Method for preparing intermediate used for synthesizing bortezomib

A technology for bortezomib and intermediates, applied in the field of organic chemical synthesis, can solve problems such as difficulty in obtaining high optical purity bortezomib, inability to meet large-scale production requirements, and difficulty in obtaining raw materials, and achieve remarkable effects and economic practicability. , mild reaction conditions, simple post-processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

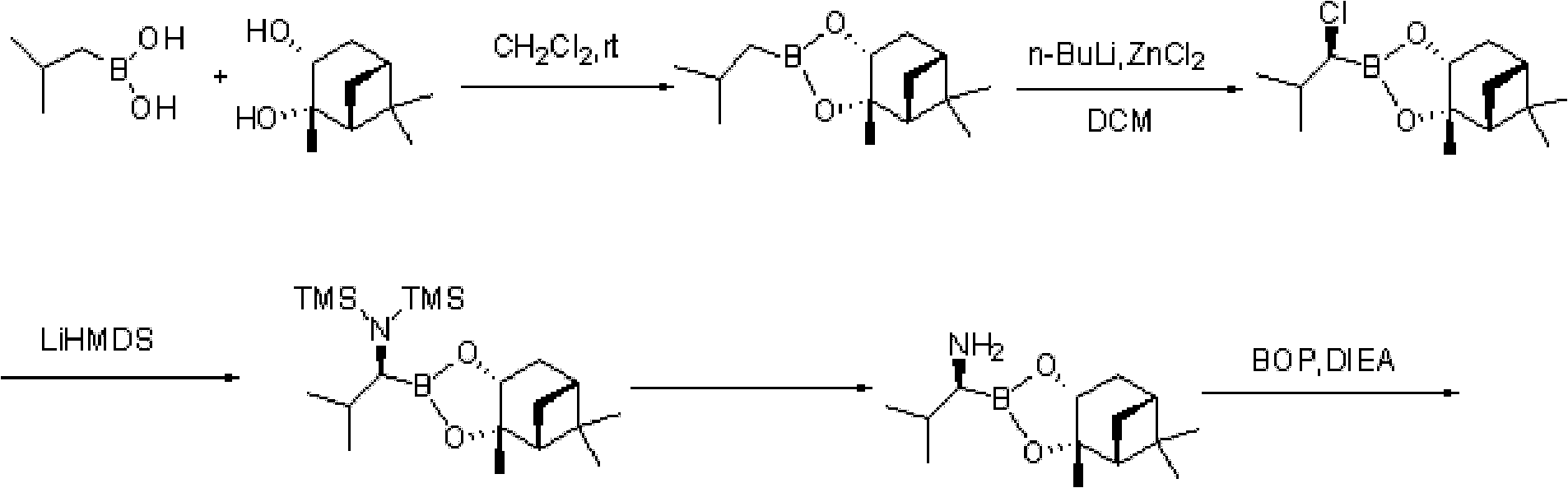

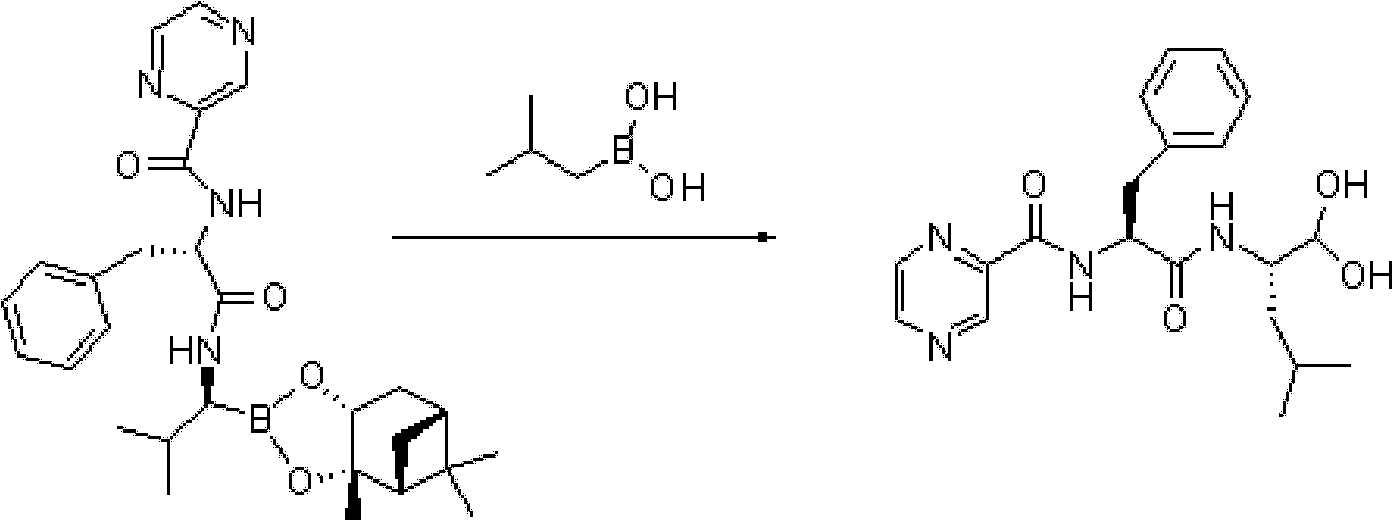

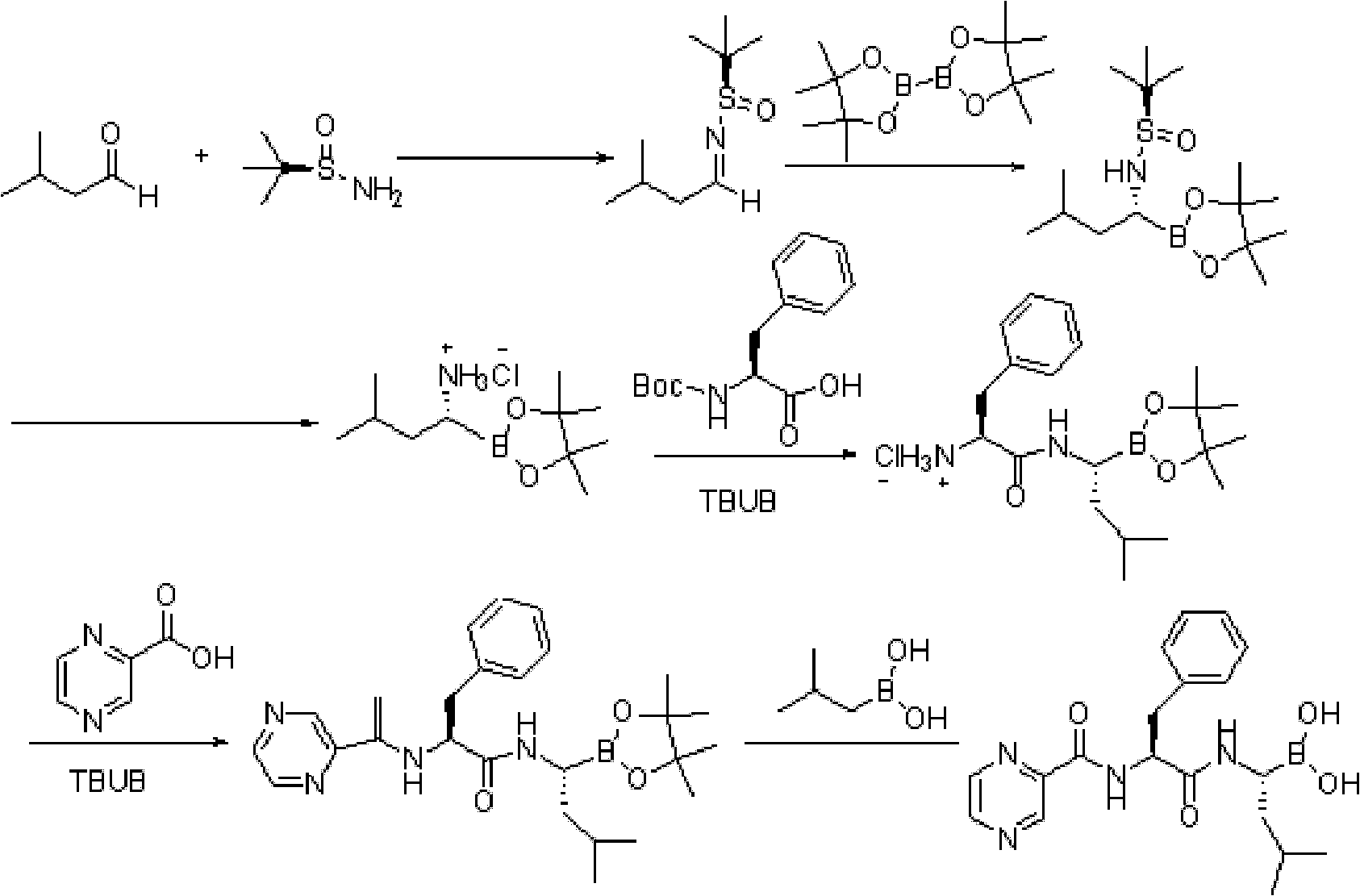

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: Synthesis of (1-hydroxyl-3-methyl) butyl-pinacol borate III

[0036]

[0037] Add 43g (0.5mol) of 3-methylbutyraldehyde I, 2.5g (0.025mol) of cuprous chloride and 254g (1mol) of double pinacol borate II into a 1L four-necked flask, add 750ml of benzene, and reflux After reacting for 4 hours, the solvent was evaporated to dryness under reduced pressure to obtain 100.6 g of oily crude product III with a molar yield of 94%. The product was directly put into the next reaction without purification.

Embodiment 2

[0038] Embodiment 2: Synthesis of (1-hydroxyl-3-methyl) butyl-pinacol borate III

[0039]

[0040] Add 43g (0.5mol) 3-methylbutyraldehyde I, 5g (0.025mol) copper acetate and 381g (1.5mol) double pinacol borate II into a 2L four-necked flask, add 1L dichloromethane, and reflux After reacting for 6 hours, the solvent was evaporated to dryness under reduced pressure to obtain 96.5 g of oily crude product III with a molar yield of 90%, which was directly put into the next reaction without purification.

Embodiment 3

[0041] Embodiment 3: Synthesis of (1-hydroxyl-3-methyl) butyl-pinacol borate III

[0042]

[0043] Add 43g (0.5mol) 3-methylbutyraldehyde I, 3.6g (0.025mol) cuprous bromide and 191g (0.75mol) double pinacol borate II into a 1L four-necked flask, add 600ml of benzene, The reaction was refluxed for 8 hours, and the solvent was evaporated to dryness under reduced pressure to obtain 94 g of oily crude product III with a molar yield of 88%. The product was directly put into the next reaction without purification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com