Enhanced optical microfluidic sensor device coated with dielectric layer and method

A sensing device and enhanced technology, applied in the measurement of phase influence characteristics, etc., can solve the problems of not considering thick-walled microtubes, the limitation of the object to be detected, and limit the applicability of analysis, so as to improve the detection limit, simplify the calibration, reduce the Small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

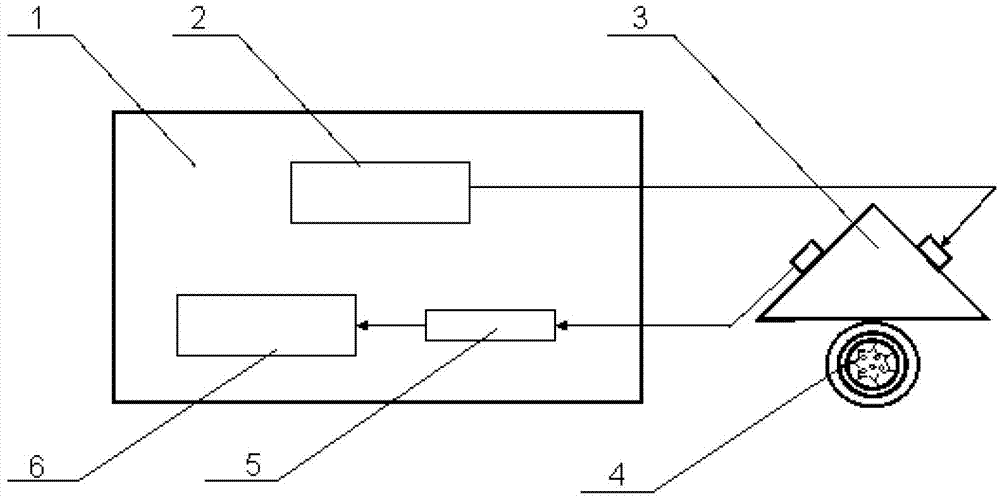

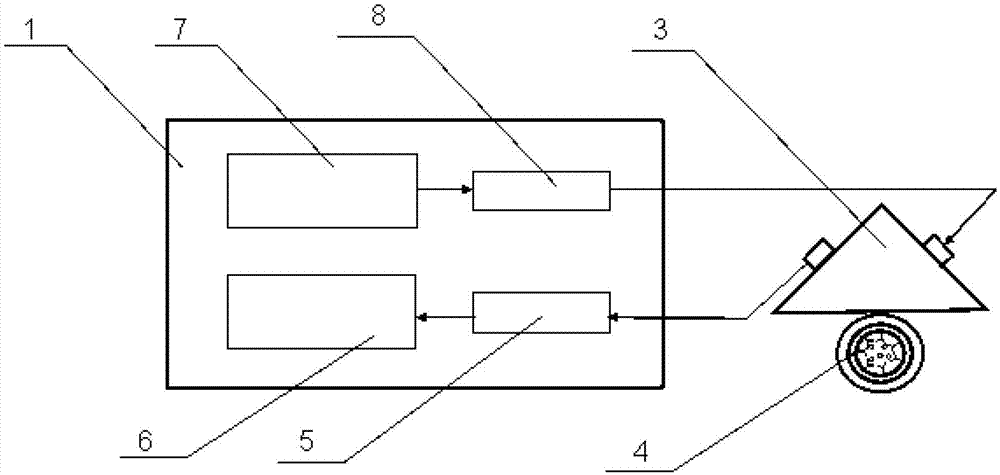

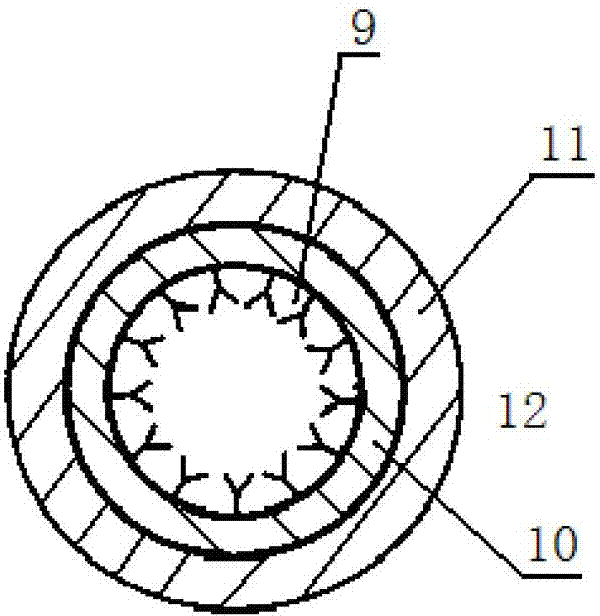

[0041] like figure 1 As shown, an enhanced optical microfluidic sensing device coated with a dielectric layer includes a spectral analysis device 1 , a prism coupling device 3 , and an enhanced optical microfluidic sensor 4 . The spectrum analysis device 1 is composed of a tunable laser 2 , a photodetector 5 and a signal processing unit 6 . The light wave output by the tunable laser 2 is coupled into the enhanced optical microfluidic sensor 4 through the prism coupling device 3, and a WGM resonance mode is formed in the enhanced optical microfluidic sensor, such as image 3 As shown, the biological detection reagent 9 is pre-cured on the inner wall surface of the medium layer 10 with a high refractive index of the enhanced optical microfluidic sensor 4. When the detected biomolecules flow through, the reaction with the biological detection reagent 9 will change the medium layer 10. The refractive index of the inner wall surface and the resonant wavelength of the resonant mode...

Embodiment 2

[0042] Embodiment 2: Fabrication method of an enhanced optical microfluidic sensor coated with a medium layer on the inner surface of the microtube

[0043] Firstly, a quartz tube with an outer diameter of 25 mm and a wall thickness of 4 mm is drawn into a quartz microtube by using an optical fiber drawing tower. The outer diameter of the quartz microtube is 250 μm and the wall thickness is 20 μm; secondly, polystyrene is dissolved in xylene organic solvent , the concentration is 0.1g / ml, then the polystyrene solution is filled into the drawn microtube; finally, the microtube is filled with a hot air flow at 45°C to evaporate the organic solvent, thereby A polystyrene medium layer is formed on the surface of the inner wall of the micropipe, and the thickness of the medium layer is 2.3 μm. It is made into an enhanced optical microfluidic sensor. The refractive index of the polystyrene material in the 1550nm band is 1.59-1.60.

Embodiment 3

[0044] Example 3: An Enhanced Photomicrofluidic Sensing Method Coating a High Refractive Index Medium Layer on the Inner Surface of Microtubes

[0045] like figure 1 , the light emitted by the tunable laser 2 is coupled into the enhanced optical microfluidic sensor 4 through the prism coupling device 3 to generate a WGM resonance mode. The inner surface of the high refractive index medium layer of the enhanced optical microfluidic sensor 4 is pre-cured biological detection reagent 9, and the resonance wavelength of the whispering gallery resonant mode of the enhanced optical microfluidic sensor satisfies

[0046] 2πr eff no eff =2πr eff (n 1 n 1 +n 2 n 2 +n 3 n 3 +n 4 n 4 ) = mλ (1)

[0047] In the formula, r eff is the effective radius, n eff is the effective refractive index, η 1 , η 2 , η 3 , η 4 Respectively, the optical field energy distribution coefficients of the biological detection reagent 9 cured in the tube of the enhanced optical microfluidic sens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com