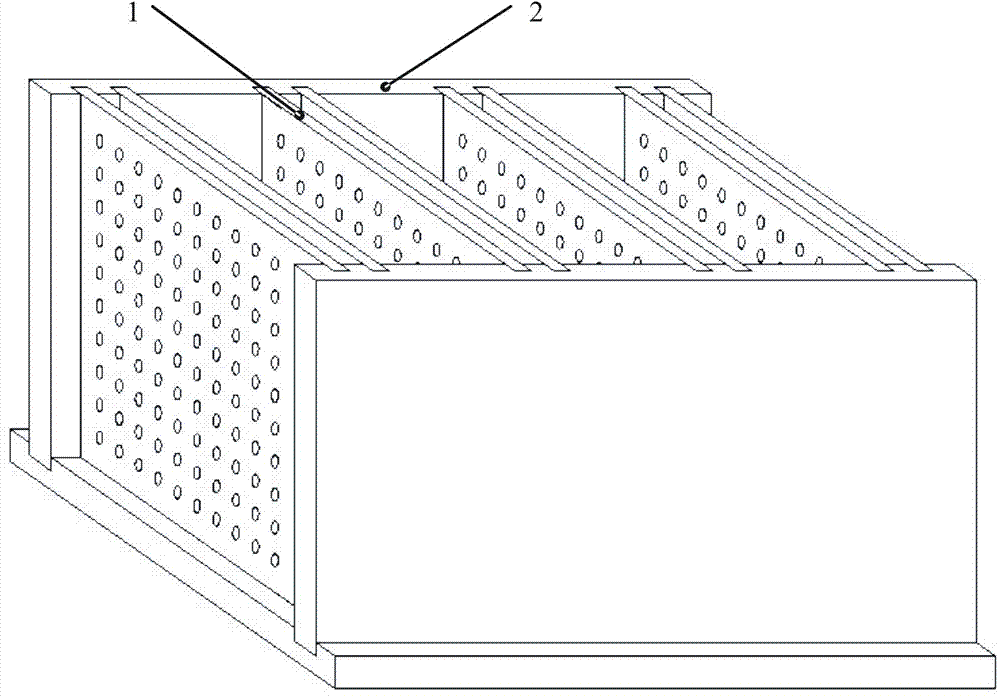

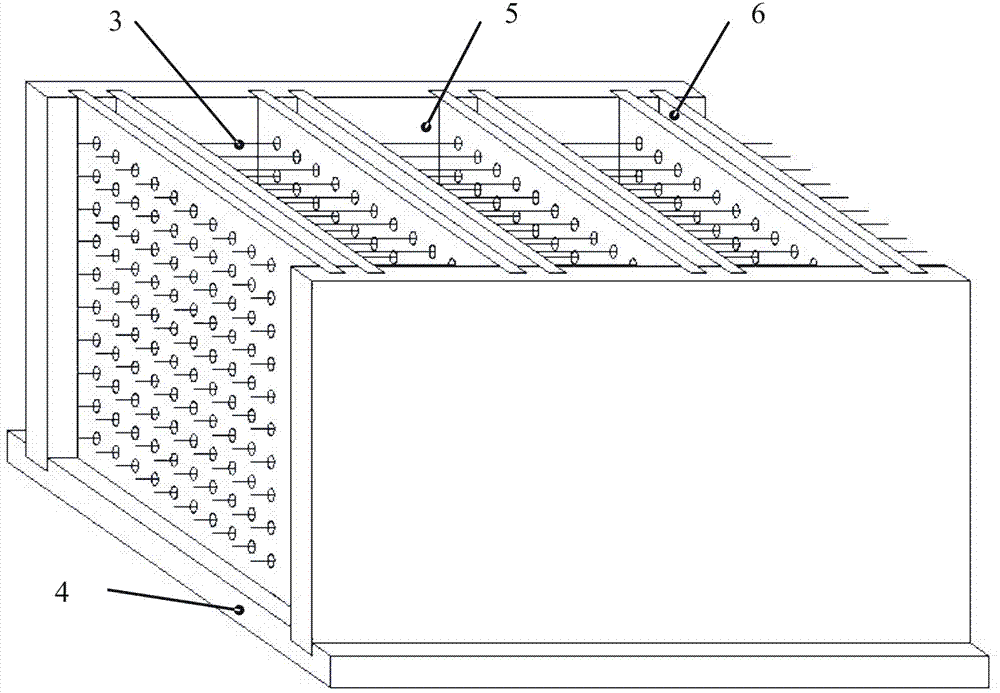

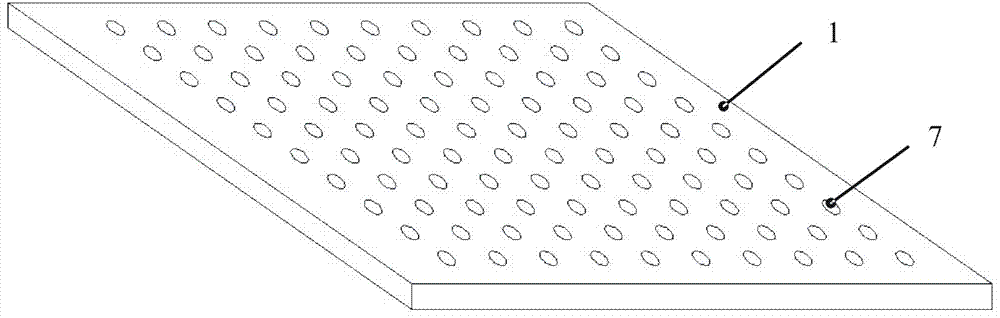

[0050] (2) Preparation of the fixing frame:

[0051] Choose the mold with holes as the fixing frame. The mold with holes consists of bott...

Embodiment 2

[0062] A high-strength and high-efficiency cement-based light-transmitting material, which includes 1000g of light-burned magnesia with an active content of 60%, 1250g of an aqueous magnesium chloride solution with a mass concentration of 22.7%, 600g of fly ash as an admixture, and a quartz light-transmitting material with a diameter of 1.4mm. Fiber, light-transmitting fiber content is 15%, polyether modified polysiloxane defoamer 1g, polyvinyl alcohol micropowder 50g, mass concentration is 85% phosphoric acid 1g, ferrous sulfate 5g.

[0063] The preparation method of the above-mentioned high-strength and high-efficiency cement-based light-transmitting material specifically includes the following implementation steps:

[0064] (1) Prepare raw materials: prepare raw materials according to the above ratio, and set aside;

[0065] (2) Preparation of the fixing frame:

[0066] Select the same fixing bracket as in Example 1, the difference is that: the diameter of the optical fibe...

Embodiment 3

[0077] A high-strength and high-efficiency cement-based light-transmitting material, which includes 1000g of light-burned magnesium oxide with an active content of 60%, 800g of magnesium chloride aqueous solution with a mass concentration of 27.4%, 100g of admixture sawdust powder, and a plastic light-transmitting fiber with a diameter of 3mm. The dosage of light-transmitting fiber is 25%, polydimethylsiloxane defoamer 10g, polyvinyl alcohol micropowder 50g, mass concentration 85% phosphoric acid 5g, ferrous sulfate 5g.

[0078] The preparation method of the above-mentioned high-strength and high-efficiency cement-based light-transmitting material specifically includes the following implementation steps:

[0079] (1) Prepare raw materials: prepare raw materials according to the above ratio, and set aside;

[0080] (2) Preparation of the fixing frame: choose the same fixing frame as in Example 1, the difference is that: the front and rear templates 2 are also provided with seve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com