Lithium ion battery cathode material compounded with graphene and preparation method thereof

A negative electrode material and ion battery technology, applied in the field of graphene composite lithium ion battery negative electrode material and its preparation, can solve the problems of volume change electrode pulverization, low capacity, etc., achieve easy operation, simple preparation process, increase energy density and The effect of cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

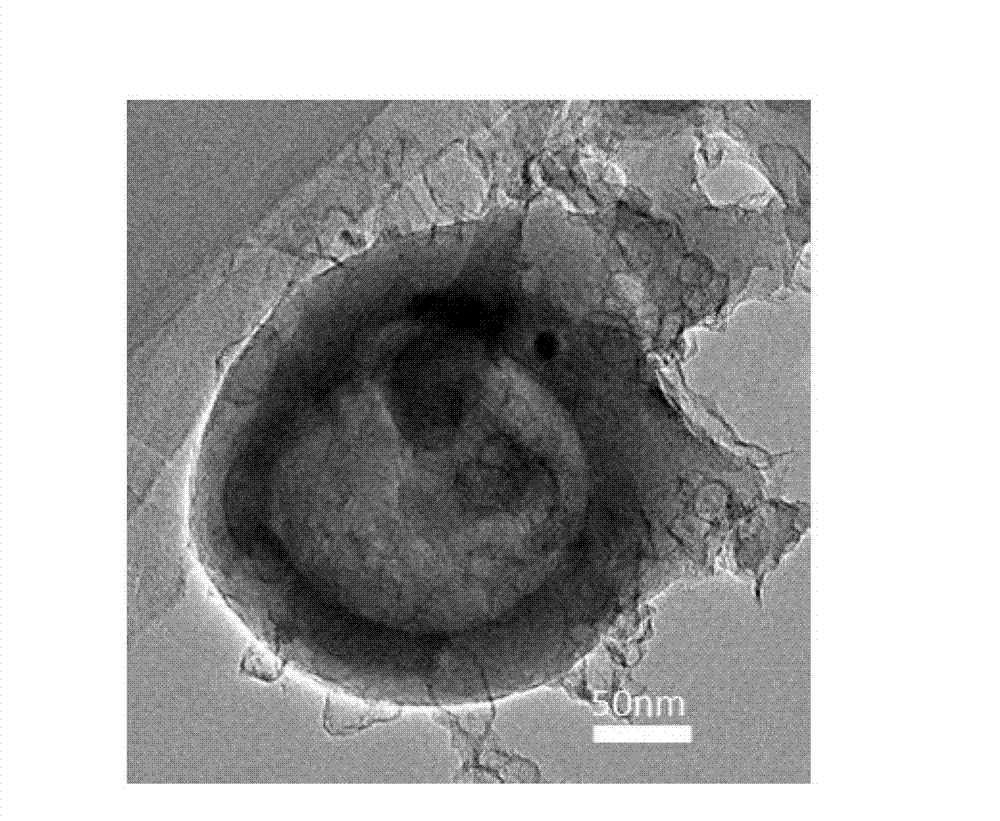

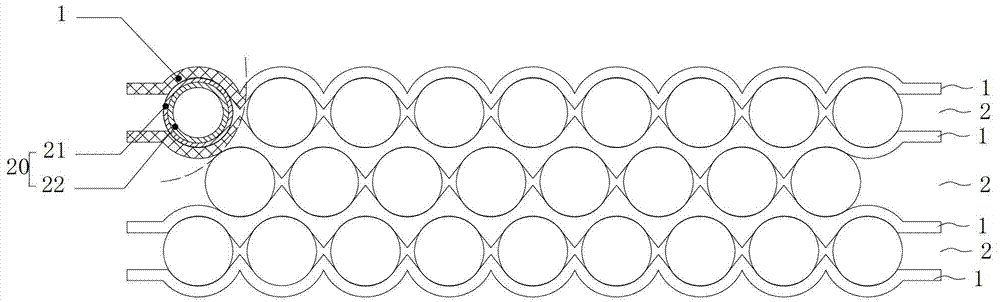

[0031] Such as figure 2 Shown, a kind of composite lithium ion battery negative electrode material, this material comprises multi-layer graphene sheet layer 1, is provided with hollow nanometer negative electrode particle layer 2 between adjacent graphene sheet layer 1, the whole composite lithium ion battery negative electrode The material is a sandwich lamellar structure. The graphene sheet 1 separates the hollow nano-anode particles 20 in the hollow nano-anode particle layer 2 one by one and a half, leaving a gap between the adjacent graphene sheets 1; the hollow nanometer The negative electrode particle 20 is a two-layer hollow structure composed of a carbon outer layer 21 and a hollow metal negative electrode material inner layer 22 .

[0032]In the anode material of the present invention, the hollow nano-anode particle layer 2 is composed of a large number of hollow nano-anode particles 20, and these hollow nano-anode particles 20 are tiled to form a hollow nano-anode ...

Embodiment 2

[0039] A preparation method of composite lithium ion battery negative electrode material, comprising the following steps:

[0040] (1) Mix and react the organic precursor of raw material silica, cationic surfactant, tin salt solution, and organic carbon source; then add graphene oxide or graphene dispersion to continue the reaction; finally dry to obtain the intermediate product; The parts by weight of raw materials are: organic precursor of silicon dioxide 1-20, cationic surfactant 2-10, tin salt 5-50, organic carbon source 5-50, graphene oxide or graphene 1-10;

[0041] (2) The intermediate product is treated with a treatment liquid, and then washed and dried to obtain the primary product; the primary product is heat-treated in an environment with an oxidizing gas content of less than 0.01%, to obtain a negative electrode material for a composite lithium-ion battery.

[0042] In the preparation method of the negative electrode material of the composite lithium ion battery, t...

Embodiment 2-1

[0053] A preparation method of composite lithium ion battery negative electrode material, comprising the following steps:

[0054] (1) Add 30ml of absolute ethanol and 120ml of deionized water into a beaker as a solvent, stir evenly, add 10ml of concentrated ammonia water and 2.4g of cetyltrimethylammonium bromide, and then add 1ml of ethyl orthosilicate Carefully add it dropwise into the beaker, then add 5g of tin protochloride into the beaker, stir evenly to make it all dissolve. Stir mechanically at room temperature for 12 hours, then add 5 g of glucose, continue stirring for 12 hours, and add the reaction solution dropwise to 200 ml of graphene oxide solution with a concentration of 2 mg / ml ultrasonic dispersion, stir for 12 hours, and evaporate to dryness in a water bath at 80 ° C to obtain intermediate product.

[0055] (2) The intermediate product was soaked in HF solution with a concentration of 10% by mass for 60 minutes. After soaking, it was washed with deionized w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inverse capacity | aaaaa | aaaaa |

| Inverse capacity | aaaaa | aaaaa |

| Inverse capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com