NaA molecular sieve membrane element internal membrane preparation method

A molecular sieve and membrane element technology, applied in the field of molecular sieve membrane preparation, can solve the problems of uneven coating and batch difference of molecular sieve membrane, and achieve the effects of high permeation flux, simple method and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

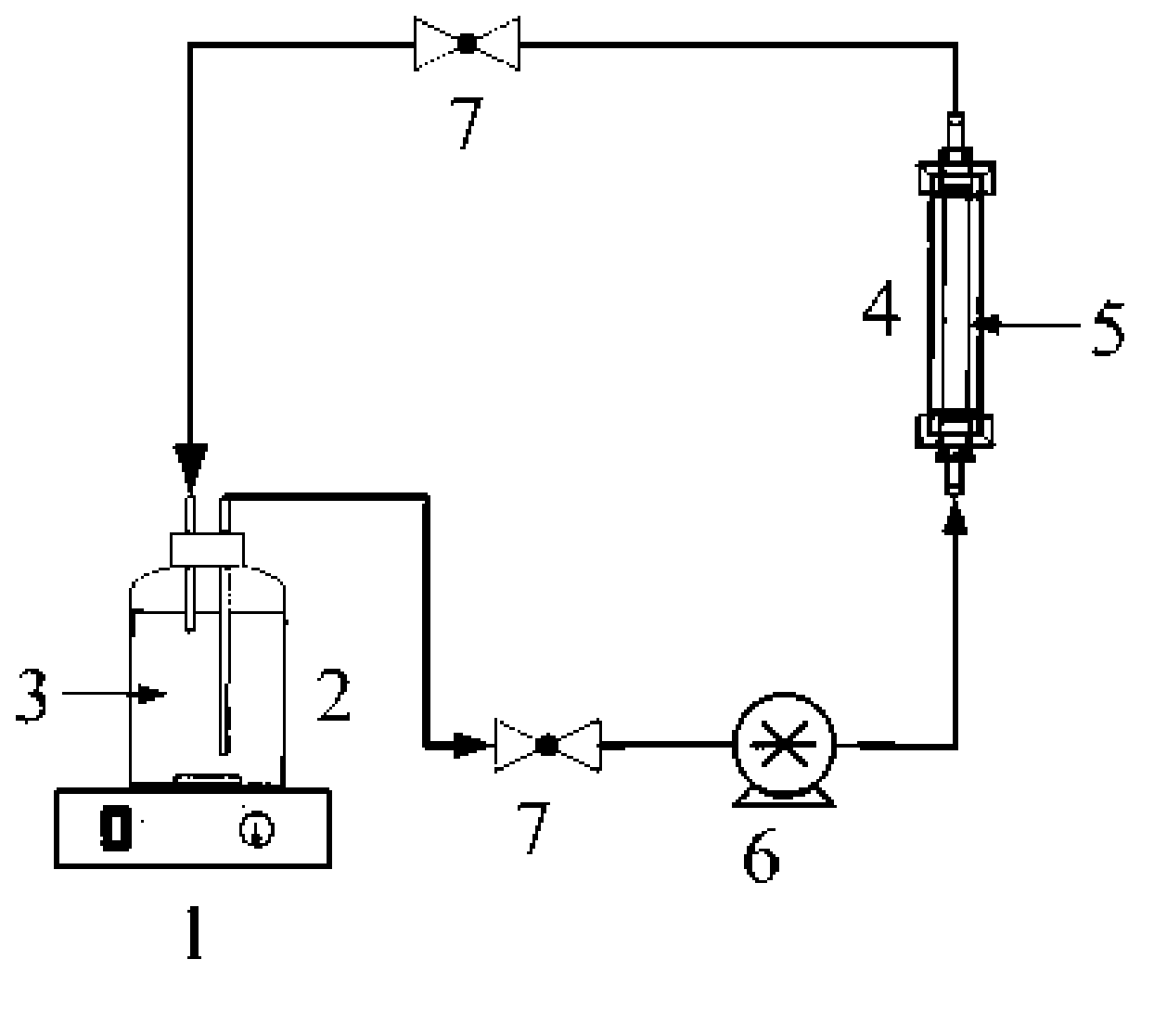

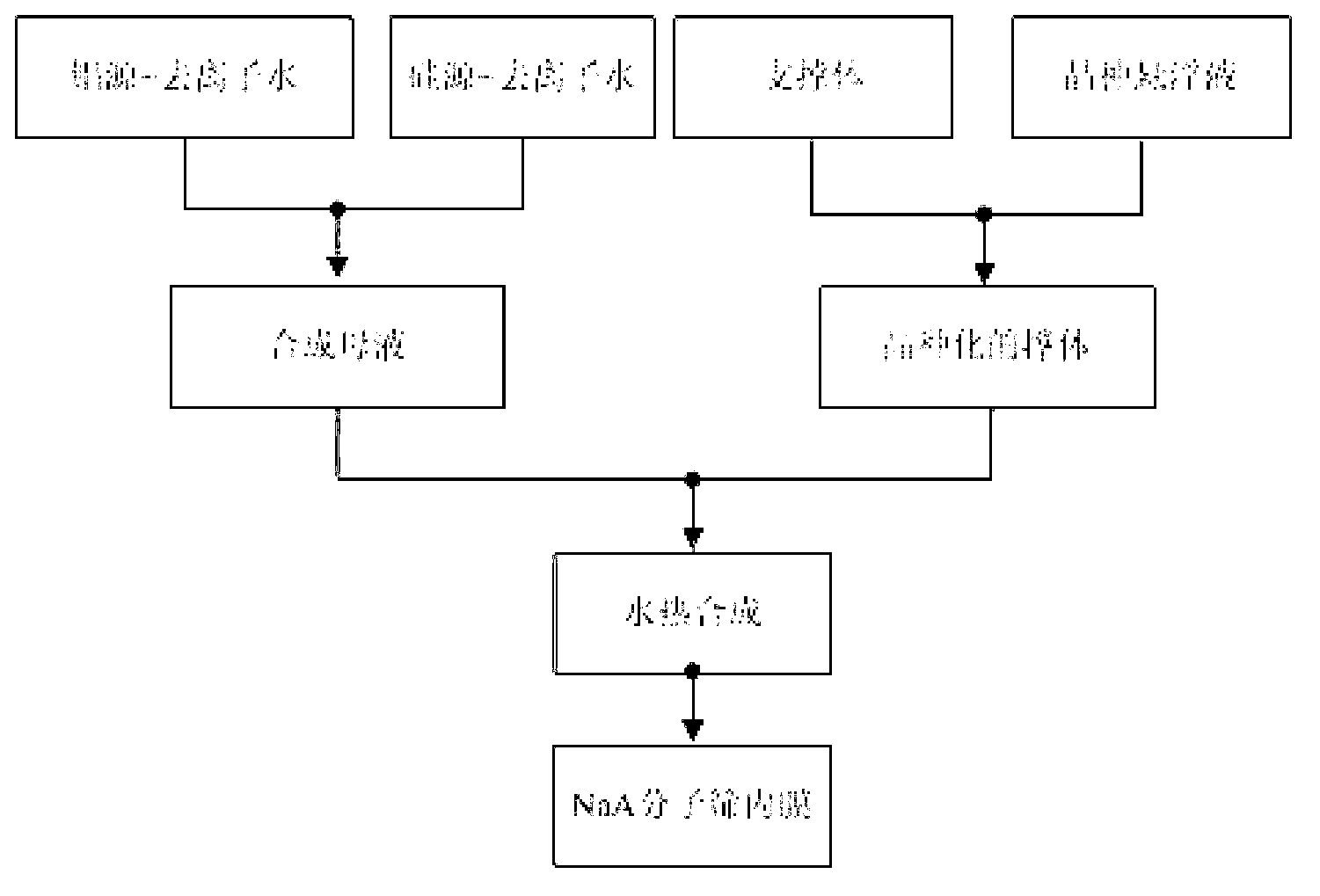

[0033] The preparation device of NaA molecular sieve inner membrane provided by the invention is as figure 1 As shown, the preparation steps are as follows figure 2 shown.

