Preparation method of carbon nanometer tube-graphene composite material

A carbon nanotube and composite material technology, applied in the field of nanocomposite material preparation and application, can solve the problems of many graphene defects, limited growth, difficult interface contact, etc., to achieve simple process, strong interface contact, easy batch production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

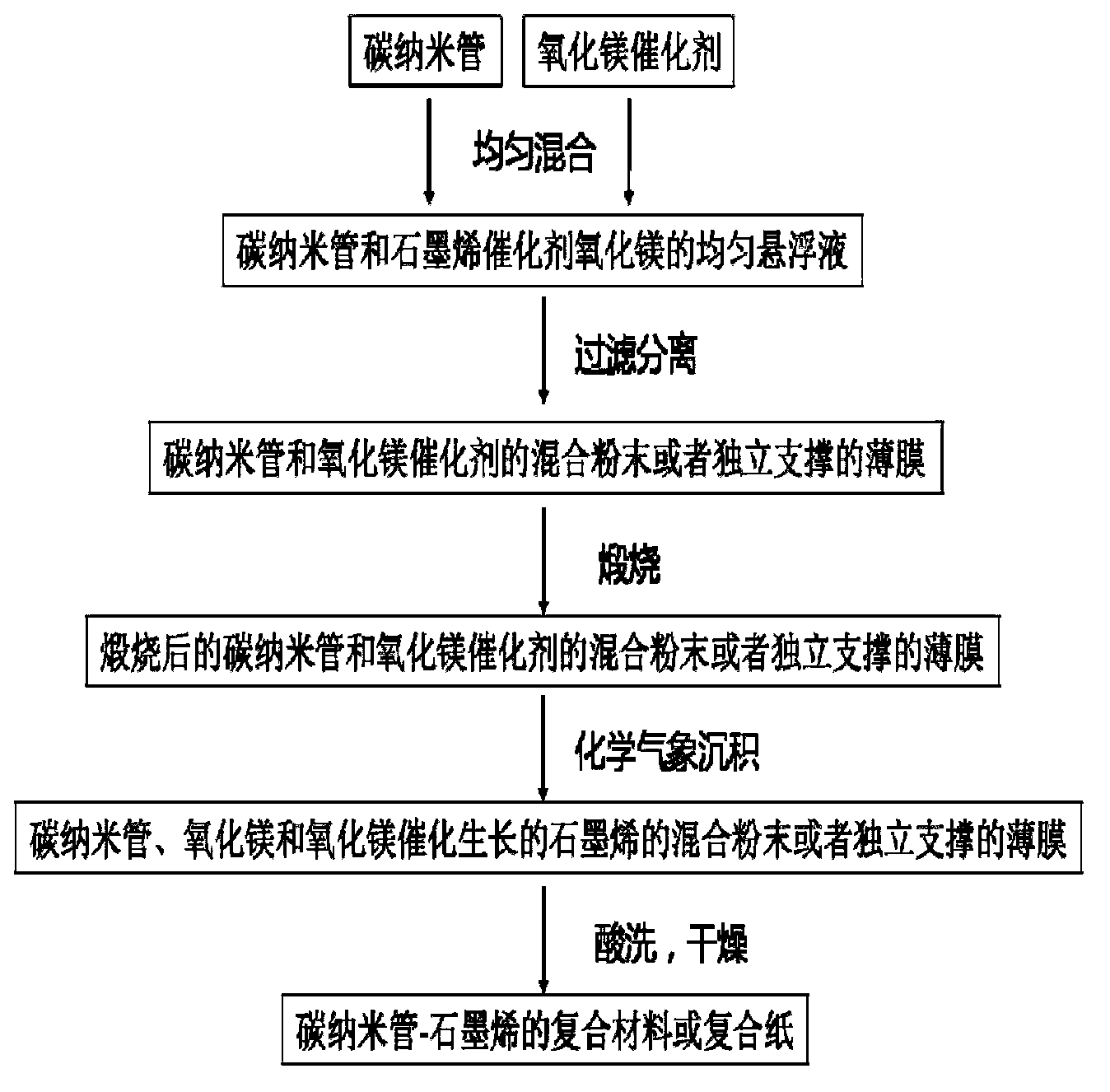

Method used

Image

Examples

Embodiment 1

[0034] Ultrasonic dispersion of 5.0 g of magnesium hydroxide and 5.0 g of block copolymer P123 in 1 L of deionized water, and spray drying to obtain a magnesium oxide powder product with a particle size of ~1000 nm. The purified vermiculite array multi-walled carbon nanotubes were dispersed in the ionic liquid, and 50 g of a carbon nanotube suspension in which the mass percentage of the carbon nanotubes accounted for 0.6% in the solution was prepared. Add 1.0 g of magnesia powder catalyst to the above suspension, and stir evenly to form a mixture suspension of the two. The suspension of the above mixture is filtered and separated to form a powder product in which purified multi-walled carbon nanotubes and graphene catalyst particles are uniformly mixed. The mixed powder was put into 550° C. of nitrogen for calcination for 1 hour, then the temperature was raised to 900° C., and methane was introduced as a carbon source for vapor-phase chemical deposition for 20 minutes. The pr...

