Method for preparing organic fertilizer from plant charcoal and wood vinegar

A production method, plant charcoal technology, applied in the direction of fertilization device, fertilizer mixture, application, etc., to achieve the effect of reducing use, preventing reduction in efficacy, and promoting environmental safety requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The plant raw material used in this embodiment is corncob.

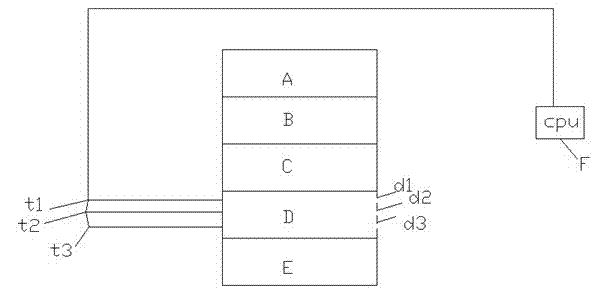

[0035] Put the plant material into the microwave vacuum tank, vacuumize to -0.02MPa, and then conduct microwave treatment, the microwave frequency is 300MHz, and the microwave treatment time is 1min; the plant material obtained after pretreatment is dried and pre-carbonized in sequence , carbonization, calcination and cooling, the temperature of each temperature measurement point, the drying zone A is 150°C, the pre-carbonization zone B is 275°C, and the carbonization zone C is 450°C. figure 1 The zone D shown is the temperature of different positions in the combustion zone. When the temperature of a certain place in the combustion zone, such as d2, is too low, open the small hole in that place, introduce air and burn it nearby, so as to raise the temperature in this place and control the bamboo to move down. The temperature of the combustion zone experienced during the process, control the combustion to raise...

Embodiment 2

[0042] The plant material used in this example is bamboo chips (about 40 cm long).

[0043]Put the plant material into the microwave vacuum tank, vacuumize until the vacuum degree is -0.001MPa, and then carry out microwave treatment, the microwave frequency is 950MHz, and the microwave treatment time is 3min;

[0044] The plant raw materials obtained through pretreatment are dried, pre-carbonized, carbonized, calcined, and cooled in sequence. The temperature at each temperature measurement point is 150°C in drying area A, 275°C in pre-carbonization area B, and 450°C in carbonization area C. The pyrolysis gas produced in the carbonization zone flows countercurrently or cross-flows with the bamboo in the drying zone from bottom to top to dry the bamboo and reach the carbonization temperature. figure 1 The zone D shown is the temperature of different positions in the combustion zone. When the temperature of a certain place in the combustion zone, such as d2, is too low, open the ...

Embodiment 3

[0051] The plant raw material used in this embodiment is pine tree, and the pine tree is first cut after the skin impurities are removed, and the length is controlled to be no more than 15 cm.

[0052] Put the plant raw material into the microwave vacuum tank, evacuate until the vacuum degree is -0.01~-0.005MPa, and then carry out microwave treatment, the microwave frequency is 550MHz, and the microwave treatment time is 1.2-2min;

[0053] The pre-treated plant raw materials are dried, pre-carbonized, carbonized, calcined, and cooled in sequence. The temperature at each temperature measurement point is 180°C in the drying area A, 325°C in the pre-carbonization area B, and 530°C in the carbonization area C. Observation during warming figure 1 The zone D shown is the temperature of different positions in the combustion zone. When the temperature of a certain place in the combustion zone, such as d2, is too low, open the small hole in that place, introduce air and burn it nearby,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com