Porous metal nanometer granular catalyst and preparation method thereof

An alloy nano-particle and nano-particle technology is applied in the field of porous cobalt/nickel nano-particle catalyst and its preparation, which can solve the problems of small specific surface area and poor catalytic performance of the catalyst, so as to improve the reaction yield, reduce the reaction temperature and the reaction time. The effect of less pressure and fewer steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

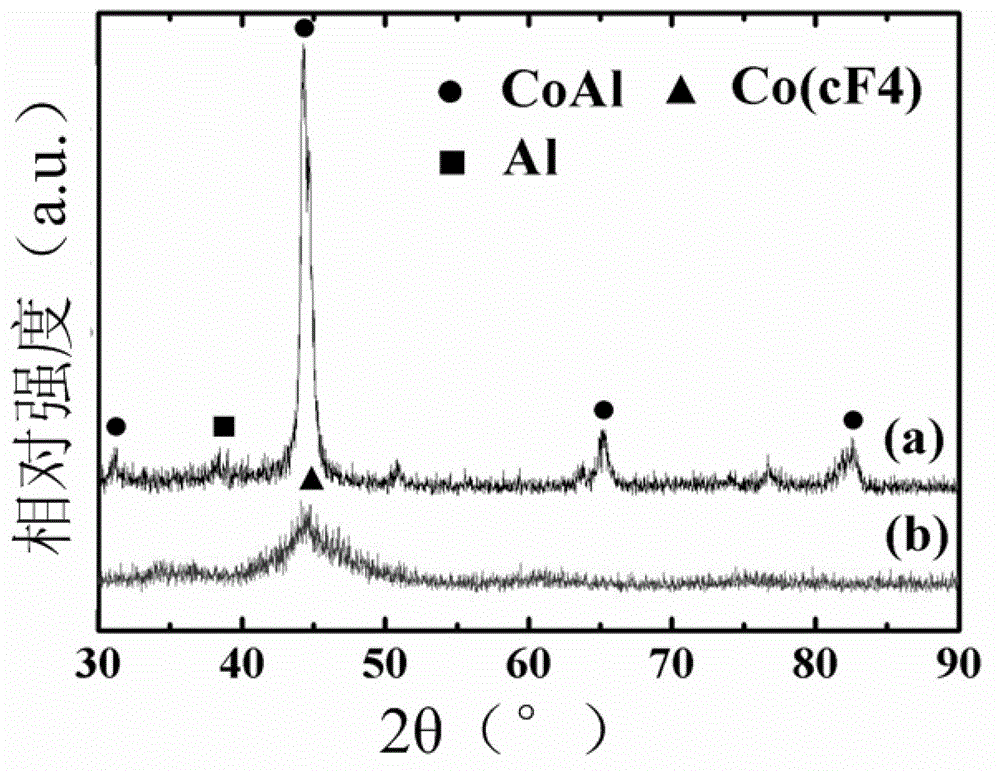

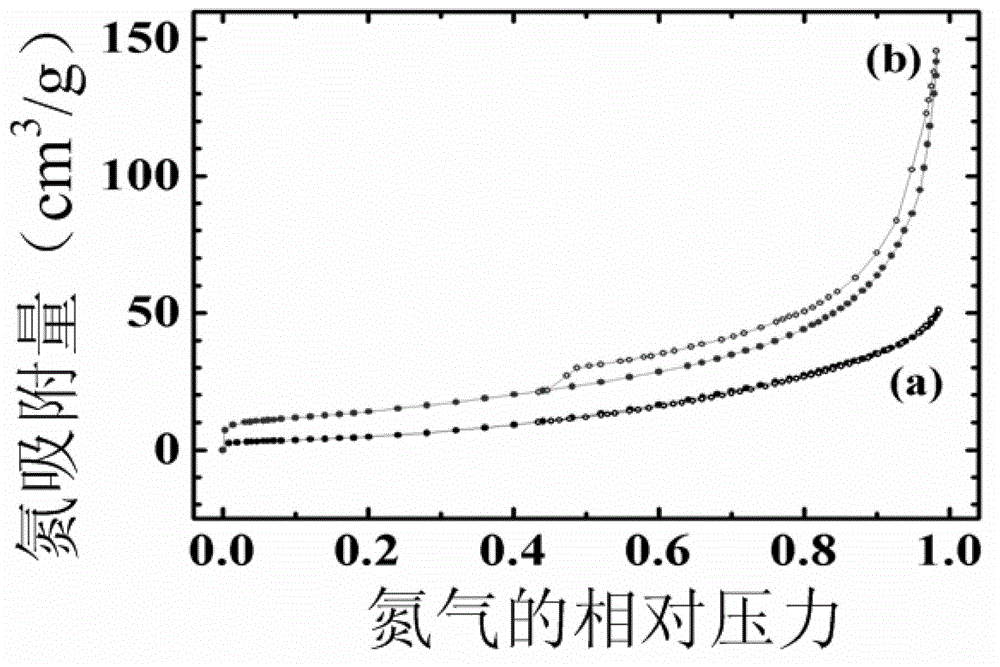

Embodiment 1

[0078] The preparation of the porous cobalt metal nanoparticle catalyst comprises the following steps:

[0079] Step 1: Melting cobalt aluminum alloy ingots

[0080] Step 101: Cobalt metal with a mass percentage purity of 99.9% and metal aluminum with a mass percentage purity of 99.9% are smelted to obtain a first cobalt-aluminum alloy ingot;

[0081] Melting conditions include: arc working current 300A, arc center temperature is about 5700°C, melting time is 5 minutes, and the melting process is kept in an argon atmosphere of 0.08MPa; the purity of argon is 99.999% (volume percentage);

[0082] Dosage: Add 2.2g of cobalt metal to 1g of metal aluminum;

[0083] Step 102: cut off the arc, roll the first cobalt-aluminum alloy ingot, and continue melting under the melting conditions to obtain the second cobalt-aluminum alloy ingot;

[0084] Melting conditions include: arc working current 300A, arc center temperature is about 5700°C, melting time is 5 minutes, and the melting pr...