Embodiment 2

[0036]2.0 g of magnesium oxide particles were directly ultrasonically dispersed in 2 L of deionized water, filtered and dried to obtain magnesium oxide powder with a particle size distribution of 50-200 nm. Disperse the raw aggregated multi-walled carbon nanotube particles in ethanol, and prepare 50 g of agglomerated carbon nanotube particle suspension in which the mass percentage of carbon nanotubes accounts for 2.0% in the solution. Add 1.0 g of magnesium oxide powder to the above solution, and stir to form a mixture suspension. The suspension of the above mixture is filtered and separated to obtain a powder product in which the agglomerated carbon nanotubes and the magnesium oxide catalyst are uniformly mixed. This powder product is put into the nitrogen of 500 DEG C and calcined for 1 hour, then continues to heat up to 900 DEG C, feeds ethylene as carbon source and carries out gas-phase chemical deposition for 2 hours. Soak the obtained powder product in a hydrochloric ac...

Embodiment 3

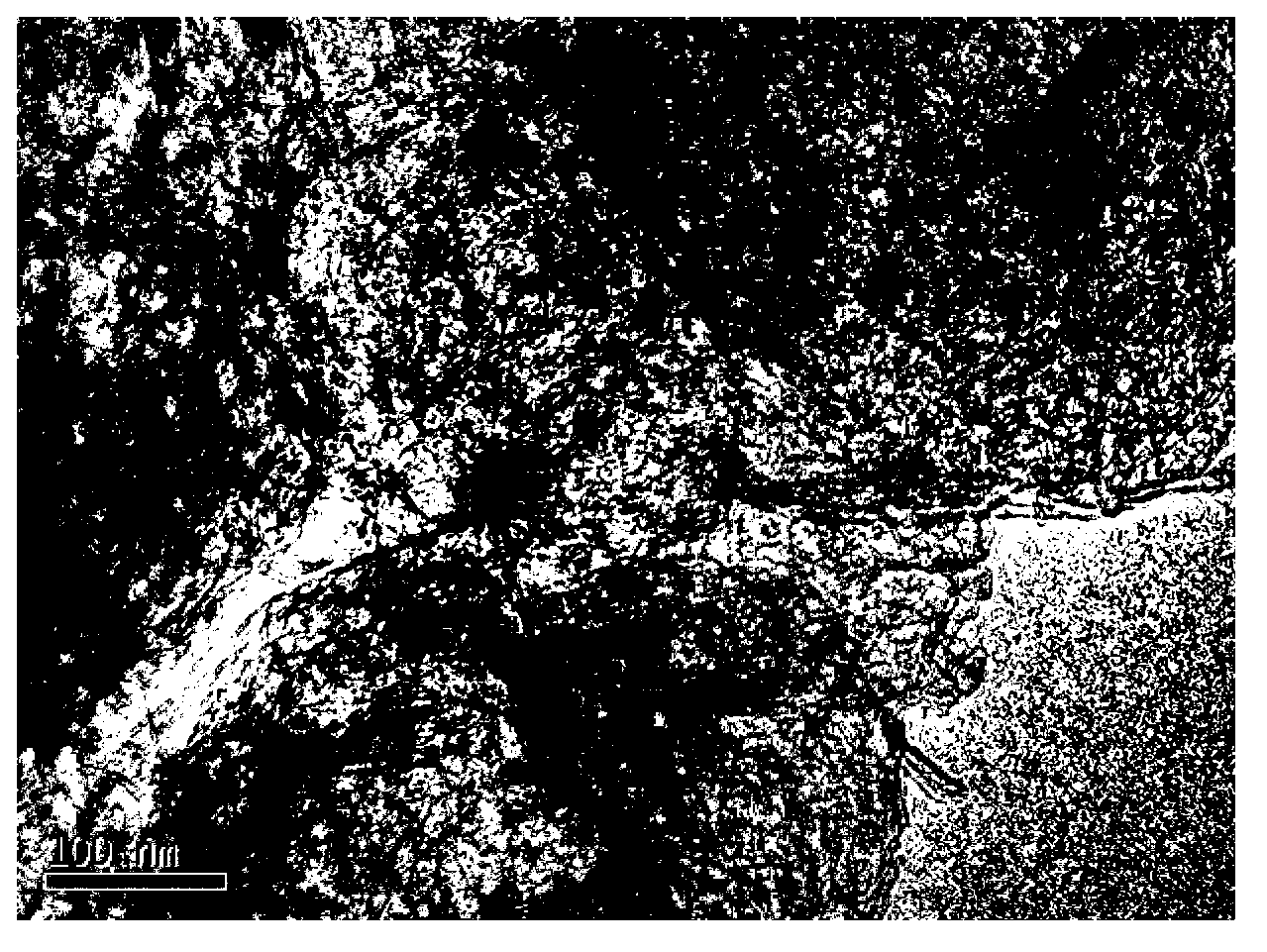