[0034] Step 1: Preparation of seeded support

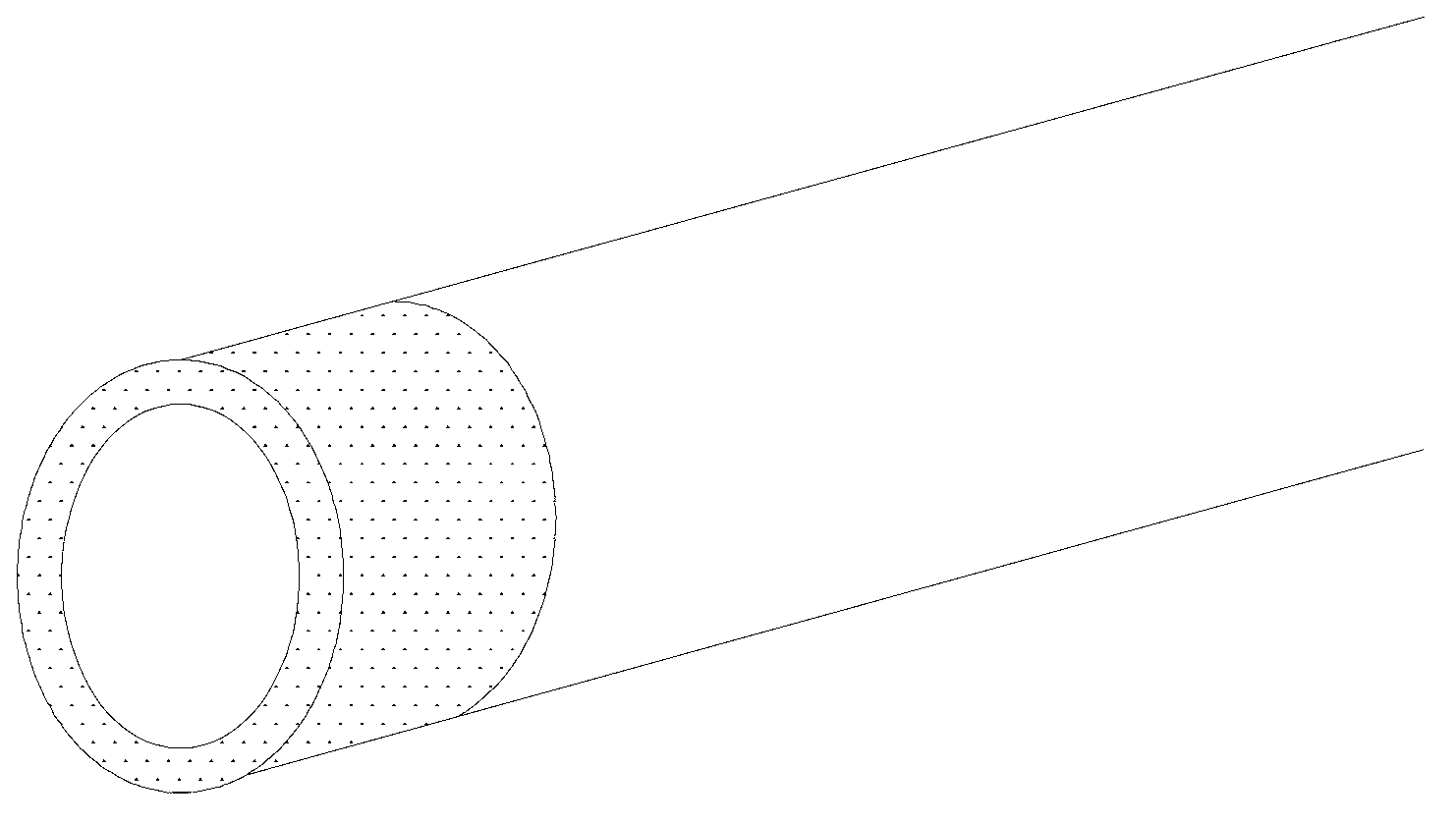

[0035] Such as figure 1 As shown, weigh 10 g of NaA molecular sieve seeds with an average particle size of about 2 μm, disperse them in 990 g of deionized water, and place them in the seed tank 2 on the stirrer 1, stir for 10 h and then ultrasonically disperse for 30 min to obtain NaA type Molecular sieve seed crystal suspension 3, the concentration of the seed crystal suspension is 10g / L; the mullite single-tube support body 5 with polytetrafluoroethylene raw material tape wrapped around the outer surface of both ends of the seal is fixed in the membrane module 4, and the single The end sealing method of the tube support body is as follows: image 3 As shown in the shaded part in the middle, the end surface of one end of the single tube and the outer wal...

Embodiment 2

[0039] Step 1: Preparation of seeded support

[0040] Weigh 10 g of NaA molecular sieve seed crystals with an average particle size of about 2 μm, disperse them in 990 g of deionized water, and ultrasonically disperse them for 30 minutes after stirring for 10 hours to obtain a NaA molecular sieve seed crystal suspension, the concentration of which is 10 g / L; The mullite five-channel support body (thickness: 50 μm) wrapped with polytetrafluoroethylene raw material tape on the outer surface of both ends is fixed in the membrane module, and then the NaA molecular sieve suspension is transported to the In the inner cavity of the support body 5, the molecular sieve suspension is circulated back into the seed crystal tank, and after the control cycle time is 10s, the seed crystal suspension in the inner cavity of the support body and the pipeline is emptied in the reverse direction (the direction of flow of the suspension when the crystal is coated) On the contrary), the support bod...

Embodiment 3

[0044] Step 1: Preparation of seeded support

[0045] Weigh 100 g of NaA molecular sieve seed crystals with an average particle size of about 10 μm, disperse them in 900 g of deionized water, and ultrasonically disperse them for 30 minutes after stirring for 10 hours to obtain a NaA molecular sieve seed crystal suspension, the concentration of which is 100 g / L; The aluminum oxide four-channel support body with both ends sealed and wrapped with polytetrafluoroethylene raw material tapes is fixed in the membrane module, and then the NaA molecular sieve suspension is transported to the inner cavity of the support body at a flow rate of 0.01m / s through a slurry pump. In the seed crystal tank where the molecular sieve suspension is circulated, after 30 seconds of circulation, the seed crystal suspension in the inner cavity of the support and the pipeline is emptied in the reverse direction, and then the support is taken out and placed in an oven to dry for later use.

[0046] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com