Hard foam polyurethane phase-transition heat preservation composite board

A technology of rigid foam polyurethane and thermal insulation composite board, which is applied in thermal insulation, building components, buildings, etc., can solve the problems of insufficient recycling of thermal energy, weak ability to absorb and release thermal energy, neglect of energy recycling, etc. The effect of recycling, extending durability, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] According to the rigid foam polyurethane phase change composite board of the present invention, according to the following proportioning:

[0023]

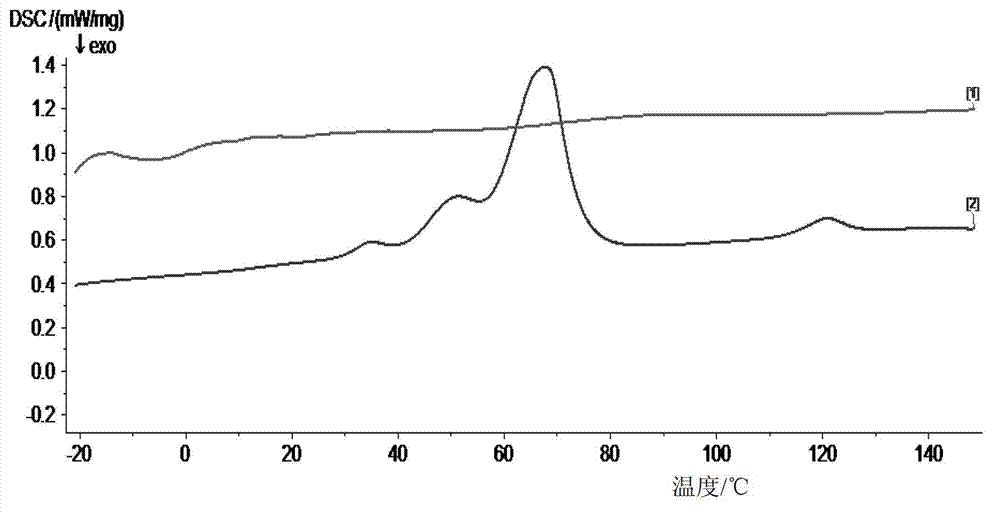

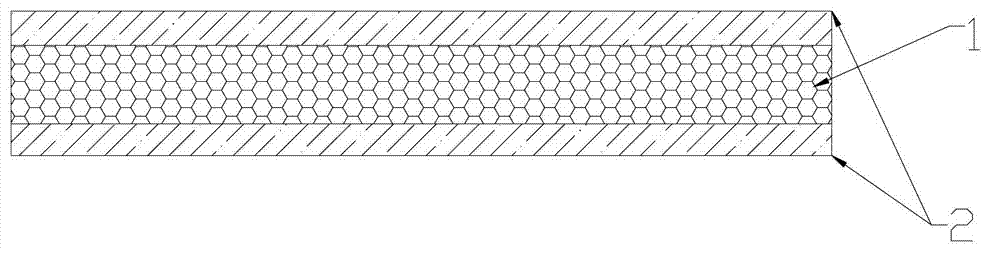

[0024] After the paraffin is heated and emulsified, it is dispersed in the mixture of styrene-acrylic emulsion, cement, quartz powder, river sand, TCEP, and water reducer to form a phase-change glue, and then the phase-change glue is scraped on the glass fiber felt through the coil production line. Drying is made into a phase-change sheet, and then the mixture of polymerized polyisocyanate and polyether polyol is poured on the phase-change sheet according to the ratio on the continuous foaming line to form a rigid polyurethane phase-change composite board. The cross-sectional structure of the obtained rigid polyurethane phase change composite board is as follows: image 3 shown. Among them, the water reducer refers to the admixture that can reduce the mixing water consumption and improve the concrete strength under the ...

Embodiment 2

[0026] According to the rigid foam polyurethane phase-change thermal insulation composite board of the present invention, according to the following proportions:

[0027]

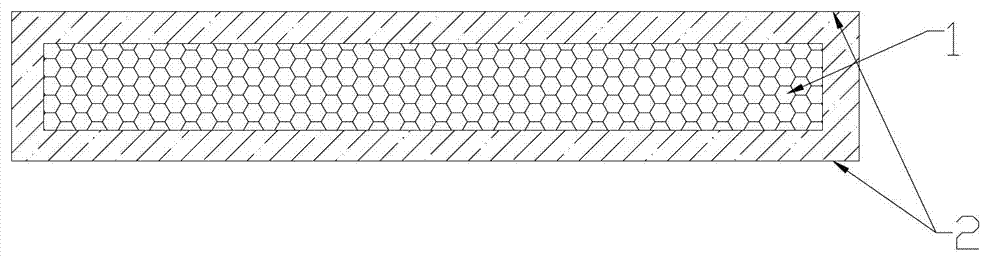

[0028] Polymerized polyisocyanate and combined materials are produced on a continuous foaming line or intermittent mold foaming line according to the ratio to produce a rigid polyurethane foam board, then the paraffin is heated and emulsified to make microcapsules, and then cement, river sand, Quartz powder, VAE redispersible rubber powder, water retaining agent, and polypropylene fiber are mixed in the mortar dry mixer and discharged to make a phase change mortar. Finally, an appropriate amount of water is added to mix with the phase change mortar and then sprayed or scraped on the hard foam. The upper and lower sides of the polyurethane bare board form a rigid foam polyurethane phase-change thermal insulation composite board. The cross-sectional structure of the obtained rigid polyurethane phase change...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com