Seaweed amino acid composite liquid manure and preparation method and application thereof

A technology of compound liquid and amino acid, applied in the application, fertilization device, fertilizer mixture and other directions, can solve the problems of low concentration of alginic acid and amino acid, and achieve the effect of strong physiological activity, improving crop quality and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

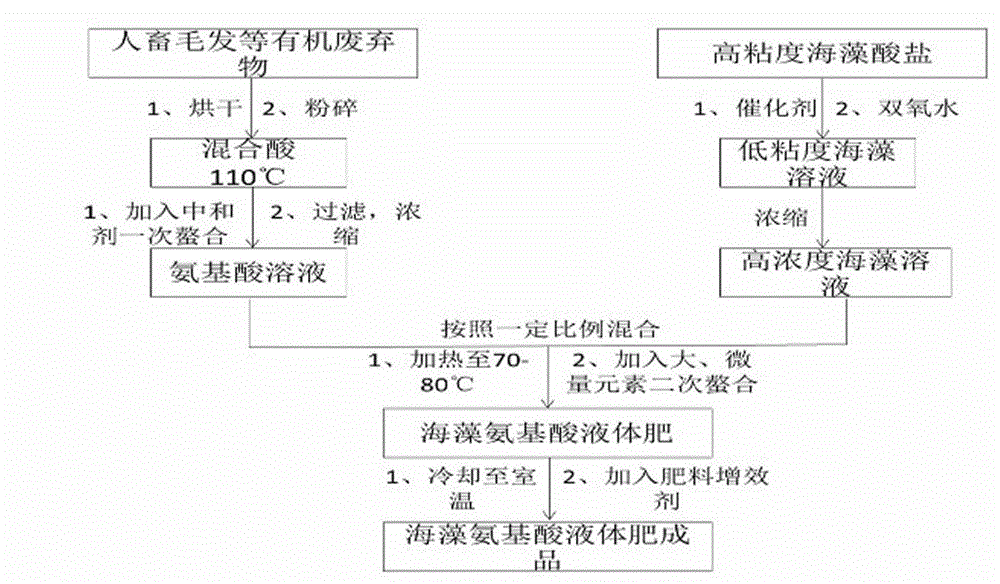

Method used

Image

Examples

Embodiment 1

[0046] (1) Degradation of alginate: Weigh 375 parts of water in the reactor and raise the temperature to 65°C, add 0.06 parts of ferrous sulfate, 110 parts of sodium alginate (polymerization degree of 600 and G / M of 1.0), 30wt% hydrogen peroxide 30 parts, stirred and hydrolyzed for 5 hours, added 0.1 part of sodium bisulfite, concentrated to an alginic acid solution with a final alginic acid concentration of 40g / 100mL.

[0047](2) Amino acid primary chelation: add 300 parts of mixed acid obtained by mixing 20wt% hydrochloric acid, 20wt% sulfuric acid and 30wt% phosphoric acid at a mass ratio of 6:2:2 to the reactor, then add 150 parts of pig hair, and heat up to React at 110°C for 6 hours; when the temperature drops to 85°C, add 1 part of EDTA, 8 parts of magnesium oxide, and 4 parts of calcium oxide for chelation for 2 hours. After the reaction is completed, filter and concentrate to obtain a 30wt% amino acid solution.

[0048] (3) Secondary chelation: Weigh 57 parts of the a...

Embodiment 2

[0050] (1) Degradation of alginate: same as Example 1. (1).

[0051] (2) Amino acid primary chelation: add 300 parts of mixed acid obtained by mixing 20wt% hydrochloric acid, 20wt% sulfuric acid and 30wt% phosphoric acid at a mass ratio of 8:1:1 to the reactor, then add 150 parts of pig hair, and heat up to React at 110°C for 6 hours; when the temperature drops to 85°C, add 1 part of EDTA, 8 parts of magnesium oxide, and 4 parts of calcium oxide for chelation for 2 hours. After the reaction is completed, filter and concentrate to obtain a 30wt% amino acid solution.

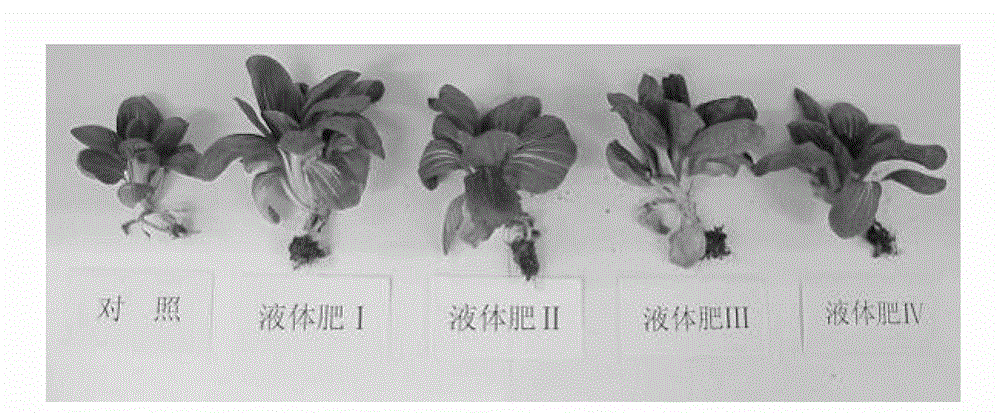

[0052] (3) secondary chelation: with embodiment 1. (3), this product is figure 2 Liquid fertilizer II in.

Embodiment 3

[0054] (1) Degradation of alginate: Weigh 375 parts of water in the reactor and raise the temperature to 75°C, add 0.06 parts of ferrous sulfate, 150 parts of sodium alginate (polymerization degree of 700 and G / M of 0.8), 30wt% hydrogen peroxide 45 parts, stirred and hydrolyzed for 5 hours, added 0.1 part of sodium bisulfite, concentrated to an alginic acid solution with a final alginic acid concentration of 50 g / 100 mL.

[0055] (2) Amino acid primary chelation: add 300 parts of mixed acid obtained by mixing 20wt% hydrochloric acid, 20wt% sulfuric acid and 30wt% phosphoric acid at a mass ratio of 8:1:1 to the reactor, then add 150 parts of hair, and heat up to 115 React at ℃ for 6 hours; when the temperature drops to 85℃, add 2 parts of EDTA-Na, 16 parts of magnesium oxide, and 8 parts of calcium oxide for chelation for 2 hours. After the reaction is completed, filter and concentrate to obtain a 30wt% amino acid solution;

[0056] (3) Secondary chelation: Weigh 47 parts of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com