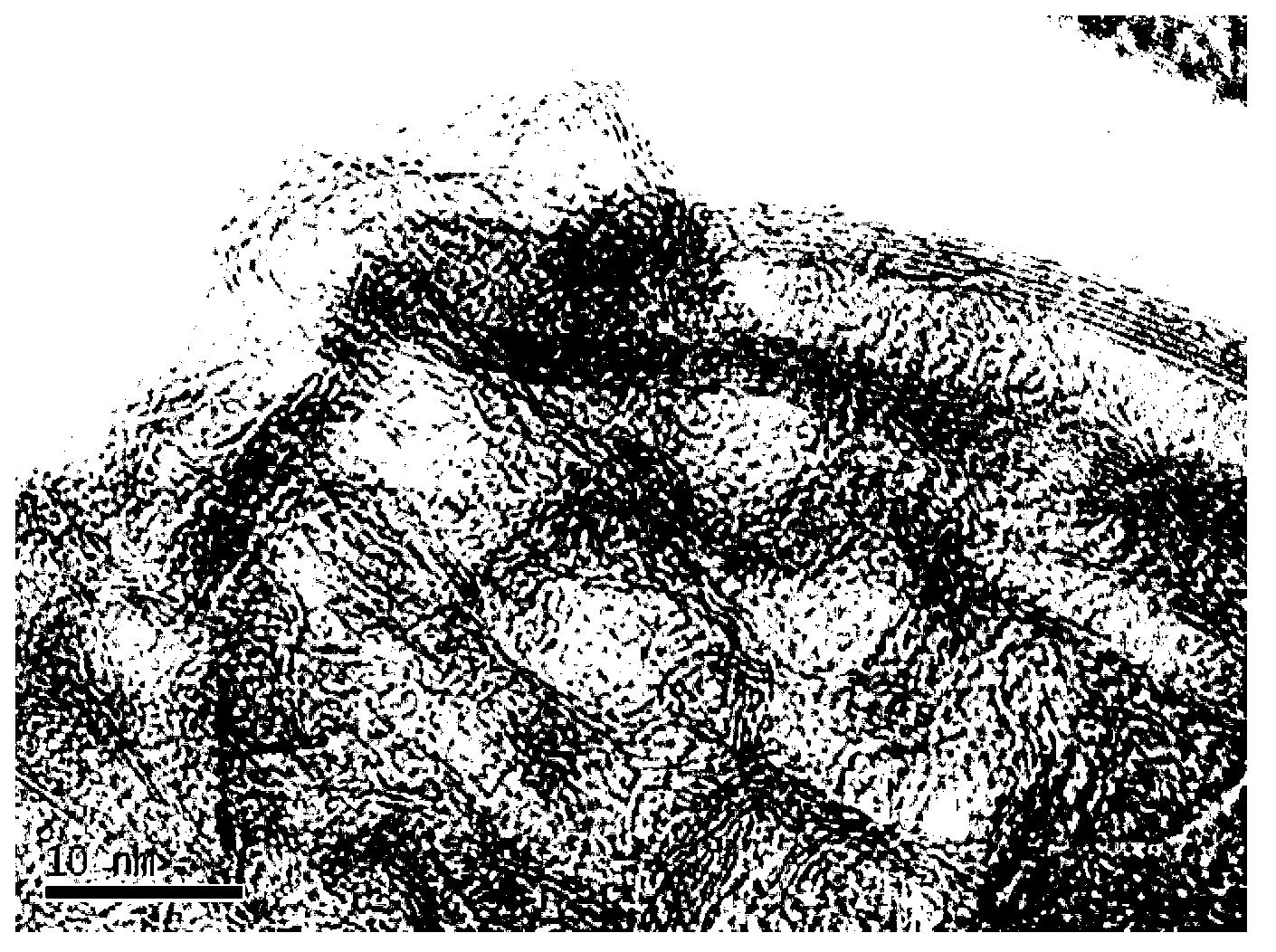

[0038] 1.0 g of magnesium oxide particles and 5.0 g of block copolymer F127 were ultrasonically dispersed in 1 L of deionized water with a high-power ultrasonic rod, filtered and dried to obtain magnesium oxide nanoparticles with a particle size distribution of 10-100 nm. Disperse the purified single-walled carbon nanotubes in nitrogen methyl pyrrolidone, and prepare 50 g of a carbon nanotube suspension in which the mass percentage of uniformly dispersed carbon nanotubes accounts for 0.05% in the solution. Add 0.2 g of magnesium oxide particles to the above suspension, mix well to form a mixture suspension. The above mixture suspension was filtered to form a free-standing membrane. The film was calcined in argon at 600°C for 1 hour, then heated to 800°C, and passed through propyne for vapor phase chemical deposition for 5 minutes. The film product that obtains is soaked in the hydrochloric acid solution of mass percentage composition 14%, removes magnesium oxide catalyst part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com