Wastewater zero discharge preparing method of thermoplastic phenolic resin

A phenolic resin and thermoplastic technology, which is applied in the field of phenolic resin preparation, can solve unsatisfactory problems, achieve the effect of no performance degradation, great environmental protection significance, and break through the environmental protection bottleneck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment is a method for preparing thermoplastic phenolic resin with zero waste water discharge, and the specific process is as follows:

[0028] Add 400g of phenol, 85g of paraformaldehyde, 3.0g of oxalic acid (20wt%), and 150g of water into a four-necked flask equipped with a stirring and condenser and mix. Heat up to boiling reflux, react for 3 hours; heat up to 110°C for dehydration reaction, then cool down to 100°C, then heat up to boiling reflux, react for 1 hour, until the resin viscosity reaches 2000mPa.s25°C, add 1.0g sodium hydroxide to adjust The pH value of the resin reaches 6, and then continues to heat up and dehydrate until the temperature reaches 160°C, and then the thermoplastic phenolic resin can be obtained. The number average molecular weight Mn of the resin is 734, the weight average molecular weight Mw is 1535, the softening point is 129°C, and the free phenol content is 4.22%.

Embodiment 2

[0030] This embodiment is a method for preparing thermoplastic phenolic resin with zero waste water discharge, and the specific process is as follows:

[0031] 500g of cresol, 100g of paraformaldehyde, 3.4g of phosphoric acid, and 150g of water were added to a four-necked flask equipped with a stirring and condenser for mixing. Heat up to boiling reflux, react for 2 hours; heat up dehydration reaction to 109°C, then cool down to 90°C, then heat up to boiling reflux, react for 2 hours, until the resin viscosity reaches 2500mPa.s25°C, add 0.8g sodium hydroxide to adjust The pH value of the resin reaches 5.8, and then continues to heat up and dehydrate until the temperature reaches 165° C., and then a thermoplastic phenolic resin can be obtained. The number average molecular weight Mn of the resin is 825, the weight average molecular weight Mw is 1788, the softening point is 135°C, and the free phenol content is 3.95%.

Embodiment 3

[0033] This embodiment is a method for preparing thermoplastic phenolic resin with zero waste water discharge, and the specific process is as follows:

[0034] Add 450g of xylenol, 90g of paraformaldehyde, 3.2g of sulfuric acid, and 150g of water into a four-necked flask equipped with a stirring and condenser and mix them. Heat up to boiling reflux, react for 4 hours; heat up dehydration reaction to 105°C, then cool down to 80°C, then heat up to boiling reflux, react for 3 hours, until the resin viscosity reaches 2300mPa.s25°C, add 0.9g of barium hydroxide to adjust The pH value of the resin reaches 5.0, and then continues to heat up and dehydrate until the temperature reaches 170°C, and then the thermoplastic phenolic resin can be obtained. The number average molecular weight Mn of the resin is 805, the weight average molecular weight Mw is 1532, the softening point is 132°C, and the free phenol content is 3.99%.

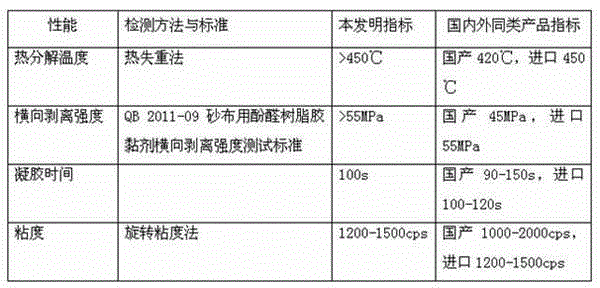

[0035] product name Thermal stability (initial th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com