Application of fly ash in construction mortar

A technology for fly ash and construction, applied in the application field of fly ash in construction mortar, can solve the problems of increasing the production cost of retarder, high cost of environmental pollution control, fluctuation of corn price, etc., and achieves remarkable environmental protection efficiency and water resistance. Excellent impermeability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

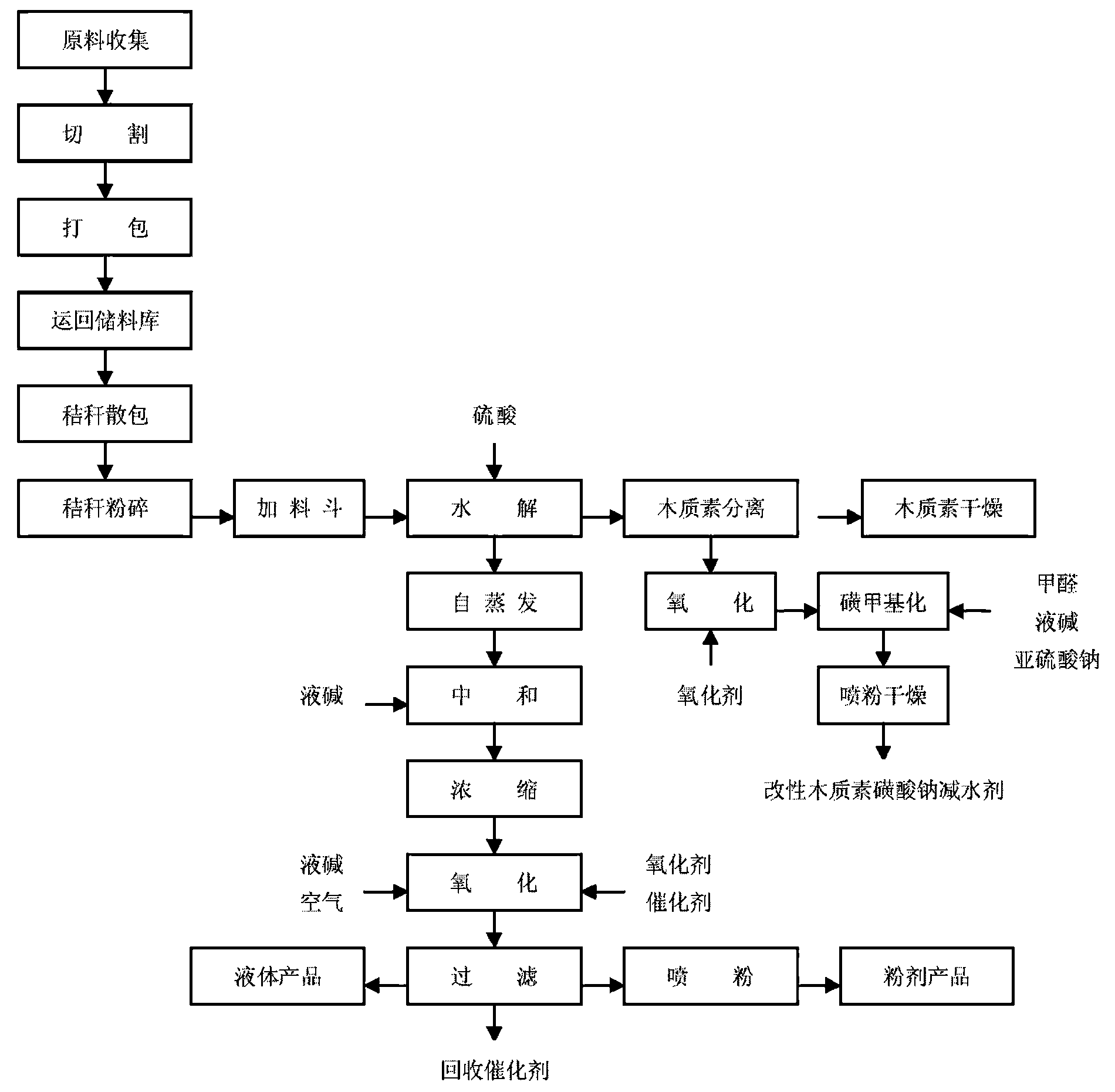

[0119] like figure 1 As shown, the application of fly ash in construction mortar, its raw materials are expressed in kg / m 3 Calculated, including the components in the following weight ratios.

[0120] Cement 400.

[0121] Thickening powder 50.

[0122] Fly Ash 130.

[0123] Sand 1500.

[0124] Retarder 8.

[0125] Water 280.

[0126] The preparation method of the retarder is carried out in sequence as follows.

[0127] The crushed straw and 0.2% sulfuric acid are put into the hydrolysis pot at a mass ratio of 1:5, heated to 145 degrees with steam, kept for 50 minutes for hydrolysis, filtered, and the filtrate is added to the new straw powder for the second hydrolysis, and the filter residue is added Its 0.2% sulfuric acid solution of 5 times the mass was hydrolyzed for 60 minutes at a temperature of 175 degrees, filtered, and the filtrate was hydrolyzed with a new primary hydrolysis slag to obtain a higher concentrated sugar solution. Mix the first-stage secondary hyd...

Embodiment 3

[0130] like figure 1 As shown, the application of fly ash in construction mortar, its raw materials are expressed in kg / m 3 Calculated, including the components in the following weight ratios.

[0131] Cement 250.

[0132] Thickening powder 30.

[0133] fly ash 110.

[0134] Sand 1300.

[0135] Retarder 6.

[0136] water 260.

[0137] The preparation method of the retarder is carried out in sequence as follows.

[0138] The crushed straw and 0.4% sulfuric acid are put into the hydrolysis pot according to the mass ratio of 1:4.5, heated to 150 degrees with steam, kept for hydrolysis for 45 minutes, filtered, and the filtrate is added to the new straw powder for the second hydrolysis, and the filter residue is added Its 0.4% sulfuric acid solution of 5 times of mass was hydrolyzed for 70 minutes at a temperature of 175 degrees, filtered, and the filtrate was hydrolyzed with a new primary hydrolysis slag to obtain a relatively concentrated sugar solution. Mix the first-stag...

Embodiment 4

[0141] like figure 1 As shown, the application of fly ash in construction mortar, its raw materials are expressed in kg / m 3 Calculated, including the components in the following weight ratios.

[0142] cement 310.

[0143] Thickened powder 42.

[0144] fly ash 113.

[0145] Sand 1350.

[0146] Retarder 5.

[0147] water 268.

[0148] The preparation method of the retarder is carried out in sequence as follows.

[0149] The crushed straw and 1.95% sulfuric acid are put into the hydrolysis pot at a mass ratio of 1:5, heated to 150 degrees with steam, kept for 40 minutes for hydrolysis, filtered, and the filtrate is added to the new straw powder for the second hydrolysis, and the filter residue is added Its 1.8% sulfuric acid solution of 5 times of mass was hydrolyzed for 50 minutes at a temperature of 180 degrees, filtered, and the filtrate was hydrolyzed with a new primary hydrolysis slag to obtain a higher concentrated sugar solution. Mix the first-stage secondary hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com