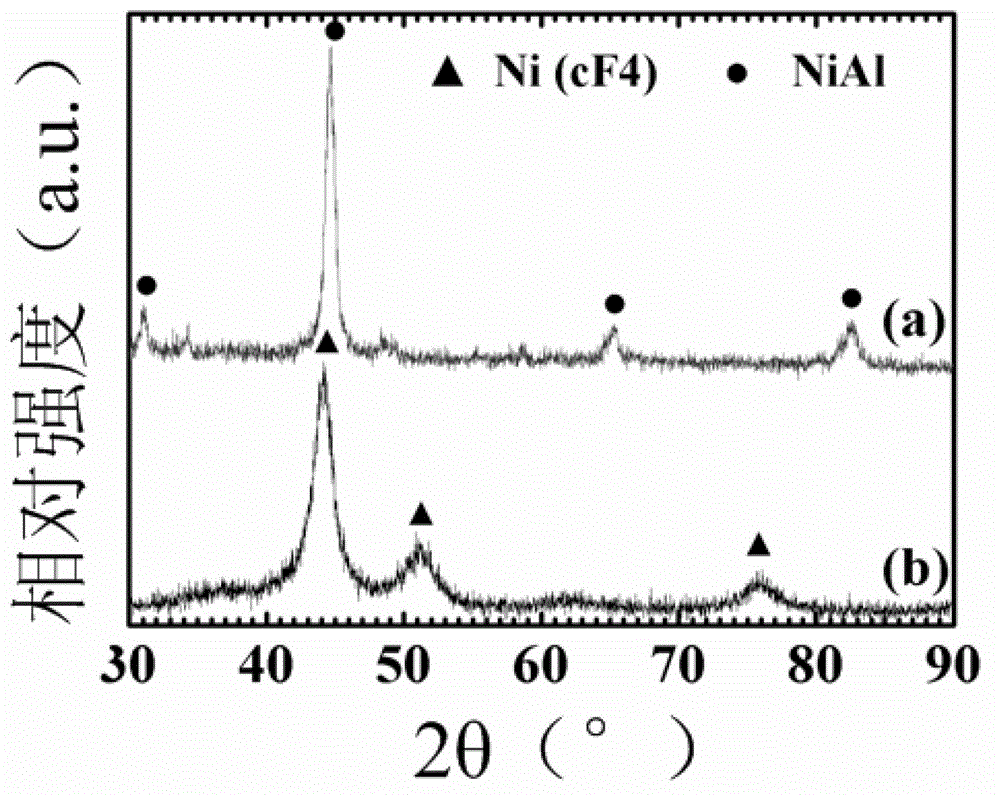

Embodiment 2

[0116] The preparation of the porous nickel metal nanoparticle catalyst comprises the following steps:

[0117] Step 1: Melting nickel-aluminum alloy ingots

[0118] Step 101: Under smelting conditions, metallic nickel with a mass percentage purity of 99.9% and metallic aluminum with a mass percentage purity of 99.9% is smelted to obtain a first nickel-aluminum alloy ingot;

[0119] Melting conditions include: arc working current 350A, arc center temperature is about 5900°C, melting time is 3 minutes, and the melting process is kept in an argon atmosphere of 0.06MPa; the purity of argon is 99.999% (volume percentage);

[0120] Dosage: Add 1.5g of metallic nickel to 1g of metallic aluminum;

[0121] Step 102: cut off the arc, roll the first nickel-aluminum alloy ingot, and continue melting under the melting conditions to obtain the second cobalt-nickel alloy ingot;

[0122] Melting conditions include: arc working current 350A, arc center temperature is about 5900°C, melting t...

Embodiment 3

[0154] The preparation of the porous cobalt metal nanoparticle catalyst comprises the following steps:

[0155] Step 1: Melting cobalt aluminum alloy ingots

[0156] Step 101: Cobalt metal with a mass percentage purity of 99.9% and metal aluminum with a mass percentage purity of 99.9% are smelted to obtain a first cobalt-aluminum alloy ingot;

[0157] Melting conditions include: arc working current 200A, arc center temperature is about 5400°C, melting time is 10 minutes, the melting process is kept in 0.1MPa argon atmosphere; the purity of argon is 99.999% (volume percentage);

[0158] Dosage: Add 3g of metal cobalt to 1g of metal aluminum;

[0159] Step 102: cut off the arc, roll the first cobalt-aluminum alloy ingot, and continue melting under the melting conditions to obtain the second cobalt-cobalt alloy ingot;

[0160] Melting conditions include: arc working current 200A, arc center temperature is about 5400°C, melting time is 10 minutes, the melting process is kept in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com