Nickel/copper catalyst and preparation method thereof, and method for directly preparing 1,2-hexanediol from cellulosan by using nickel/copper catalyst

A technology of copper catalyst and celloglycan, which is applied in the field of nickel/copper catalyst and its preparation, can solve the problems of slow enzyme-catalyzed reaction rate, serious environmental pollution, complex production process, etc., and achieve easy recovery, simple preparation process and catalytic activity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

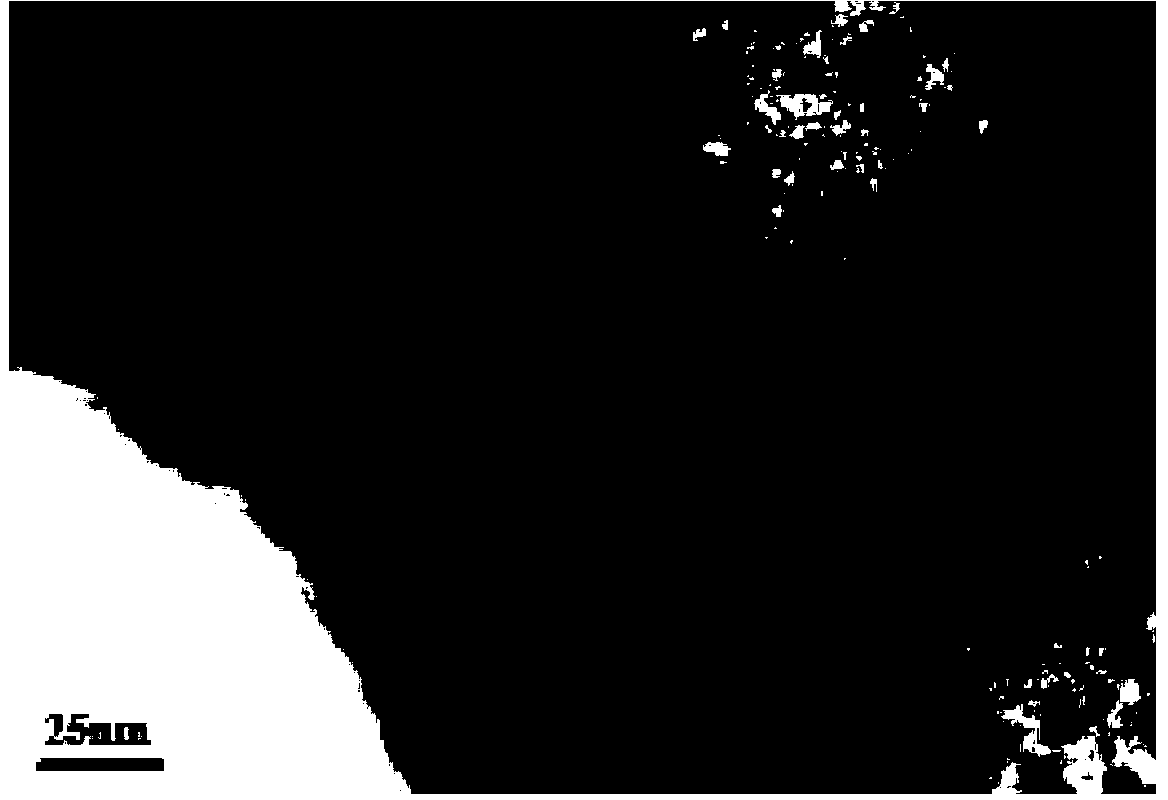

Image

Examples

Embodiment 1

[0042] Embodiment 1: the preparation of catalyst 15Ni-15Cu / AC-KOH

[0043] Preparation of nickel / copper precursor solution:

[0044] Weigh 29.56g of nickel nitrate hexahydrate, dissolve it in 50mL of distilled water, and, under stirring, add 20mL of ethylenediamine according to the molar ratio of nickel nitrate hexahydrate: ethylenediamine is 1:3 (a little excess of ethylenediamine) , Add ethylenediamine dropwise to the nickel nitrate solution at a rate of 2-5 drops / s, preferably 3 drops / s, and the solution gradually changes from green to purple. After the dropwise addition, the solution was transferred into a 100mL volumetric flask, constant volume, and left to stand for about 1 hour to obtain an ethylenediamine-nickel precursor solution with a concentration of 1.0moL / L.

[0045] Copper ethylenediamine was prepared in the same manner.

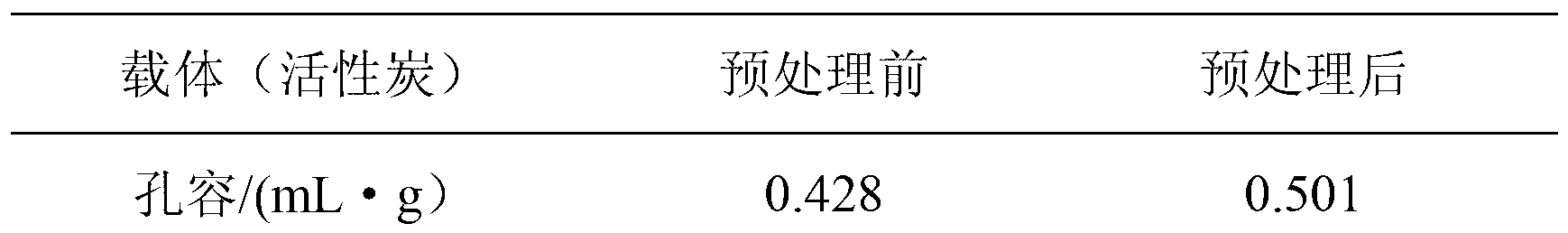

[0046] Preparation of activated carbon support:

[0047] 1. Using biomass such as chitosan, cellulose, cotton or corncob as raw mater...

Embodiment 2

[0052] Embodiment 2: the preparation of catalyst 15Ni-15Cu / AC-formic acid

[0053] The catalyst 15Ni-15Cu / AC-formic acid was prepared in the same manner as in Example 1, except that formic acid was used instead of KOH in the preparation of the activated carbon carrier, that is, the catalyst carrier activated carbon was pretreated with formic acid.

Embodiment 3

[0054] Embodiment 3: the preparation of catalyst 15Ni-15Cu / AC-HF

[0055] Catalyst 15Ni-15Cu / AC-HF was prepared in the same manner as in Example 1, except that hydrofluoric acid was used instead of KOH in the preparation of the activated carbon carrier, that is, the catalyst carrier activated carbon was pretreated with hydrofluoric acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com