Beta-dicalcium silicate porous biological ceramic bracket and preparation method and application thereof

A technology of bioceramics and dicalcium silicate, applied in ceramic products, applications, and other household appliances, can solve problems such as lack of strength, achieve improved material exchange rate and efficiency, strong plasticity, and controllable product shape and size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

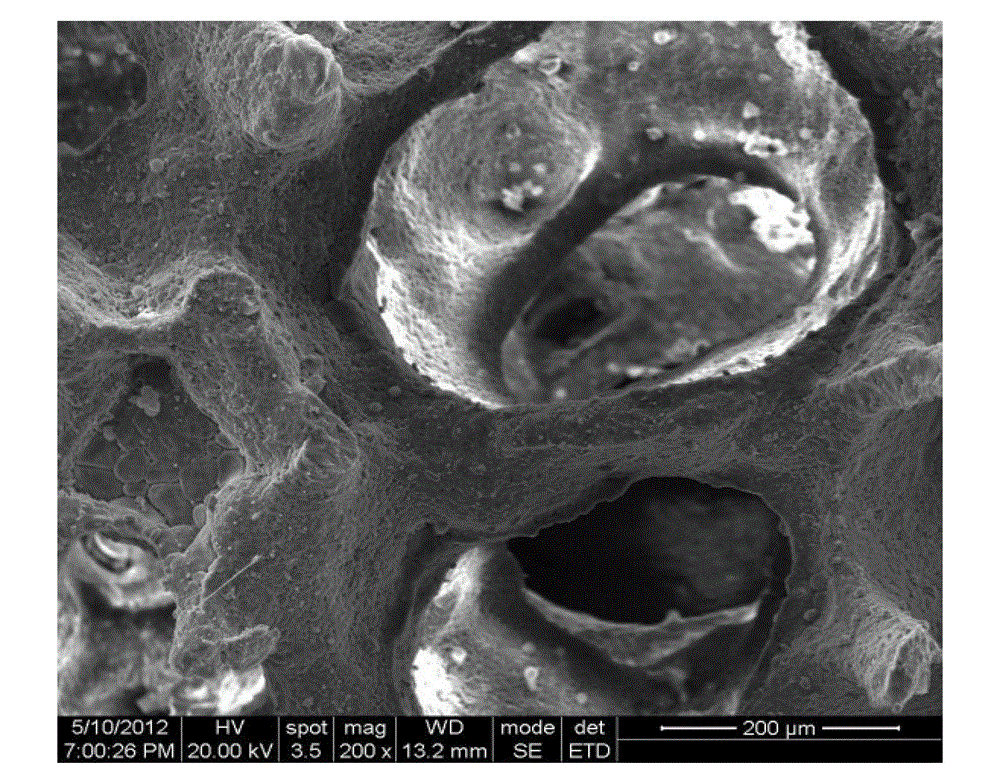

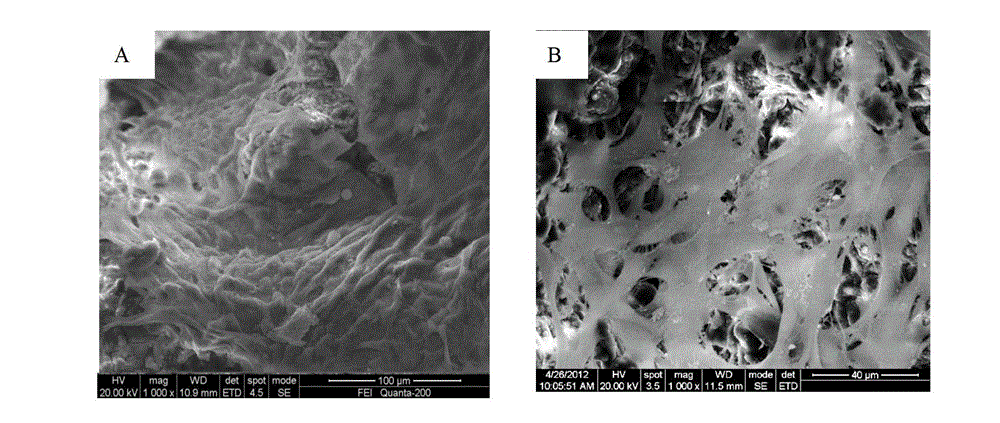

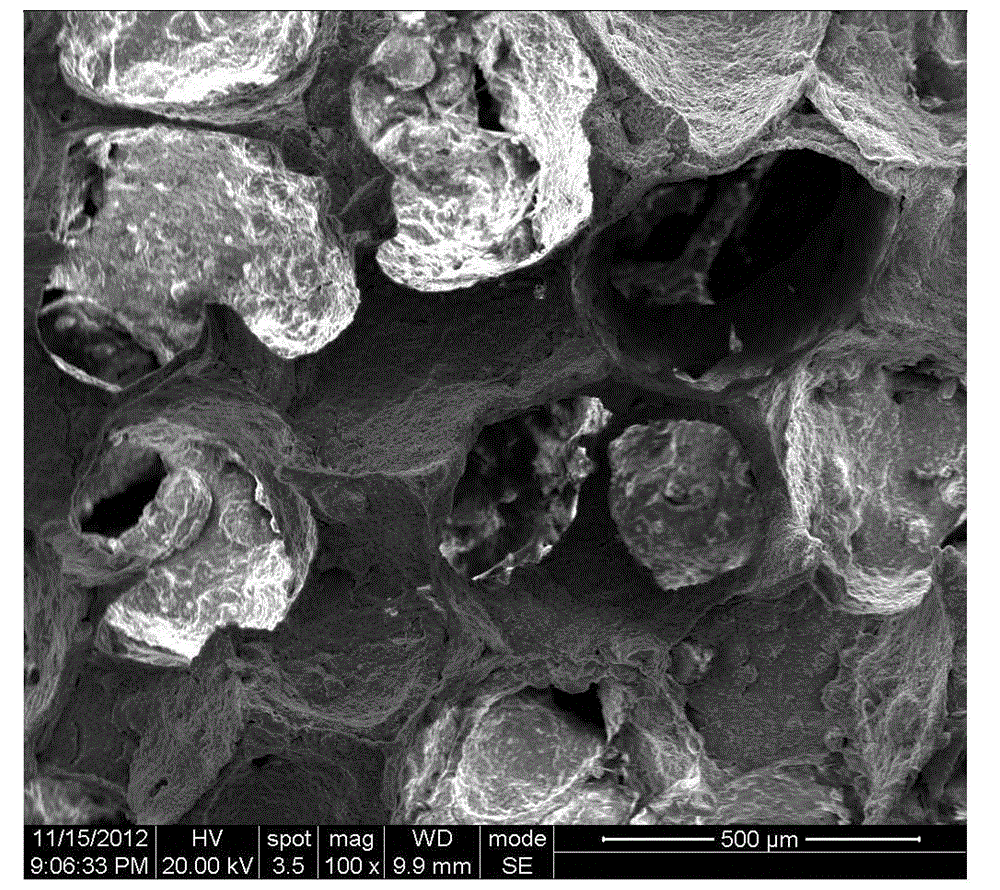

[0035] a kind of like figure 1 The β-dicalcium silicate porous bioceramic support of the present invention is shown. The β-dicalcium silicate porous bioceramic support is made of porous organic polyurethane foam as a precursor, which is impregnated and sintered.

[0036] Such as figure 2 The preparation method of the shown β-dicalcium silicate porous bioceramic support of the present invention comprises the following steps:

[0037] (1) Precursor template processing: According to the shape and size required by the product, process the polyurethane sponge to obtain a cylindrical porous scaffold template with a diameter of about 19mm and a thickness of about 10mm; then immerse the template in 10% NaOH solution Soak in water for 6 hours, then soak the template in distilled water for 12 hours, take it out and dry it for later use.

[0038] (2) Preparation of powder: CaCO 3 and SiO 2 The molar ratio is 2:1, and tricalcium phosphate (TCP) with a mass of 0.8% of the above powder...

Embodiment 2

[0047] This embodiment adopts another preparation method of the β-dicalcium silicate porous bioceramic support of the present invention, comprising the following steps:

[0048] (1) Precursor template processing: According to the shape and size required by the product, process the polyurethane sponge to obtain a cylindrical porous scaffold template with a diameter of about 19mm and a thickness of about 10mm; then immerse the template in 10% NaOH solution Soak in water for 6 hours, then soak the template in distilled water for 12 hours, take it out and dry it for later use.

[0049] (2) Preparation of powder: CaCO 3 and SiO 2 The molar ratio is 2:1, and tricalcium phosphate (TCP) with a mass of 2.2% of the above powder is added as a stabilizer. After ball milling, it was immediately taken out and dried through a 100-mesh sieve for later use.

[0050] (3) Dipping and slurrying: Weigh the mixed powder in step (2), and add 3.5% sodium carboxymethylcellulose (CMC) as a binder. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com