Metallic oxide material with mesoporous-macroporous composite structure as well as preparation method and application thereof

A composite structure and oxide technology, applied in the direction of material resistance, etc., can solve the problems of low specific surface area of the final product, inability to obtain specific surface area, difficult to use quality, etc., to overcome poor structural order, scientific preparation method, Effect of effect improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The concrete steps of preparation are:

[0032] Step 1, according to the weight ratio between glucose, water and cetyltrimethylammonium bromide is 1:38:0, it is placed in a closed state, and reacted at a temperature of 100°C for 20h, An intermediate product is obtained. The intermediate product is then subjected to centrifugation, washing and drying; wherein, the rotational speed during centrifugation is 2000r / min, the washing treatment is to wash twice with ethanol and deionized water in sequence, and the drying treatment is to dry at 50°C to obtain Carbon spheres with a sphere diameter of 100 nm.

[0033] Step 2, first mix the metal salt, carbon spheres and ethanol according to the ratio of 0.5:0.05:14 by weight, and then sonicate for 10 minutes; wherein, the metal salt is the acetate or metal halide corresponding to the metal oxide to be prepared , the metal salt is now selected as tin dichloride to obtain a mixture. Then the mixture was refluxed at 0° C. for 20 h...

Embodiment 2

[0036] The concrete steps of preparation are:

[0037] Step 1, according to the weight ratio between glucose, water and cetyltrimethylammonium bromide is 5:39:0.1, it is placed in a closed state, and reacted at a temperature of 120 ° C for 15 hours, An intermediate product is obtained. Then the intermediate product was subjected to centrifugation, washing and drying; wherein, the rotational speed during centrifugation was 3000r / min, the washing treatment was washed three times with ethanol and deionized water in sequence, and the drying treatment was dried at 55°C to obtain Carbon spheres with a sphere diameter of 600 nm.

[0038] Step 2, first mix the metal salt, carbon spheres and ethanol according to the ratio of 3:0.1:15 by weight, and then ultrasonicate for 30 minutes; wherein, the metal salt is the acetate or metal halide corresponding to the metal oxide to be prepared , the metal salt is now selected as tin dichloride to obtain a mixture. Then the mixture was refluxe...

Embodiment 3

[0041] The concrete steps of preparation are:

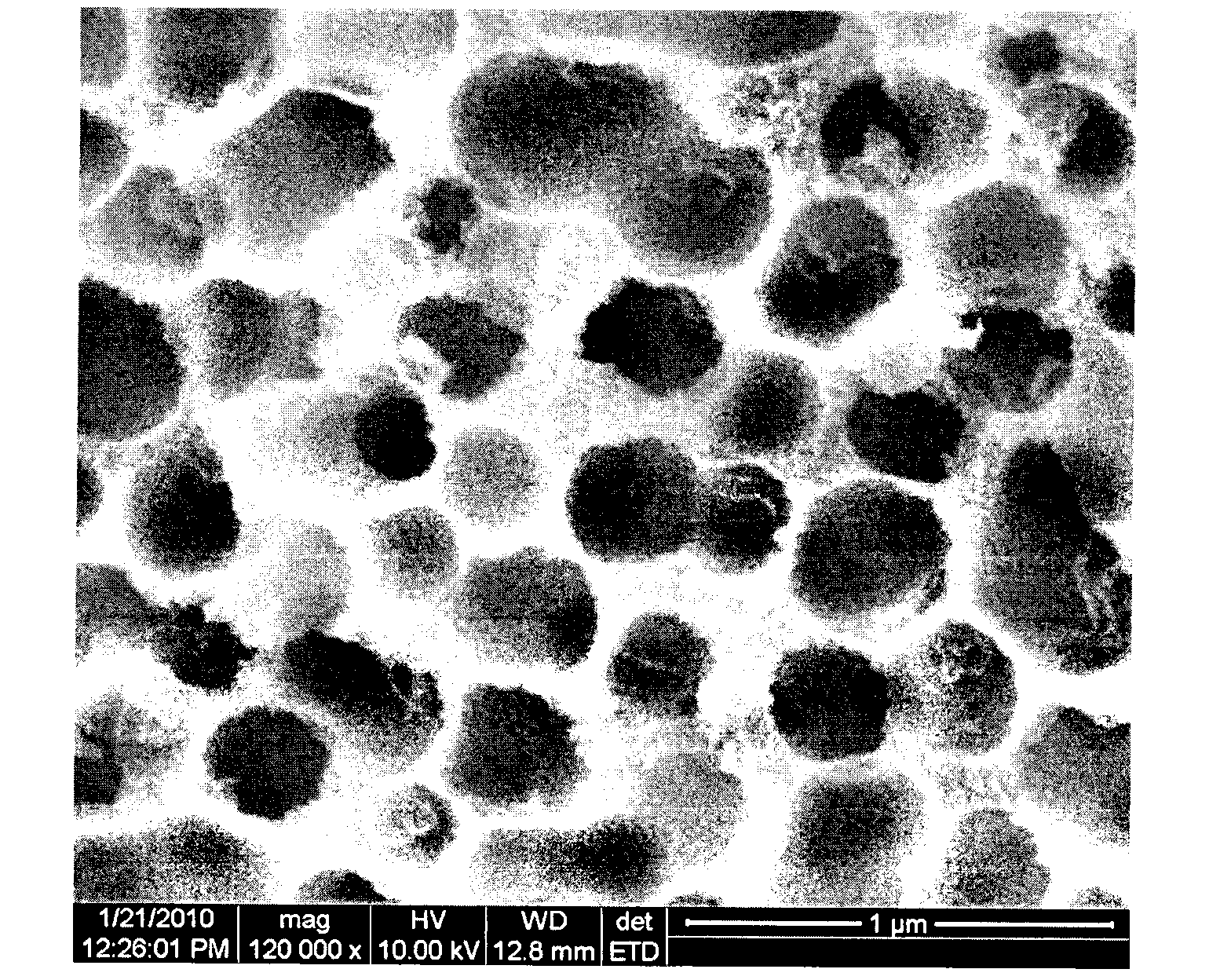

[0042] Step 1, according to the weight ratio between glucose, water and cetyltrimethylammonium bromide is 10:40:0.3, it is placed in a closed state, and reacted at a temperature of 140 ° C for 10 hours, An intermediate product is obtained. Then, the intermediate product was subjected to centrifugation, washing and drying; wherein, the rotational speed during centrifugation was 4000r / min, the washing treatment was washed 4 times with ethanol and deionized water in sequence, and the drying treatment was dried at 60°C to obtain Carbon spheres with a sphere diameter of 1 μm.

[0043] Step 2, first mix the metal salt, carbon spheres and ethanol according to the weight ratio of 5:0.5:16, and then ultrasonicate for 60 minutes; wherein, the metal salt is the acetate or metal halide corresponding to the metal oxide to be prepared , the metal salt is currently selected as tin tetrachloride to obtain a mixture. Then the mixture was reflu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com